Noble metal loaded nitrogen-doped bacterial cellulose as well as preparation and application thereof

A technology of bacterial cellulose and nitrogen doping, applied in catalyst activation/preparation, electrode, electrolysis process, etc., can solve the problem of high manufacturing cost, and achieve the effect of high economy, high electrocatalytic hydrogen evolution performance, and uniform nitrogen doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 10 grams of clean bacterial cellulose and place it in a beaker on average, add 80 milliliters, 1 mole / liter of hydrochloric acid solution to completely immerse the bacterial cellulose, add 50 microliters of aniline while stirring, and continue to react for 24 hours;

[0045] (2) in the beaker of step (1), add 80 milliliters of 1 mol / liter hydrochloric acid solutions that are dissolved with 0.5 gram of ammonium persulfate dropwise, continue to stir for 6 hours;

[0046] (3) the reaction product of step (2) washed the bacterial cellulose after the reaction repeatedly with deionized water and freeze-dried for 24 hours;

[0047] (4) calcining the bacterial cellulose obtained in step (3) for 2 hours under a nitrogen atmosphere of 800 degrees (heating rate 5 degrees / minute), to obtain nitrogen-doped bacterial cellulose;

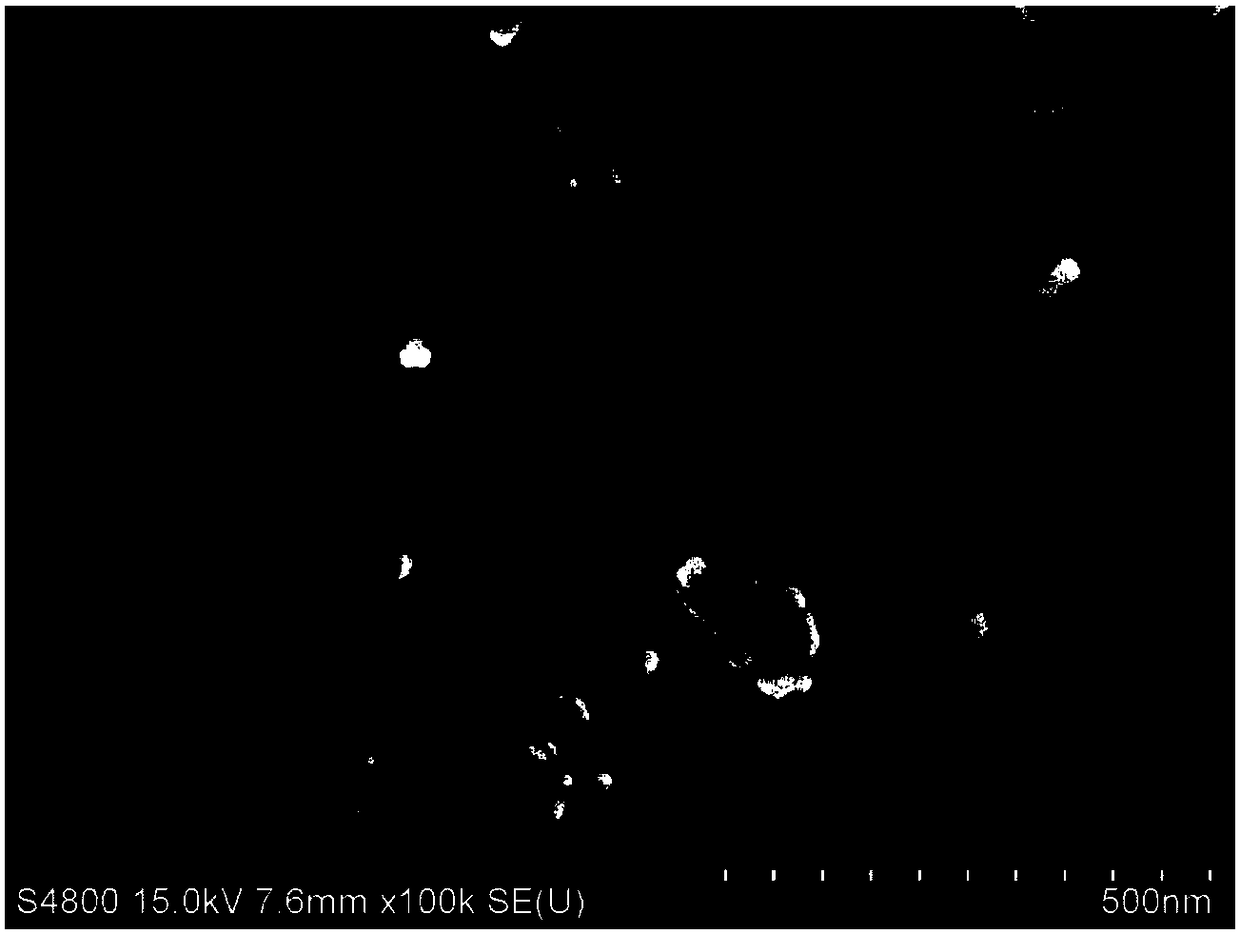

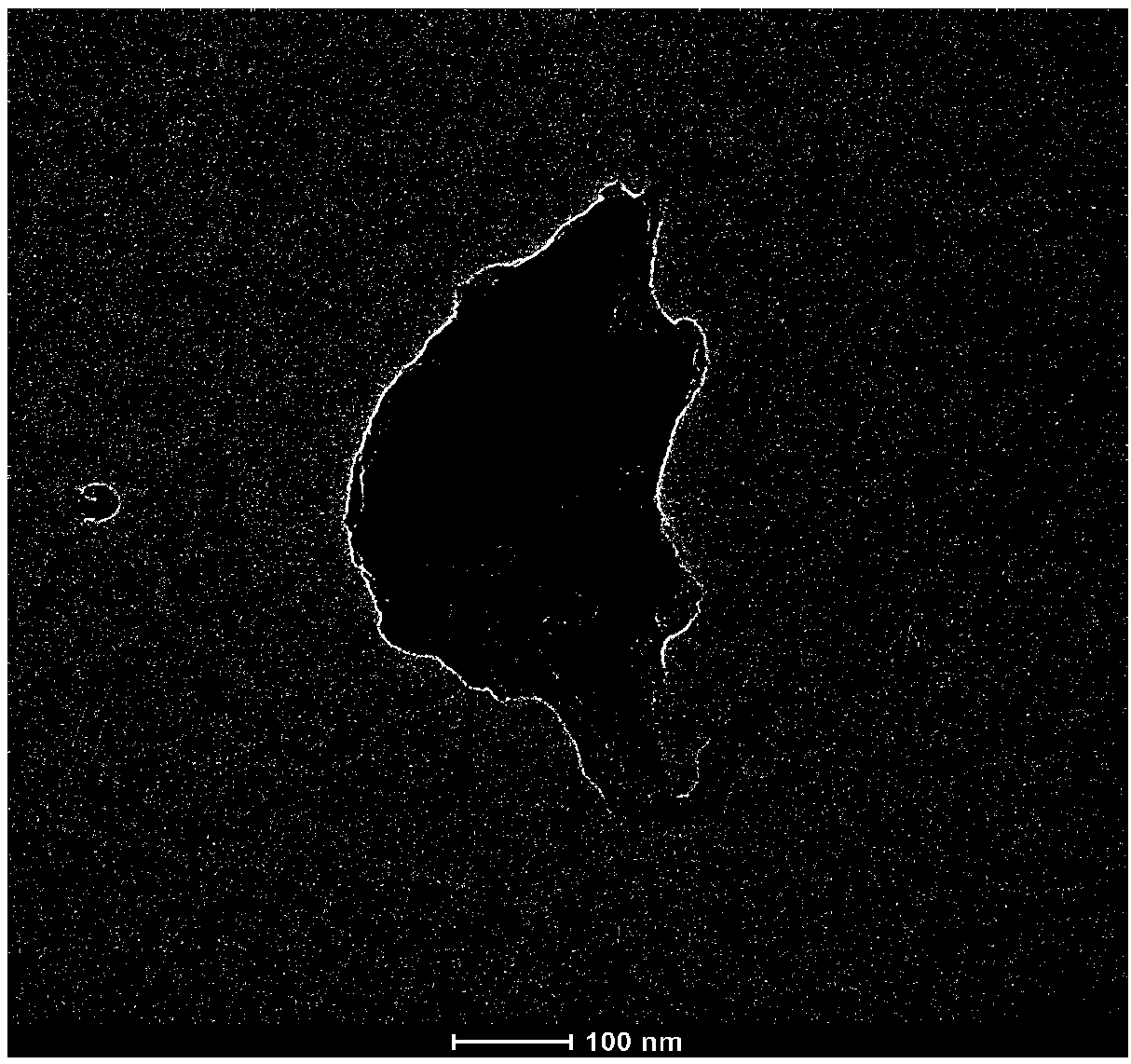

[0048] (5) Weigh 5 mg of nitrogen-doped bacterial cellulose from step (4) and disperse it in a mixed solution of 1 ml of deionized water and ethan...

