Novel inorganic normal-temperature phase-change energy-storing material for facility agricultural temperature control as well as preparation method thereof

A technology of phase-change energy storage materials and facility agriculture, which is applied in the field of new inorganic room-temperature phase-change energy storage materials, can solve the problems of needing improvement and low latent heat of phase change, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

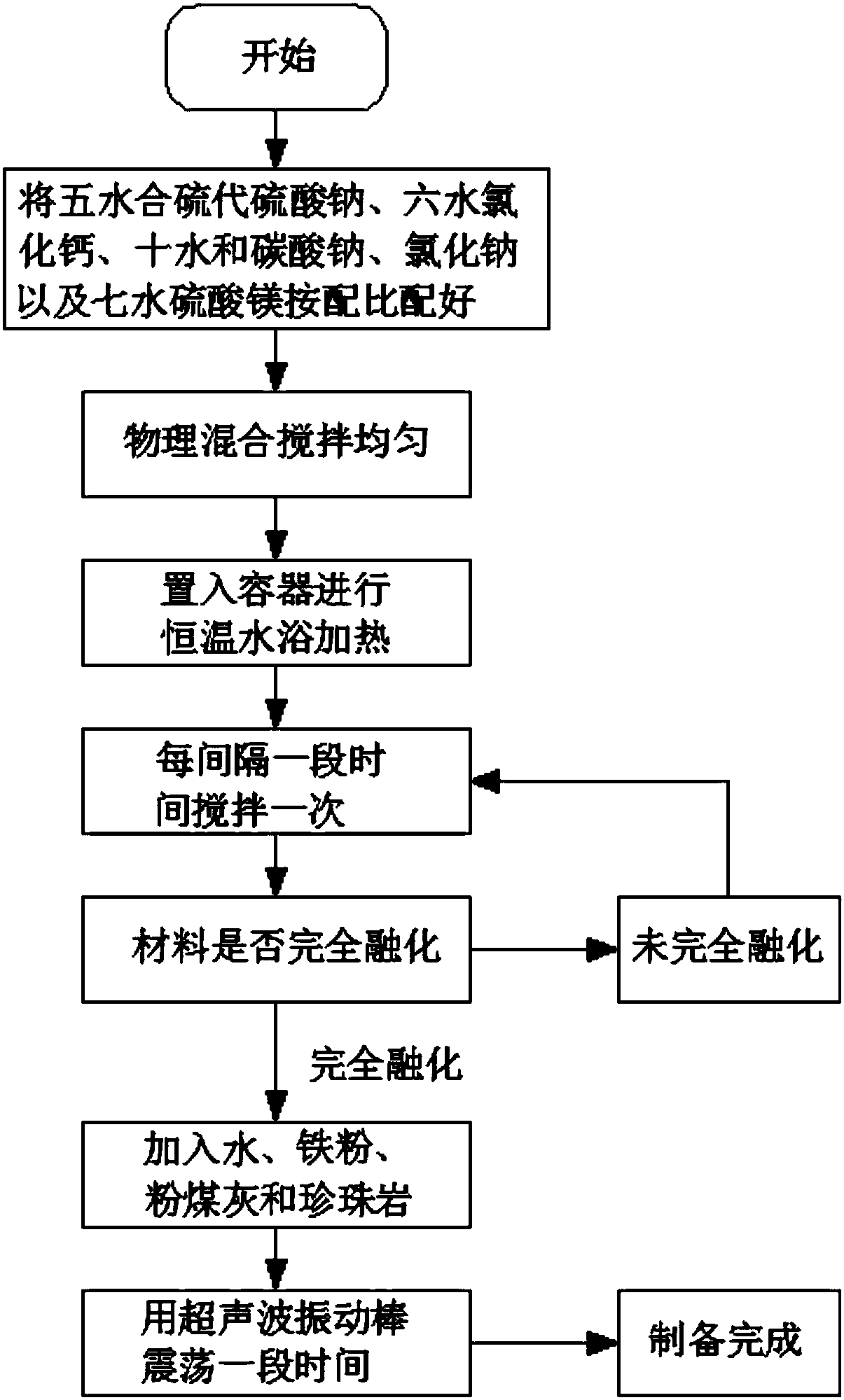

[0023] Such as figure 1 As shown, a method for preparing a novel inorganic normal-temperature phase-change energy storage material for temperature control in facility agriculture, the specific method is as follows:

[0024] (1) Get sodium thiosulfate pentahydrate, calcium chloride hexahydrate, decahydrate and sodium carbonate, sodium chloride and magnesium sulfate heptahydrate by proportioning and carry out physical mixing;

[0025] (2) After mixing evenly, put it in a container and heat it in a constant temperature water bath at 60°C. During the heating process, use a stirring rod to stir once every 12 minutes to facilitate the melting of the material until all the crystals are melted;

[0026] (3) Next, add water, iron powder, fly ash and perlite to the material prepared in step (2), and stir evenly, then put an ultrasonic vibrating rod into the material, and vibrate ultrasonically for 20 minutes.

[0027] In this embodiment, the phase change energy storage material include...

Embodiment 2

[0029] Such as figure 1 As shown, a method for preparing a novel inorganic normal-temperature phase-change energy storage material for temperature control in facility agriculture, the specific method is as follows:

[0030] (1) Get sodium thiosulfate pentahydrate, calcium chloride hexahydrate, decahydrate and sodium carbonate, sodium chloride and magnesium sulfate heptahydrate by proportioning and carry out physical mixing;

[0031] (2) After mixing evenly, put it in a container and heat it in a constant temperature water bath at 68°C. During the heating process, use a stirring rod to stir once every 10 minutes to facilitate the melting of the material until all the crystals are completely melted;

[0032] (3) Then add water, iron powder, fly ash and perlite to the material prepared in step (2), and stir evenly, then put an ultrasonic vibration rod into the material, and vibrate ultrasonically for 16 minutes.

[0033] In this embodiment, the phase change energy storage materi...

Embodiment 3

[0035] Such as figure 1 As shown, a method for preparing a novel inorganic normal-temperature phase-change energy storage material for temperature control in facility agriculture, the specific method is as follows:

[0036] (1) Get sodium thiosulfate pentahydrate, calcium chloride hexahydrate, decahydrate and sodium carbonate, sodium chloride and magnesium sulfate heptahydrate by proportioning and carry out physical mixing;

[0037] (2) After mixing evenly, put it in a container and heat it in a constant temperature water bath at 65°C. During the heating process, use a stirring rod to stir once every 9 minutes to facilitate the melting of the material until all the crystals are melted;

[0038] (3) Next, add water, iron powder, fly ash and perlite to the material prepared in step (2), and stir evenly, then put an ultrasonic vibrating rod into the material, and vibrate ultrasonically for 18 minutes.

[0039] In this embodiment, the phase change energy storage material includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com