A kind of composite bone cement, preparation method and application thereof and a kind of bone repair material

A technology for bone cement and bone repair, which is applied in the fields of composite bone cement, bone repair materials, and preparation. It can solve problems such as insufficient compressive strength, easy collapse, and incapable of load-bearing bone repair, so as to broaden the scope of use and improve collapse resistance. , Enhance the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a composite bone cement, which is prepared by mixing raw materials including 80% solid phase powder and 20% solidification liquid according to mass percentage, and the solid phase powder is composed of anhydrous calcium hydrogen phosphate: tetracalcium phosphate according to 30%: 70% mass percentage is uniformly mixed, and the solidified liquid is prepared by uniformly mixing citric acid: chitosan: hyaluronic acid: water according to 20%: 20%: 10%: 50% mass percentage.

[0044] This embodiment also provides a preparation method of the above-mentioned composite bone cement. Anhydrous calcium hydrogen phosphate: tetracalcium phosphate is mixed uniformly according to the mass percentage of 30%:70% to prepare a solid phase powder, and citric acid is added to deionized water to form Citric acid solution, then add chitosan and hyaluronic acid in the citric acid solution and mix uniformly to prepare a solidified solution, in the solidified solution, citri...

Embodiment 2

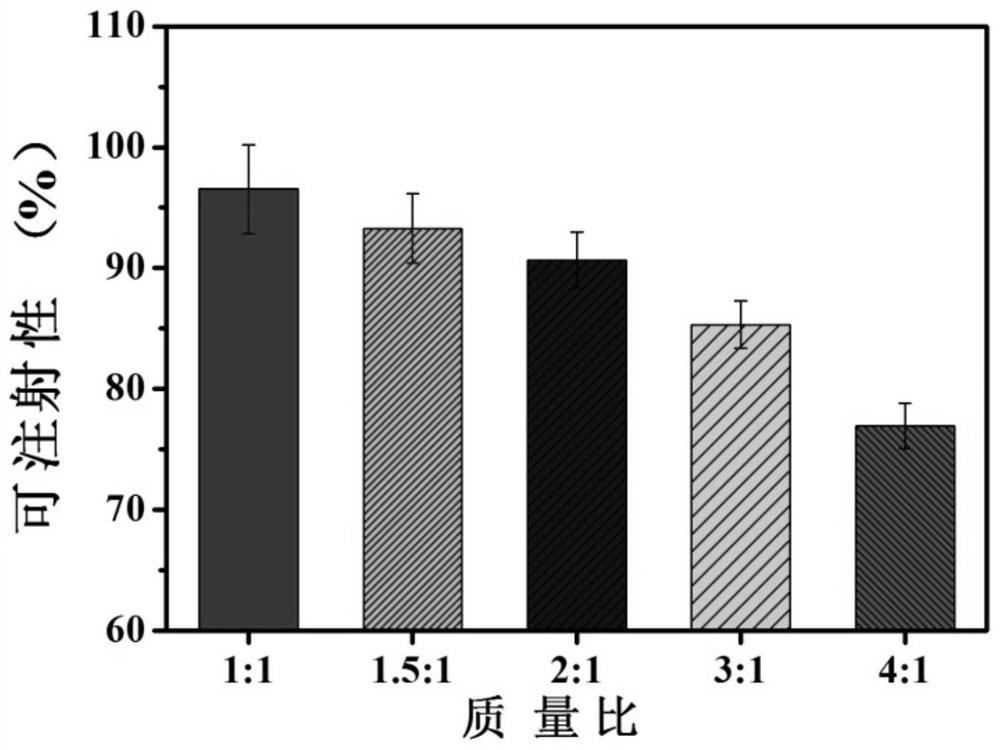

[0047] Take anhydrous calcium hydrogen phosphate: tetracalcium phosphate according to the mass percentage of 70%: 30%, mix uniformly to prepare solid phase powder, take citric acid and add deionized water to form a citric acid solution, and then add chitosan in the citric acid solution It is uniformly mixed with hyaluronic acid to prepare a solidified liquid, and the mass ratio of citric acid: chitosan: hyaluronic acid: water in the solidified liquid is 5%: 5%: 1%: 89%. At room temperature, the solid phase powder and the solidified liquid are respectively according to the mass percentages of 50%: 50%, 60%: 40%, 66.7%: 33.3%, 75%: 25% and 80%: 20% (that is, the mass ratios are respectively 1:1, 1.5:1, 2:1, 3:1 and 4:1) were mixed for 2 minutes to prepare five kinds of uncured composite bone cement.

