High-strength heat-resistant aluminum alloy suitable for large-scale complex structure castings and its preparation process

A preparation process and aluminum alloy technology, applied in the field of cast aluminum alloy materials and its preparation, high-strength heat-resistant cast aluminum alloy and its preparation, to achieve the effects of improving thermal crack resistance, excellent room temperature and high temperature mechanical properties, and solving room temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

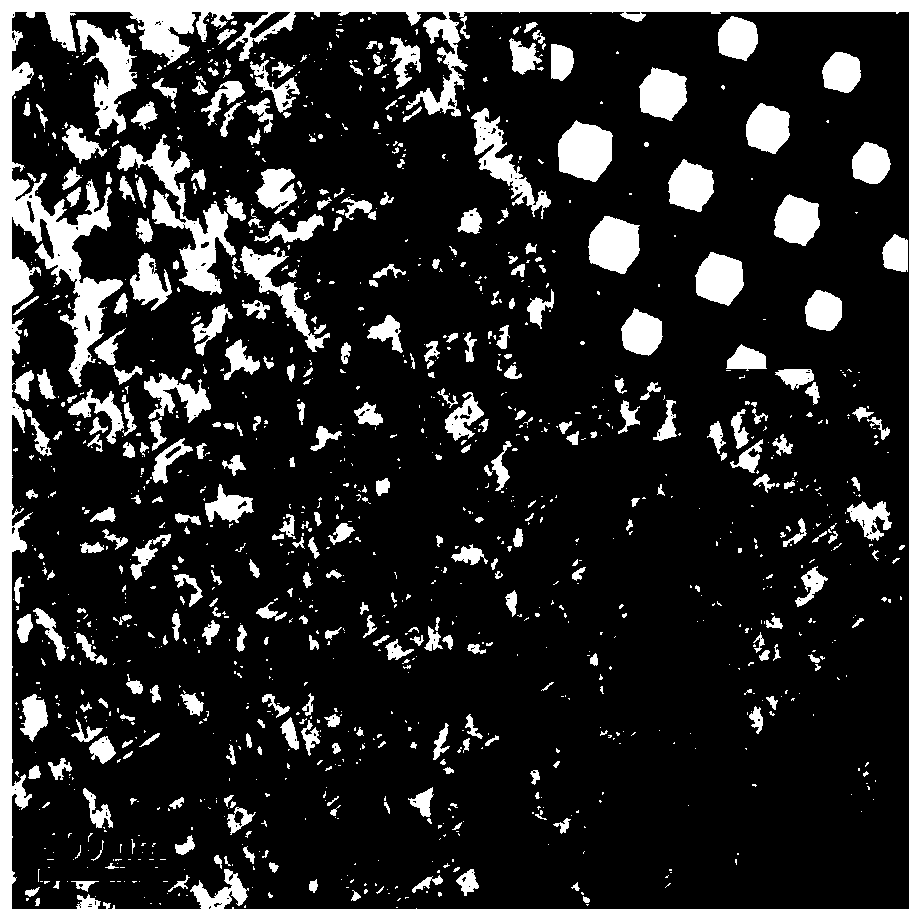

Image

Examples

Embodiment 1-1

[0036] The alloy composition is: 7.70% Cu, 1.22% Ag, 0.22% Mg, 0.20% Mn, 0.22% V, 0.05% Ti, 0.02% Fe, 0.03% Si, Cu / Mg=35, the balance is Al, and each group The sum of the points is 100%.

[0037] The smelting and casting process of the alloy follows the following steps: (1) According to the above formula, configure 3kg of the cast aluminum alloy material, wherein Al, Ag, and Mg are pure metals, Fe, Si are impurity elements, and the remaining elements are an intermediate alloy of aluminum, Clean the surface of the above metal, free from dust and oil, wrap the pure Mg tightly with aluminum foil, and then bake it at 150-200°C for 1-2h; (2) first melt the pure Al in a melting furnace at 760°C, and then add Pure Ag and Al-Cu, Al-Mn, Al-V intermediate alloys, after they are all melted, pass high-purity argon to degas the melt for 25 minutes, control the temperature of the melt at 735°C after removing slag, and use a clock Press the Mg into the melt under the hood, stir the melt slo...

Embodiment 1-2

[0040] The alloy composition is: 6.61% Cu, 0.60% Ag, 0.11% Mg, 0.50% Mn, 0.10% V, 0.15% Ti, 0.04% Fe, 0.06% Si, Cu / Mg=60, the balance is Al, and each group The sum of the points is 100%.

[0041] The melting and casting process of the alloy is the same as in Example 1-1.

[0042] The test rod is firstly subjected to solution heat treatment at 525°C / 10h, and then to artificial aging heat treatment at 180°C / 4h (T6 state). The room temperature and high temperature tensile properties of the T6 state test bars are shown in Table 1.

Embodiment 1-3

[0044] The alloy composition is: 6.40% Cu, 1.70% Ag, 0.38% Mg, 0.34% Mn, 0.35% V, 0.09% Ti, 0.06% Fe, 0.02% Si, Cu / Mg=16.8, the balance is Al, and each group The sum of the points is 100%.

[0045] The melting and casting process of the alloy is the same as in Example 1-1.

[0046] The test rod is firstly subjected to solution heat treatment at 530°C / 4h, and then to artificial aging heat treatment at 160°C / 14h (T6 state). The room temperature and high temperature tensile properties of the T6 state test bars are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com