Fluorescent ceramic applied to LED and preparation method of fluorescent ceramic

A fluorescent ceramic, blue light excitation technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of phosphor luminescent epoxy resin or silica gel aging, reduced device performance and service life, poor thermal conductivity, etc., to avoid environmental problems. Use of oxygen resin or silica gel, make up for light loss, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention also provides a method for preparing fluorescent ceramics applied to LEDs. The preparation method comprises the following steps:

[0054] S1, providing raw materials and performing ball milling, drying, and burning in sequence to obtain powder;

[0055] S2, performing grinding, molding, and cold isostatic pressing on the powder in sequence to obtain a prefabricated ceramic prefabricated ceramic;

[0056] S3, in an oxygen atmosphere, sintering the green body to obtain prefabricated ceramics;

[0057] S4, annealing the prefabricated ceramics in a reducing atmosphere to obtain prefabricated fluorescent ceramics.

[0058] In step S1, according to (A 1-x B x ) m-y C y (D 1-z E. z ) 8-m o 12 The stoichiometric ratio of the reaction raw materials was weighed. Commercially available micron or nanometer raw materials with a purity of more than 99% can be used without further processing of the raw materials, which can save costs and facilitate industriali...

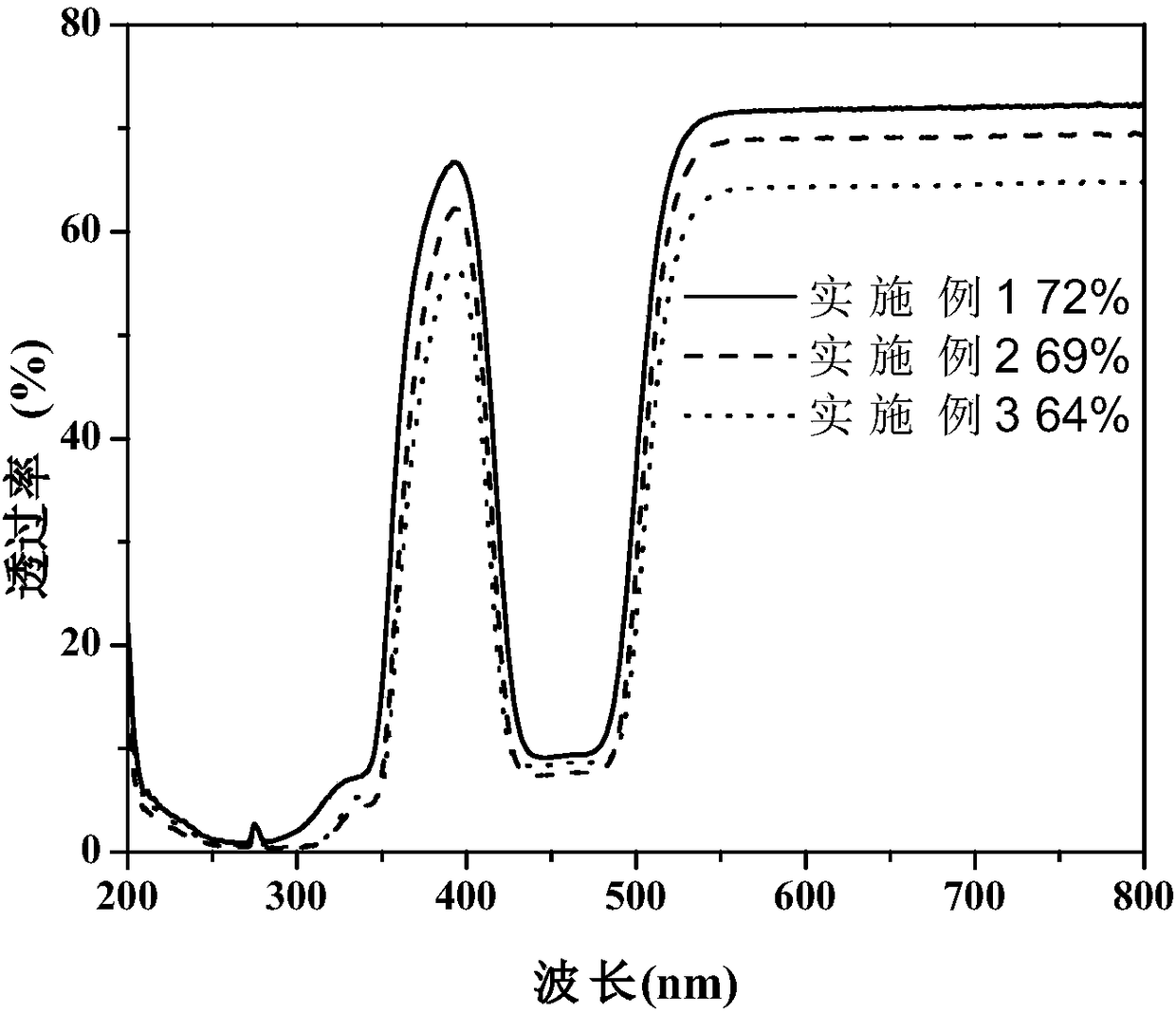

Embodiment 1

[0073] The general chemical formula of this fluorescent ceramic is (Y 0.5 Gd 0.5 ) 2.9999 Ce 0.0001 (Ga 0.6 al 0.4 ) 5 o 12 , that is, x=0, y=0.0001, z=0.4, m=3, A is Y and Gd, C is Ce, D is Ga, and E is Al.

[0074] The preparation method of this fluorescent ceramic is as follows:

[0075] Commercially available high-purity Y 2 o 3 、Gd 2 o 3 、Ce 2 (CO 3 ) 3 , Ga 2 o 3 、Al 2 o 3 As the starting material, accurately weigh the quality of each oxide or carbonate according to the above formula. Use 5mm polytetrafluoroethylene balls as the grinding balls for the weighed reaction raw materials, and use absolute ethanol as the ball milling medium. The balls and the medium were put into a polytetrafluoroethylene ball mill jar, and ball milled in a planetary ball mill at a speed of 300 rad / min for 12 hours to obtain a slurry. After the slurry was dried at 70°C for 12h in a blast drying oven, it was fired at 600°C for 2h to obtain a powder.

[0076] The powder was g...

Embodiment 2

[0080] The general chemical formula of this fluorescent ceramic is (Y 0.5 Gd 0.5 ) 2.99 Ce 0.01 (Ga 0.6 sc 0.4 ) 5 o 12 , that is, x=0, y=0.01, z=0.4, m=3, A is Y and Gd, C is Ce, D is Ga, and E is Sc.

[0081] The preparation method of this fluorescent ceramic is as follows:

[0082] Commercially available high-purity Y 2 o 3 、Gd 2 o 3 、Ce 2 (CO 3 ) 3 , Ga 2 o 3 、Sc 2 o 3 As the starting material, accurately weigh the quality of each oxide or carbonate according to the above formula. Use 5mm polytetrafluoroethylene balls as the grinding balls for the weighed reaction raw materials, and use absolute ethanol as the ball milling medium. The balls and the medium were put into a polytetrafluoroethylene ball mill jar, and ball milled in a planetary ball mill at a speed of 300 rad / min for 12 hours to obtain a slurry. After the slurry was dried at 70°C for 12h in a blast drying oven, it was fired at 900°C for 2h to obtain a powder.

[0083] The powder was ground in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com