Solvent-free polyurethane self-leveling floor topcoat and preparation process thereof

A solvent-free polyurethane and solvent-free technology, applied in the field of coatings, can solve the problems of difficult drying, easy discoloration, chalking, and limiting the use range of floors, and achieve excellent drying performance, eliminate surface bubbles, and improve the effect of anti-settling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

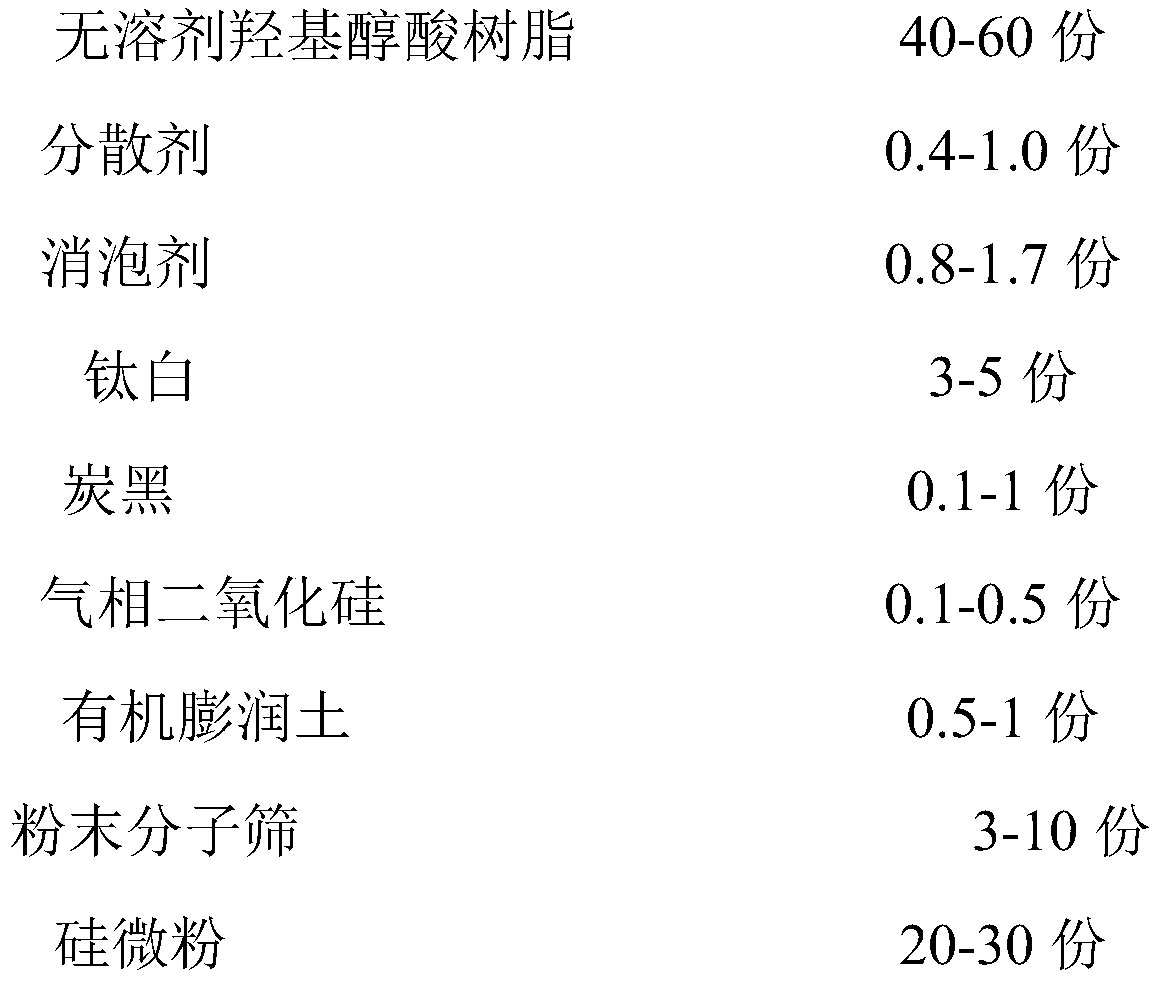

[0040] The weight composition of solvent-free hydroxy alkyd resin raw materials is shown in the following table:

[0041]

[0042] The solvent-free hydroxy alkyd resin of embodiment 1-3 is prepared by the following steps:

[0043] Step a: Add castor oil into the reaction kettle, stir and heat up to 200°C, stop stirring and add catalyst, when stirring continues to heat up to 210°C, stop stirring and add glycerin, start stirring and heat up to 225±2°C, keep the temperature for 1h;

[0044] Step b: Cool down to 160°C, stop stirring, add adipic acid and petroleum xylene, and fill the water separator with petroleum xylene;

[0045] Step c: raise the temperature to 225±2°C, measure the acid value after 3 hours of heat preservation, and vacuumize when the acid value drops below 1;

[0046] Step d: vacuumize and cool down when the solid content reaches 99% or more, cool down to 60°C and filter with 120-mesh silk cloth to obtain a solvent-free hydroxy alkyd resin.

