Electroslag remelting device and method for refining metal scraps

A technology of electroslag remelting and scrap metal, which is applied in the field of metal refining and electroslag remelting, to achieve the effect of large contact area, good refining effect and avoiding the increase of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

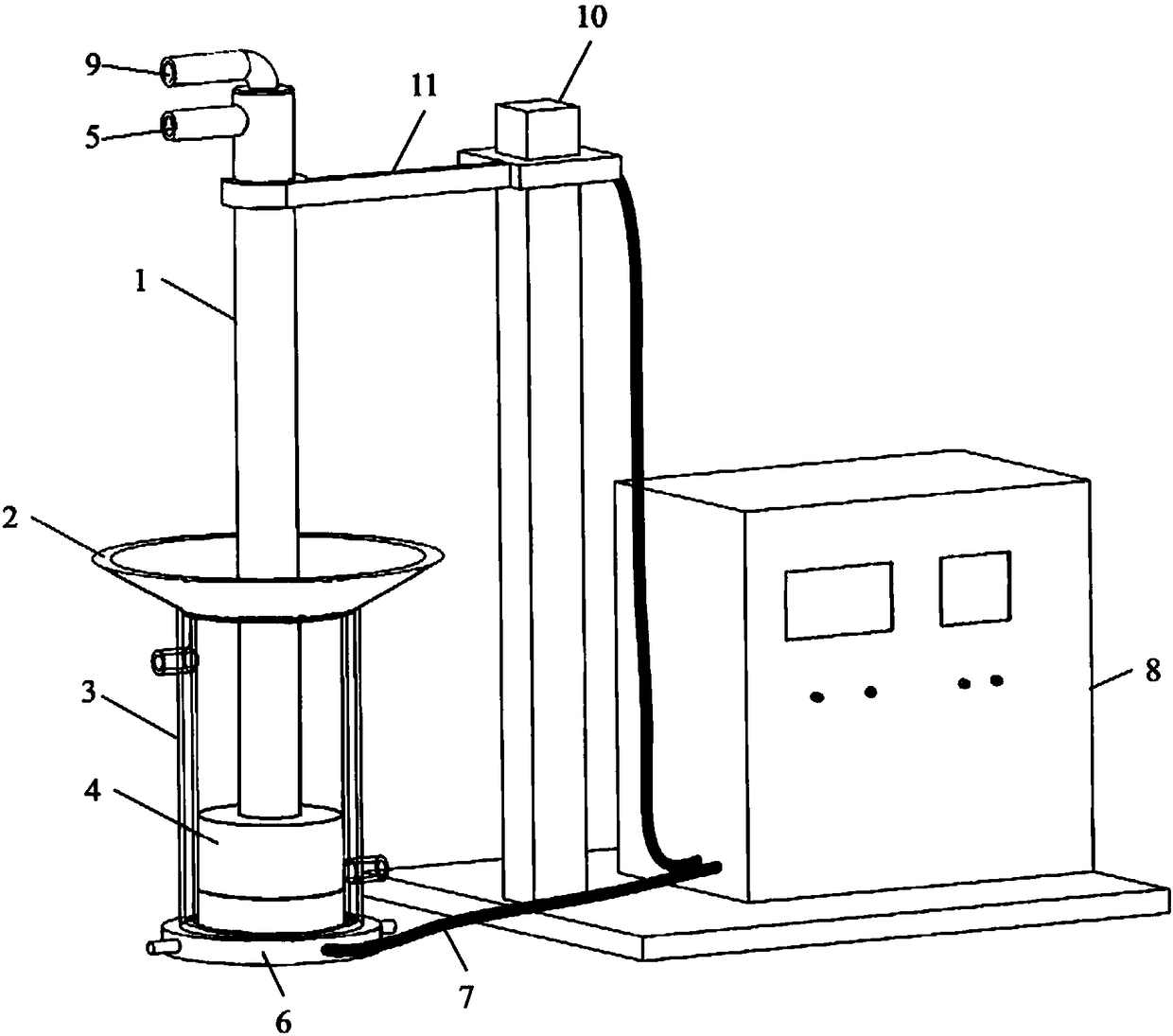

[0034] An electroslag remelting device for refining scrap metal scrap provided in this embodiment is as follows: figure 1 As shown, including water-cooled crystallizer 3, electrode, bottom water tank 6, power control cabinet 8, cable 7, column 10 and lifting cross arm 11, water-cooled crystallizer 3 is placed on bottom water tank 6, and the top of described water-cooled crystallizer 3 A vibrating feeder 2 for adding scrap metal scraps is provided, the electrode is a water-cooled electrode 1, and the water-cooled electrode 1 is installed on a lifting cross arm 11, and one end of the lifting cross arm is connected to a column and can be lifted up and down along the column The water-cooled electrode pair is inserted into the water-cooled crystallizer; the lifting cross arm 11 and the bottom water tank 6 are respectively connected to the power control cabinet 8 through cables 7 .

