Lithium nickel cobalt manganate composite positive pole material and its preparation method and lithium battery

A composite cathode material, lithium nickel cobalt manganese oxide technology, applied in the direction of positive electrodes, battery electrodes, secondary batteries, etc., can solve the problems of battery capacity loss, inability to meet battery cycle and safety requirements, etc., to reduce residual lithium, improve Cycling performance and storage performance, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

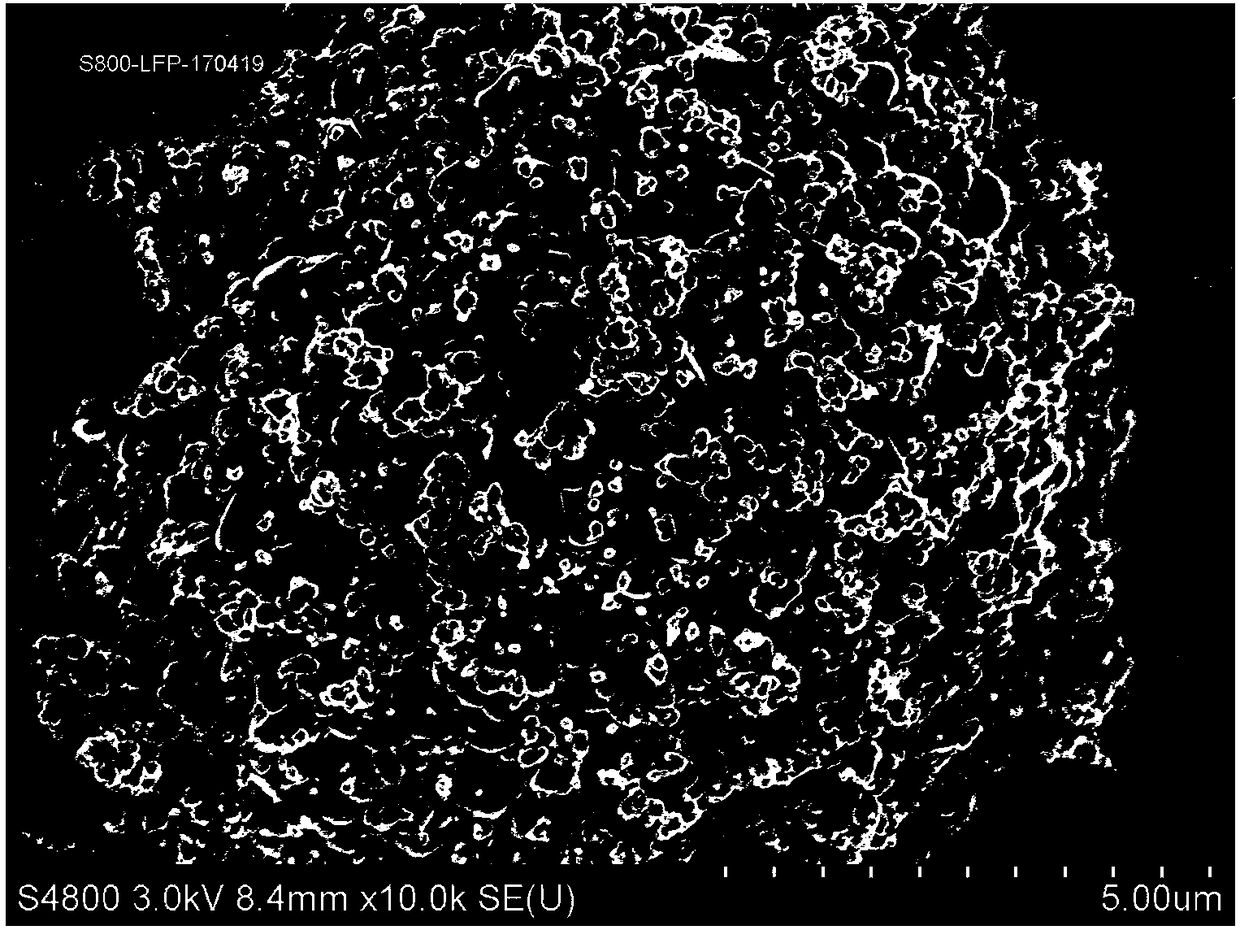

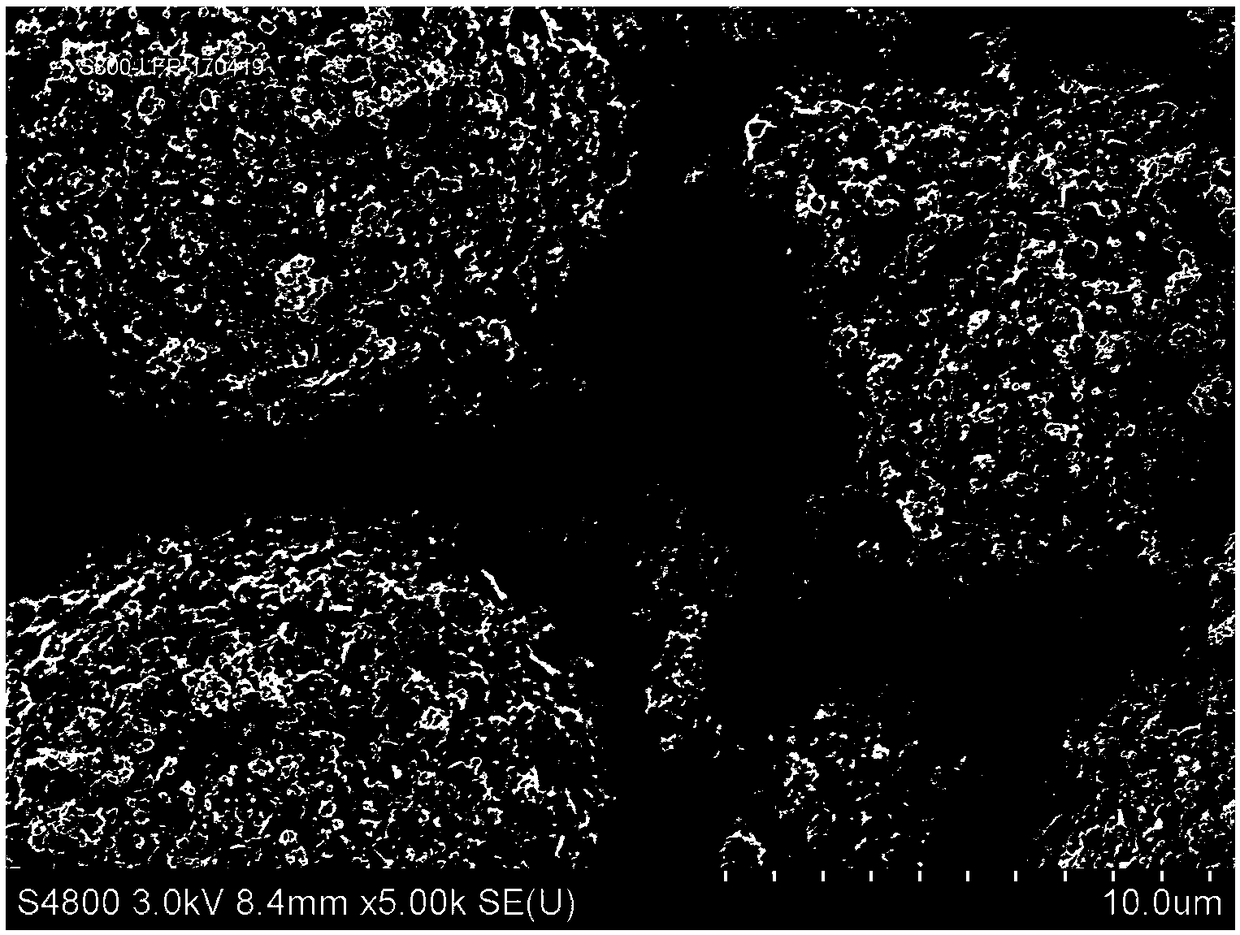

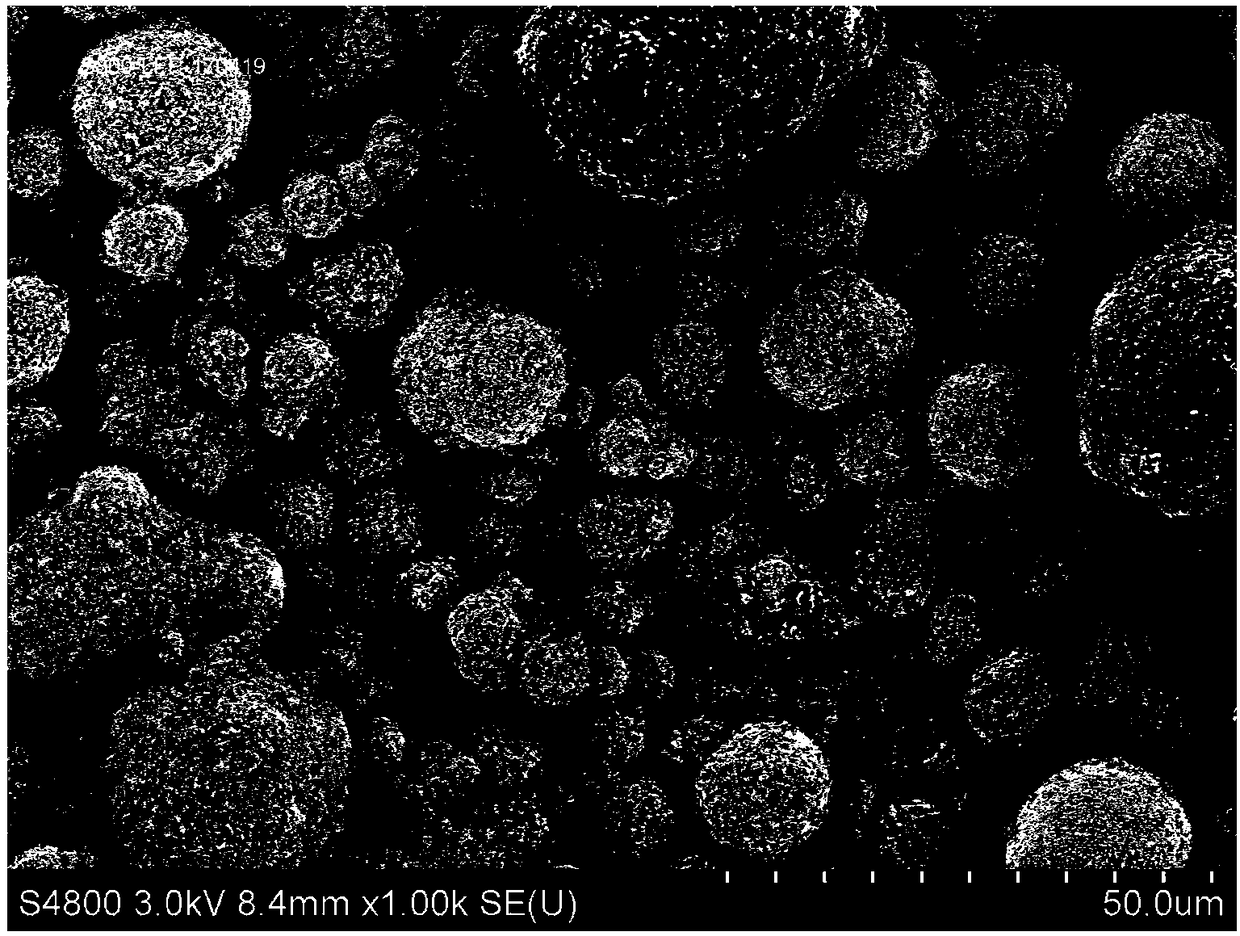

[0034] The nickel-cobalt-lithium-manganese-oxide composite positive electrode material of the present embodiment comprises nickel-cobalt-lithium-manganate particles and a lithium iron phosphate coating layer coated on the surface of the nickel-cobalt-lithium-manganese-oxide particles. The mass ratio of nickel cobalt lithium manganese oxide particles to lithium iron phosphate coating layer is 95:5. Among them, the nickel cobalt lithium manganese oxide particles are NCM811 materials, specifically LiNi 0.83 co 0.1 mn 0.07 o 2 Material. Nickel cobalt lithium manganese oxide