[0048] Take the above five kinds of uncured composite bone cement, and use a medical syringe to characterize the injectability of the composite bone cement. The specific process is...

Embodiment 3

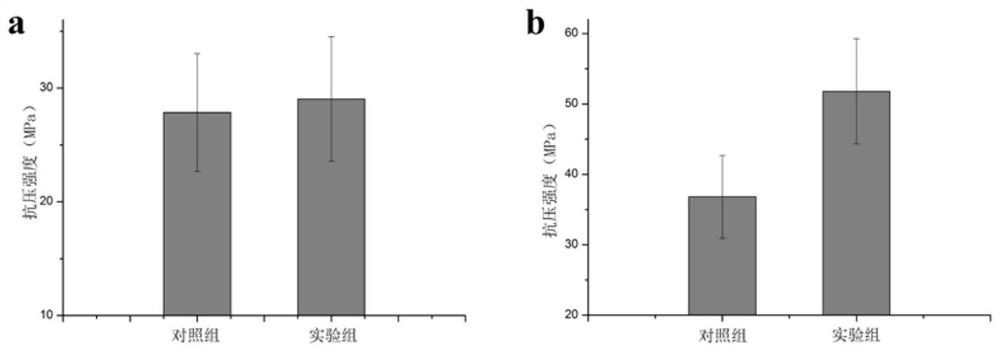

[0050] Take anhydrous calcium hydrogen phosphate: tetracalcium phosphate according to the mass percentage of 40%: 60% and mix evenly to prepare a solid phase powder, take acetic acid and add deionized water to form an acetic acid solution, and then add chitosan and hyaluronic acid to the acetic acid solution in turn The acids are evenly mixed to prepare a solidified liquid, in which the mass ratio of acetic acid: chitosan: hyaluronic acid: water is 15%: 15%: 5%: 65%. At room temperature, the solid phase powder and the solidification solution were mixed according to the mass percentage of 80%:20% for 1 minute respectively, and an uncured composite bone cement was prepared.

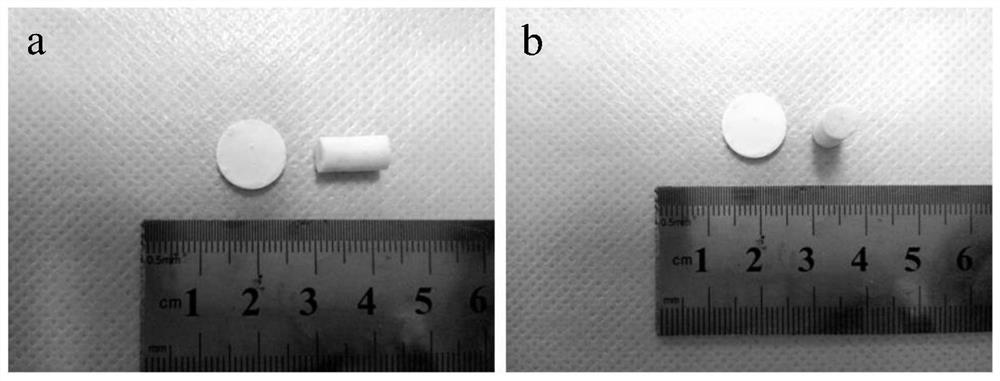

[0051] Experimental group: the above-mentioned uncured composite bone cement was filled into a mold with a diameter of 6 mm and a height of 12 mm, cured at 37 degrees Celsius for 24 hours, demolded and taken out to obtain a bone repair material.

[0052] Control group: take solid-phase powder and deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com