Absorbable iron-based instrument

An iron-based and device technology, applied in the field of absorbable iron-based devices, can solve problems such as corrosion of iron-based devices and affect the structural integrity and mechanical properties of iron-based devices, to accelerate corrosion, reduce the possibility of adverse reactions, and avoid cell damage. toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

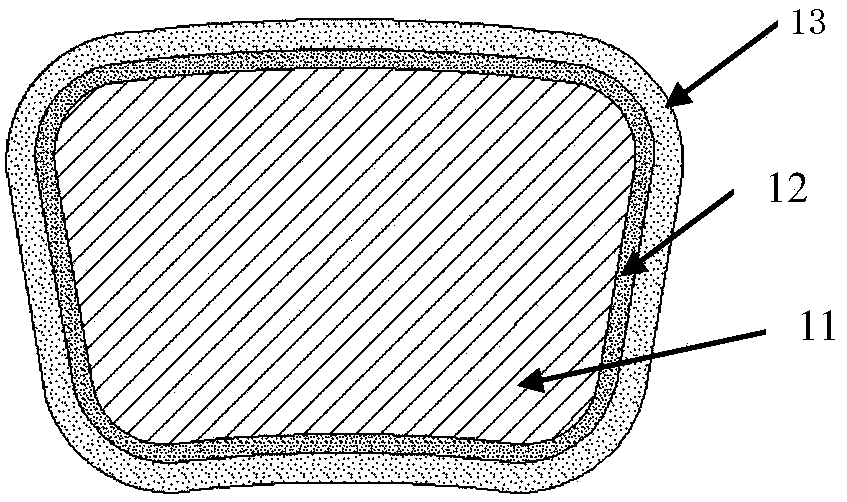

[0074] The absorbable iron-based stent provided in Example 1 is composed of a plurality of stent rods. See figure 1 , each stent rod includes an iron-based substrate 11 , a zinc-containing protective body 12 completely covering the iron-based substrate 11 , and a degradable polyester coating 13 completely covering the zinc-containing protective body 12 . The iron-based substrate 11 is made of an iron-based alloy with a carbon content of 1.19%. The zinc-containing protective body 12 is a single zinc coating. The degradable polyester coating 13 is poly-racemic lactic acid with a mass fraction of low molecular weight fractions below 10,000 of 2% and a mass fraction of residual monomers of 1.6%.

[0075] The manufacturing process of the absorbable iron-based stent provided in Example 1 is as follows:

[0076] On the surface of the iron-based stent with an original radial support force of 145kPa and a mass of 4.5mg, the vacuum evaporation method is used to uniformly plate zinc a...

Embodiment 2

[0081] On the surface of the iron-based stent with an original radial support force of 145kPa and a mass of 4.5mg, the vacuum evaporation method is used to uniformly plate zinc as a zinc-containing protective body, so that the zinc element completely covers the surface of the iron-based stent, and the mass of the zinc element The mass ratio to the iron-based support is 1:200 to obtain a galvanized iron-based support. The polyracemic lactic acid is separated and purified by GPC method, and the mass fraction of the low molecular weight part with a molecular weight of less than 10,000 is 2%, and the mass fraction of the residual monomer is 1.6%. The obtained polyracemic lactic acid was dissolved in ethyl acetate to obtain a coating solution. Spray the coating solution onto the surface of the galvanized iron-based stent, and make the ratio of the mass of polyracemic lactic acid to the mass of the iron-based stent be 1:10, dry to remove ethyl acetate, crimp on the crimping device a...

Embodiment 3

[0084] On the surface of the iron-based stent with an original radial support force of 145kPa and a mass of 4.5mg, the vacuum evaporation method is used to uniformly plate zinc as a zinc-containing protective body, so that the zinc element completely covers the surface of the iron-based stent, and the mass of the zinc element The mass ratio to the iron-based support is 1:20 to obtain a galvanized iron-based support. The polyracemic lactic acid is separated and purified by GPC method, and the mass fraction of the low molecular weight part with a molecular weight of less than 10,000 is 2%, and the mass fraction of the residual monomer is 1.6%. The obtained polyracemic lactic acid was dissolved in ethyl acetate to obtain a coating solution. Spray the coating solution onto the surface of the galvanized iron-based bracket, and make the ratio of the mass of polylactic acid to the mass of the iron-based bracket 1:10, dry to remove ethyl acetate, press on the crimping equipment and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com