Embodiment 2

[0054] (1) Weigh 10 mg of clean bacterial cellulose and place it in a beaker on average, add 80 milliliters, 1 mole / liter of hydrochloric acid solution to completely immerse the bacterial cellulose, add 200 microliters of aniline while stirring, and continue to react for 24 hours;

[0055] (2) in the beaker of step (1), add 80 milliliters of 1 mol / liter hydrochloric acid solutions that are dissolved with 3 grams of ammonium persulfate dropwise, continue to stir for 5 hours;

[0056] (3) the reaction product of step (2) washed the bacterial cellulose after the reaction repeatedly with deionized water and freeze-dried for 24 hours;

[0057] (4) calcining the bacterial cellulose obtained in step (3) for 2 hours under a nitrogen atmosphere of 800 degrees (heating rate 5 degrees / minute), to obtain nitrogen-doped bacterial cellulose;

[0058] (5) Weigh 5 mg of nitrogen-doped bacterial cellulose from step (4) and disperse it in a mixed solution of 1 ml of deionized water and ethanol ...

Embodiment 3

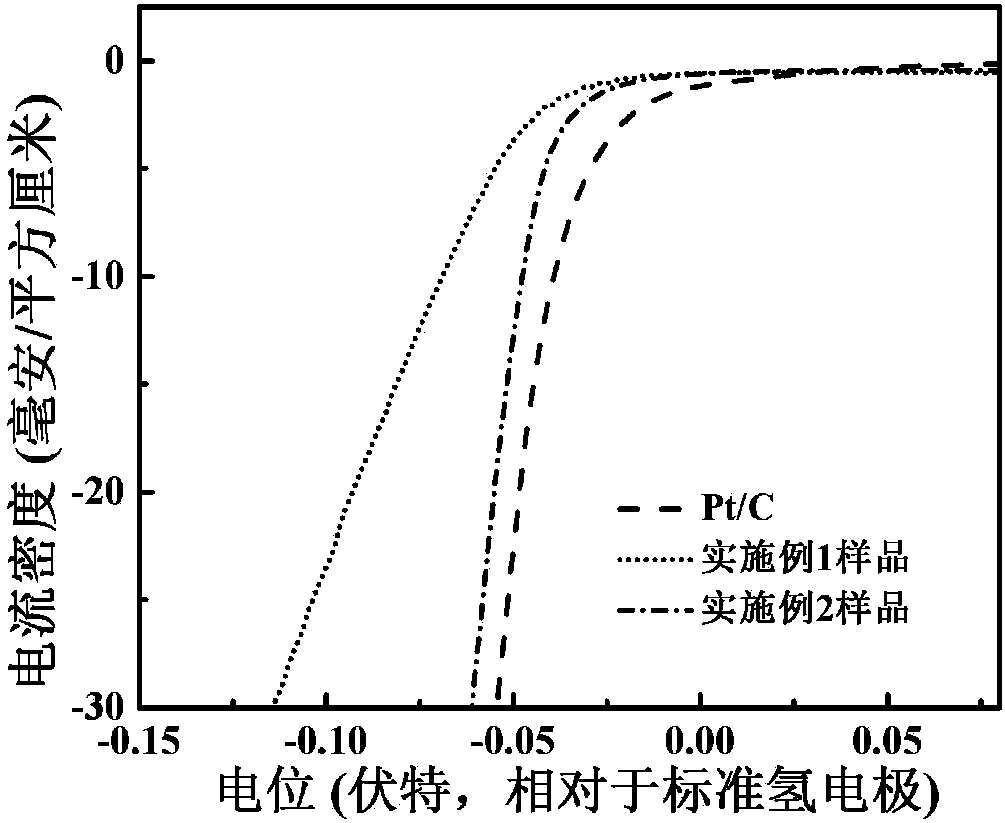

[0064] a) A 0.1 mol / L sulfuric acid solution was passed through nitrogen for 30 minutes and then added to the beaker. The glassy carbon electrode modified with the material was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. After connecting the three-electrode system, immerse in the sulfuric acid solution.

[0065] b) Select linear sweep voltammetry, set the start potential to -0.1V, end potential to -0.7V, and scan speed to 5mV s -1 , with a sensitivity of 10 -2 . The hydrogen evolution activity of platinum nanoparticle-supported nitrogen-doped bacterial cellulose electrode in electrolysis of water was investigated by linear sweep voltammetry.

[0066] c) Convert the potential relative to the saturated calomel electrode to that relative to the standard hydrogen electrode using the formula: E RHE =E SCE +0.059pH+0.242V, promptly get the polarization curve (as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com