Graphene-reinforced high-silicon aluminum-based composite material and preparation method thereof

A composite material and graphene technology, applied in the field of graphene applications, can solve the problems of reducing the tensile strength of materials, high production costs, and matrix splitting, and achieve good cutting performance, low thermal expansion coefficient, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

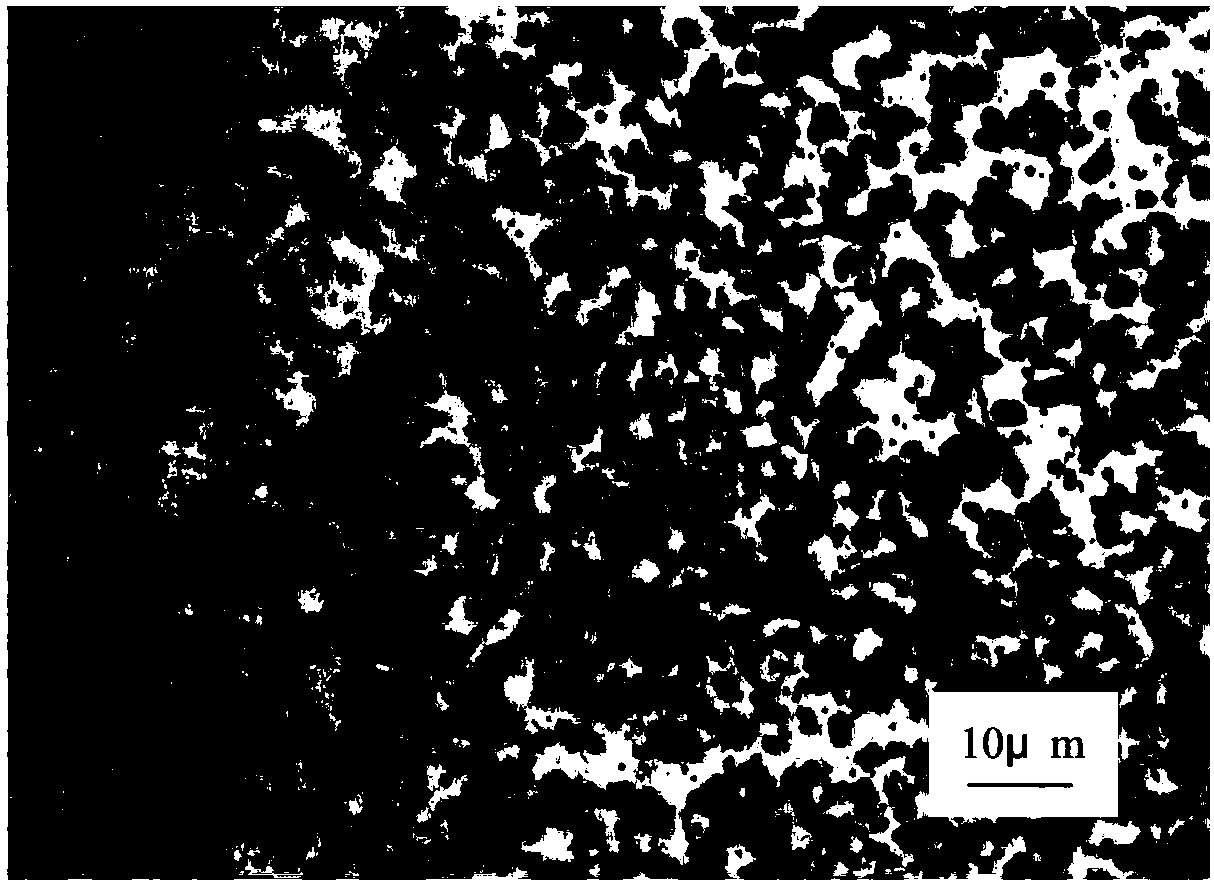

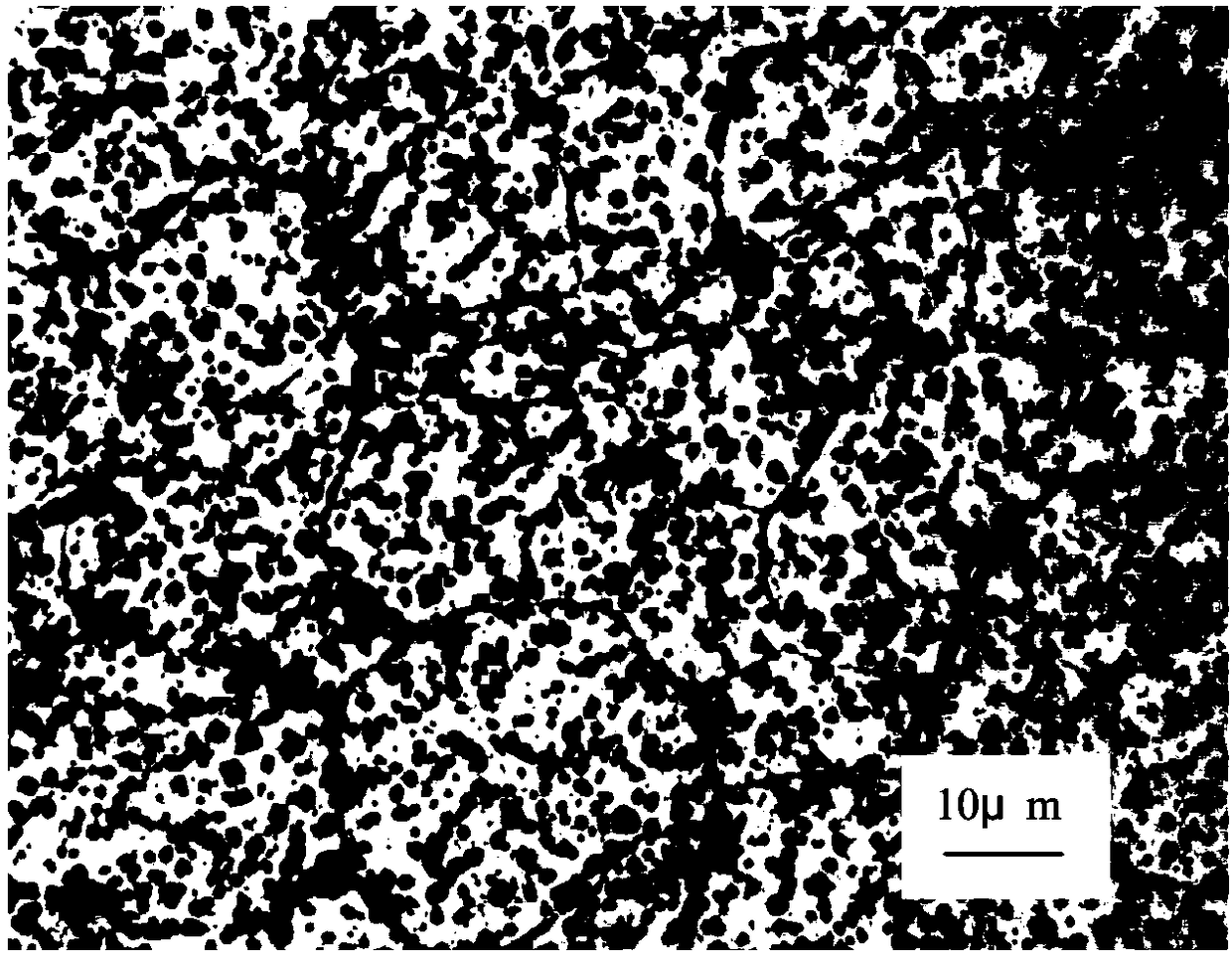

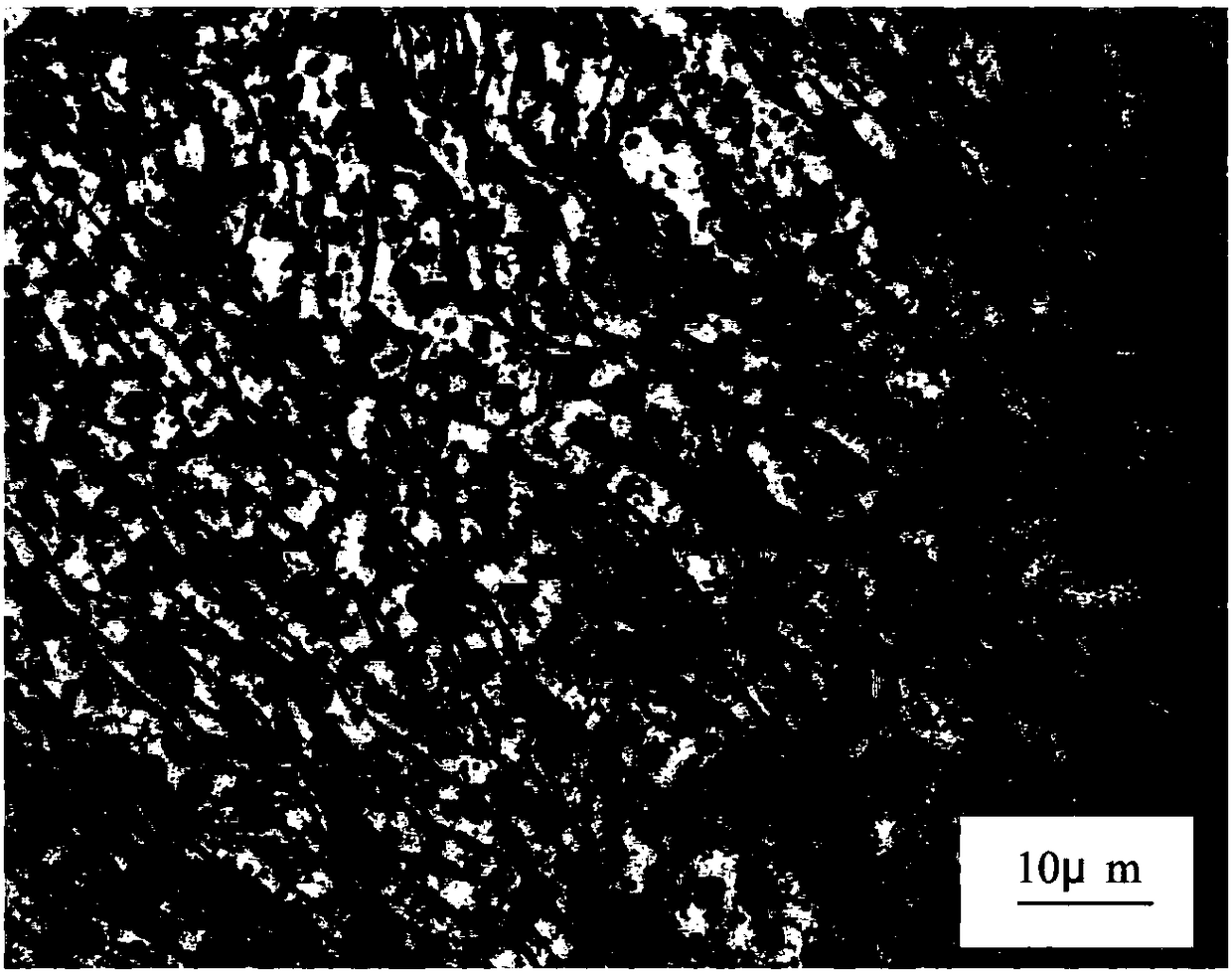

Image

Examples

Embodiment 1

[0041] A graphene-reinforced high-silicon-aluminum matrix composite material, containing components by mass percentage: silicon: 15.0%, copper: 4.0%, magnesium: 1.0%, titanium: 0.06%, boron: 0.03%, graphene: 0.5% , with aluminum as the balance.

[0042] The preparation method of the above-mentioned graphene-enhanced high-silicon-aluminum-based composite material specifically comprises the following steps:

[0043] Step 1, mixing ingredients:

[0044] The composition of the graphene-reinforced high-silicon-aluminum matrix composite is 15.0% silicon, 4.0% copper, 1.0% magnesium, 0.06% titanium, 0.03% boron, 0.5% graphene, and aluminum as the balance.