particles are secondary particles of nickel cobalt lithium manganese oxide, composed of nickel cobalt lithium manganese oxide primary particles, the particle size of nickel cobalt lithium manganese oxide secondary particles is 10μm, The particle size is 300nm. The lithium iron phosphate coating layer is a nanometer lithium iron phosphate material. The lithium iron phosphate coating layer is composed of li...

Embodiment 2

[0041] The nickel-cobalt-lithium-manganese-oxide composite positive electrode material of the present embodiment comprises nickel-cobalt-lithium-manganate particles and a lithium iron phosphate coating layer coated on the surface of the nickel-cobalt-lithium-manganese-oxide particles. The mass ratio of nickel cobalt lithium manganese oxide particles to lithium iron phosphate coating layer is 97:3. Among them, the nickel cobalt lithium manganese oxide particles are NCM811 materials, specifically LiNi 0.83 co 0.1 mn 0.07 o 2 Material. Nickel cobalt lithium manganese oxide particles are secondary particles of nickel cobalt lithium manganese oxide, composed of nickel cobalt lithium manganese oxide primary particles, the particle size of nickel cobalt lithium manganese oxide secondary particles is 10μm, The particle size is 500nm. The lithium iron phosphate coating layer is a nanometer lithium iron phosphate material. The lithium iron phosphate coating layer is composed of li...

Embodiment 3

[0048] The nickel-cobalt-lithium-manganese-oxide composite positive electrode material of the present embodiment comprises nickel-cobalt-lithium-manganate particles and a lithium iron phosphate coating layer coated on the surface of the nickel-cobalt-lithium-manganese-oxide particles. The mass ratio of nickel cobalt lithium manganese oxide particles to lithium iron phosphate coating layer is 99:1. Among them, the nickel cobalt lithium manganese oxide particles are NCM811 materials, specifically LiNi 0.83 co 0.1 mn 0.07 o 2 Material. Nickel cobalt lithium manganese oxide particles are secondary particles of nickel cobalt lithium manganese oxide, composed of nickel cobalt lithium manganese oxide primary particles, the particle size of nickel cobalt lithium manganese oxide secondary particles is 10μm, The particle size is 500nm. The lithium iron phosphate coating layer is a nanometer lithium iron phosphate material. The lithium iron phosphate coating layer is composed of li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com