High-efficiency low-impedance haze-resistant ventilation window gauze and preparation method thereof

A ventilation window and anti-smog technology, which is applied in separation methods, chemical instruments and methods, insect prevention, etc., can solve problems such as difficult cleaning, poor lighting of windows, single anti-smog, etc., achieve fresh indoor air, simple preparation process, and simple structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

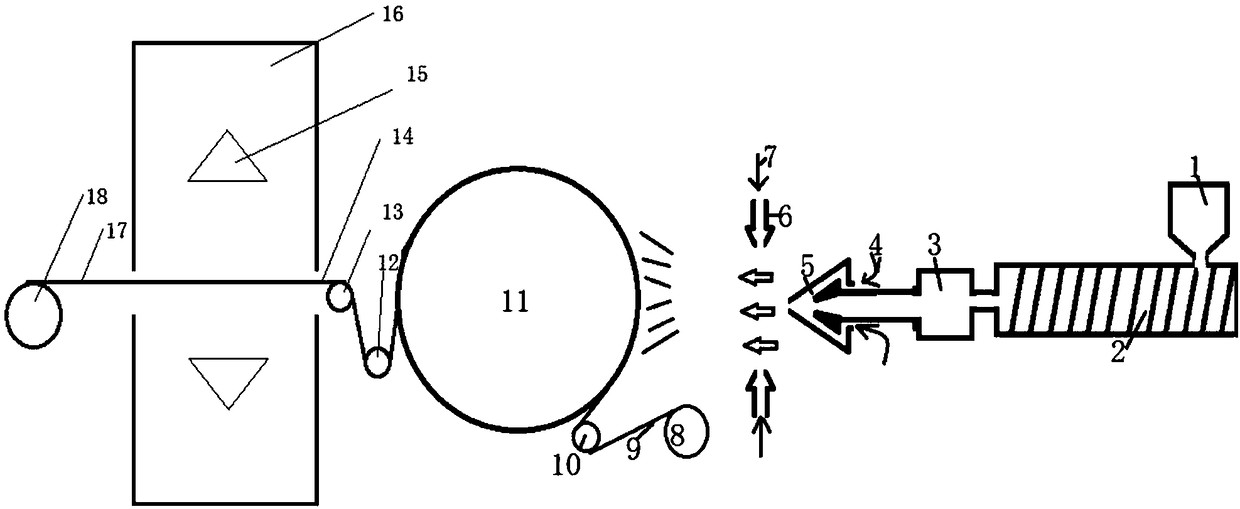

Image

Examples

example 1

[0035] This embodiment provides a high-efficiency, low-resistance haze-proof ventilating window screen and a preparation method thereof, characterized in that the preparation method of the high-efficiency, low-resistance haze-proof ventilating window screen comprises the following steps:

[0036] 1) Mix 60 parts of PTFE dispersion resin, 40 parts of liquid additive, 20 parts of liquid lubricant, 0.1 part of negative ion powder, 1 part of flame retardant, 1 part of pore-forming agent, 1-3 parts of anti-ultraviolet agent, and 1-3 parts of antioxidant 3 parts, 0.1 part of surfactant, uniformly mixed and allowed to stand at a temperature of 80°C to 90°C for 4 to 8 hours, the mixture is made into thin sheets by calendering, modified by degreasing, stretched and shaped, cooled and solidified to obtain PTFE Microporous membrane;

[0037] 2) 20 parts of polypropylene, 1 part of waxy short-chain tetrafluoroethylene telomer, perfluorinated compound C x f (2x+2) 1 part (x=30-35) and 1 ...

example 2

[0054] This embodiment provides a high-efficiency, low-resistance haze-proof ventilating window screen and a preparation method thereof, characterized in that the preparation method of the high-efficiency, low-resistance haze-proof ventilating window screen comprises the following steps:

[0055] 1) 90 parts of PTFE dispersion resin, 10 parts of liquid additives, 30 parts of liquid lubricant, 0.5 parts of negative ion powder, 3 parts of flame retardant, 3 parts of pore-forming agent, 3 parts of anti-ultraviolet agent, 3 parts of antioxidant, the surface 0.5 parts of active agent, uniformly mixed and allowed to stand at 90°C for 8 hours, the mixture was made into thin slices by calendering, modified by degreasing, stretched and shaped, cooled and solidified to obtain a PTFE microporous membrane;

[0056] 2) 20 parts of polypropylene, 2 parts of waxy short-chain tetrafluoroethylene telomer, perfluorinated compound C x f (2x+2) 2 parts (x=30-35) and 2 parts of triazine compound ...

example 3

[0073] This embodiment provides a high-efficiency, low-resistance haze-proof ventilating window screen and a preparation method thereof, characterized in that the preparation method of the high-efficiency, low-resistance haze-proof ventilating window screen comprises the following steps:

[0074] 1) 70 parts of PTFE dispersion resin, 20 parts of liquid additives, 25 parts of liquid lubricant, 0.3 parts of negative ion powder, 2 parts of flame retardant, 3 parts of pore-forming agent, 3 parts of anti-ultraviolet agent, 2 parts of antioxidant, surface 0.2 parts of active agent, uniformly mixed and allowed to stand at 85°C for 6 hours, the mixture was made into thin sheets by calendering, modified by degreasing, stretched and shaped, cooled and solidified to obtain a PTFE microporous membrane;

[0075] 2) 20 parts of polypropylene, 3 parts of waxy short-chain tetrafluoroethylene telomer, perfluorinated compound C x f (2x+2) 3 parts (x=30-35) and 3 parts of triazine compound are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com