[0045] In the glove isolation box under the protection of argon, the 700-mesh various raw material powders are batched according to the above mass percentages and put into the mixing tank, and then the mixing tank is assembled on the ball mill, and then in the three-dimensional space motion mixing ball mill , mixed at a speed of...

Embodiment 2

[0053] A graphene-reinforced high-silicon-aluminum matrix composite material, containing components by mass percentage: silicon: 16.0%, copper: 3.5%, magnesium: 1.0%, titanium: 0.06%, boron: 0.03%, graphene: 0.3% , with aluminum as the balance.

[0054] The preparation method of the above-mentioned graphene-enhanced high-silicon-aluminum-based composite material specifically comprises the following steps:

[0055] Step 1, mixing ingredients:

[0056] The composition of the graphene-reinforced high-silicon-aluminum matrix composite is 16.0% silicon, 3.5% copper, 1.0% magnesium, 0.06% titanium, 0.03% boron, 0.3% graphene, and aluminum as the balance.

[0057] In the glove isolation box under the protection of argon, the 700-mesh various raw material powders are batched according to the above mass percentages and put into the mixing tank, and then the mixing tank is assembled on the ball mill, and then in the three-dimensional space motion mixing ball mill , mixed at a speed of...

Embodiment 3

[0065] A graphene-reinforced high-silicon-aluminum matrix composite material, containing components by mass percentage: silicon: 20.0%, copper: 2.0%, magnesium: 1.0%, titanium: 0.07%, boron: 0.04%, graphene: 0.6% , with aluminum as the balance.

[0066] The preparation method of the above-mentioned graphene-enhanced high-silicon-aluminum-based composite material specifically comprises the following steps:

[0067] Step 1, mixing ingredients:

[0068] The composition of the graphene-reinforced high-silicon-aluminum matrix composite is 20.0% silicon, 2.0% copper, 1.0% magnesium, 0.07% titanium, 0.04% boron, 0.6% graphene, and aluminum as the balance.

[0069] In the glove isolation box under the protection of argon, the 700-mesh various raw material powders are batched according to the above mass percentages and put into the mixing tank, and then the mixing tank is assembled on the ball mill, and then in the three-dimensional space motion mixing ball mill , mixed at a speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com