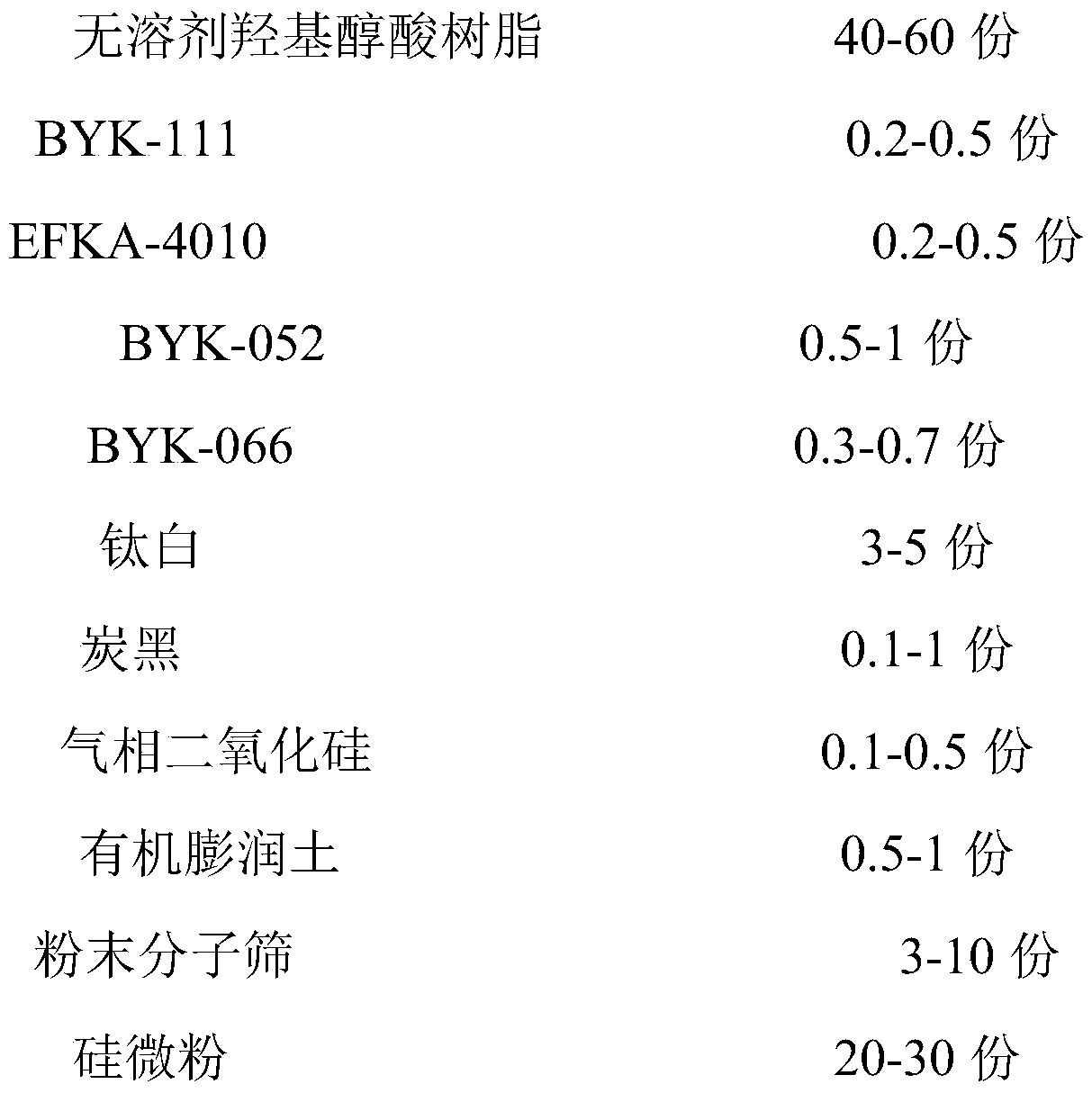

[0047] The sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com