Assembled compound pendulum slow-release jaw breaker

A slow-release jaw type and jaw crusher technology, which is applied in non-rotational vibration suppression, grain processing, etc., can solve the problems of hidden dangers in processing safety, low processing accuracy, easy loosening of anchor bolts, and failure of the whole machine to work. Achieve the effect of solving loose assembly bolts, low processing precision and low processing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

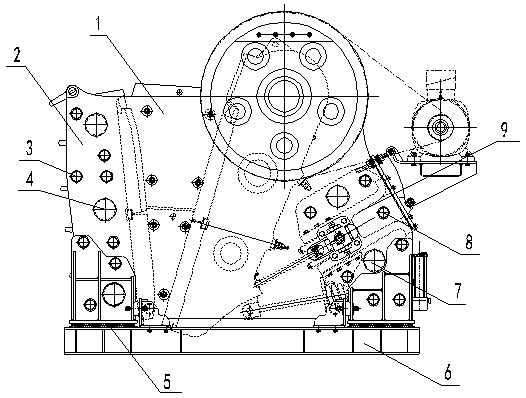

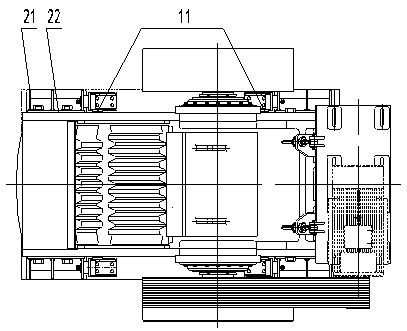

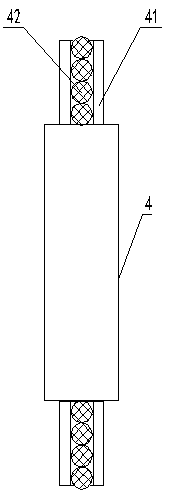

[0011] Embodiment 1: with reference to attached Figure 1-4 . An assembled compound pendulum slow-release jaw crusher, including a jaw crusher, in which the front stop body 2 and the rear stop body 9 are respectively positioned on the shock absorber bracket 6 through the shock absorber 5, and are located at the front The two side steel plates 1 between the baffle body 2 and the rear baffle body 9 are fastened with high-strength bolts. The two side bodies in the front bumper body 2 are high-strength low-alloy steel structures and are positioned by the front double-boss elastic cylindrical pins 4, and the front high-strength bolts 3 are penetrated and fixed. The side body has a concave-convex structure and is composed of a plurality of convex plates 21 and flat plates 22 , and the convex plates 21 and flat plates 22 are welded and formed. The rear stop body 9 is a split assembly structure and adopts the positioning of the rear double boss elastic cylindrical pin 7, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com