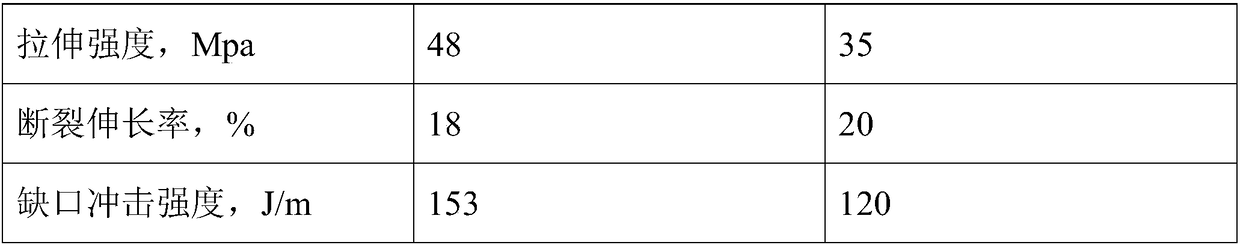

Preparation method of low-cost mobile phone charger casings

A mobile phone charger and shell preparation technology, which is applied in the field of chargers, can solve the problems of poor toughness and high cost, and achieve the effects of large cross-linking degree, high pressure bearing capacity and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A low-cost mobile phone charger shell preparation method, comprising the following steps: 60kg polychlorotrifluoroethylene, 30kg styrene-butadiene thermoplastic elastomer, 10kg nitrile rubber, 4kg disproportionated rosin, 6kg potassium titanate fiber, 14kg of medical stone powder, 6kg of diatomaceous earth, 16kg of hollow glass microspheres, stir evenly, add 1.5kg of tert-butyl hydroperoxide, 0.4kg of lanthanum oxide, 0.4kg of praseodymium oxide, 2kg of antioxidant 164, 1kg of antioxidant TPP to continue Stir evenly, form by hot pressing, and blast dry to obtain a mobile phone charger shell with low cost.

Embodiment 2

[0014] A low-cost mobile phone charger shell preparation method, comprising the following steps: 80kg polychlorotrifluoroethylene, 20kg styrene-butadiene thermoplastic elastomer, 20kg nitrile rubber, 2kg disproportionated rosin, 12kg potassium titanate fiber, Stir 8kg medical stone powder, 12kg diatomite, and 10kg hollow glass microspheres evenly, add 3kg tert-butyl hydroperoxide, 0.2kg lanthanum oxide, 1kg praseodymium oxide, 1kg antioxidant 164, 1.6kg antioxidant TPP and continue stirring Uniform, hot-pressed molding, blast drying to obtain a mobile phone charger shell with low cost.

Embodiment 3

[0016] A low-cost mobile phone charger shell preparation method, comprising the following steps: 65kg polychlorotrifluoroethylene, 28kg styrene-butadiene thermoplastic elastomer, 13kg nitrile rubber, 3.5kg disproportionated rosin, 8kg potassium titanate fiber , 12kg medical stone powder, 8kg diatomaceous earth, 14kg hollow glass microspheres and stir evenly, add 2kg tert-butyl hydroperoxide, 0.35kg lanthanum oxide, 0.6kg praseodymium oxide, 1.8kg antioxidant 164, 1.2kg antioxidant The TPP is continuously stirred evenly, hot-pressed, and blast-dried to obtain a mobile phone charger shell with low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com