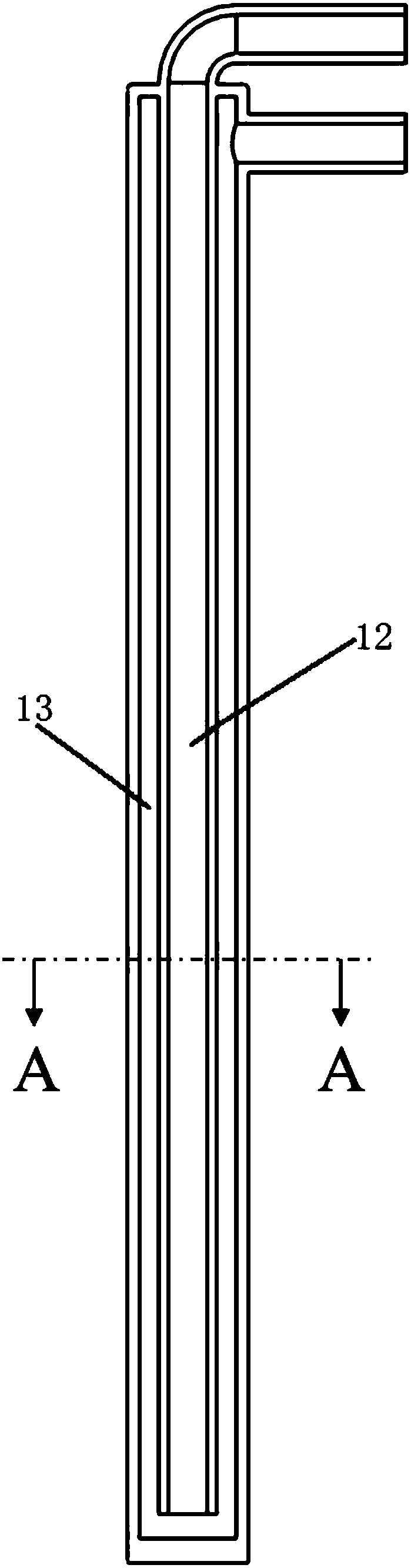

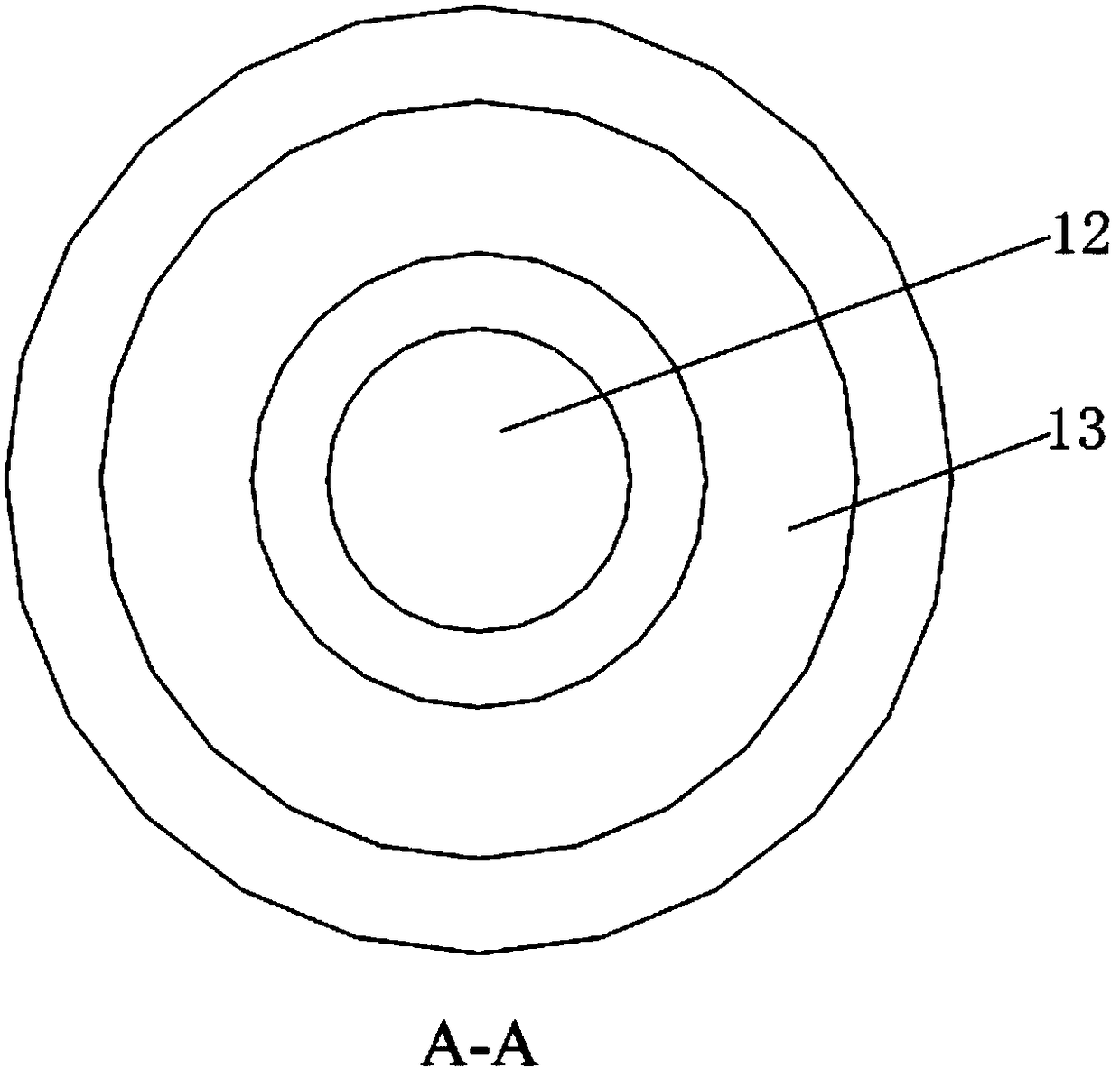

[0035] The water-cooled electrode 1 is a tube-in-tube structure made of red copper, and its structur...

Embodiment 2

[0049] In this example, electroslag remelting is carried out for high-priced recycled metal nickel scraps, and CaF 2 -Al 2 o 3 -CaO-MgO quaternary slag system, the proportion is CaF 2 Accounted for 55%, Al 2 o 3 30%, CaO 10%, MgO 5% (by weight), and the slag thickness is 350mm.

[0050] Step 1: Connect the water-cooled electrode to the cooling water pipe, and connect the cooling water. In this embodiment, the outer diameter of the water-cooled electrode is 210 mm, the wall thickness of the outer tube of the water-cooled electrode is 25 mm, and the wall thickness of the inner tube is 4 mm;

[0051] Step 2: When the temperature of the slag rises to 1600°C, pour the liquid pre-slag into the crystallizer. In this embodiment, the inner diameter of the crystallizer is 500mm;

[0052] Step 3: Lift the water-cooled electrode with a bridge crane, connect the upper end of the water-cooled electrode with the lifting cross arm, and then insert it into the liquid pre-melted slag in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com