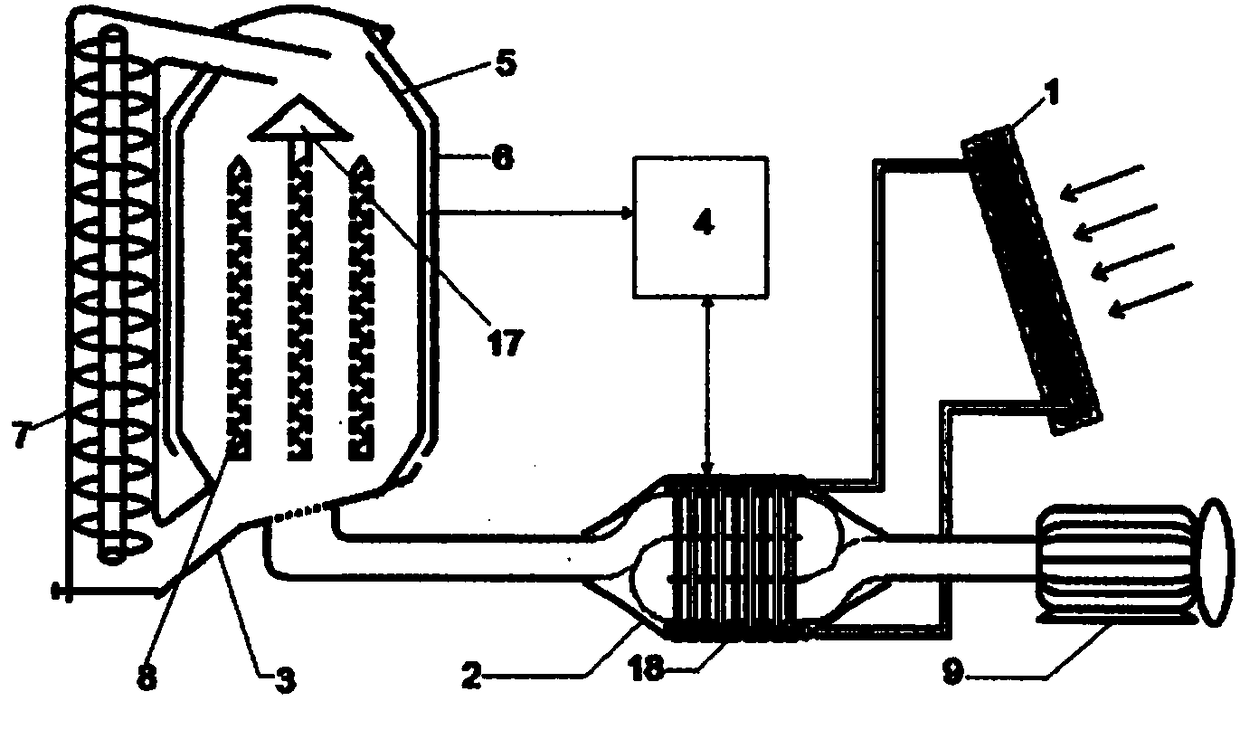

Intelligent cereal drying device based on solar energy

A technology for grain drying and solar energy, applied in the directions of solar thermal energy, grain drying, solar collectors, etc., can solve the problems of backward drying process, many models, heat source pollution, etc., and achieve high economic benefits, broad application prospects, high efficiency The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

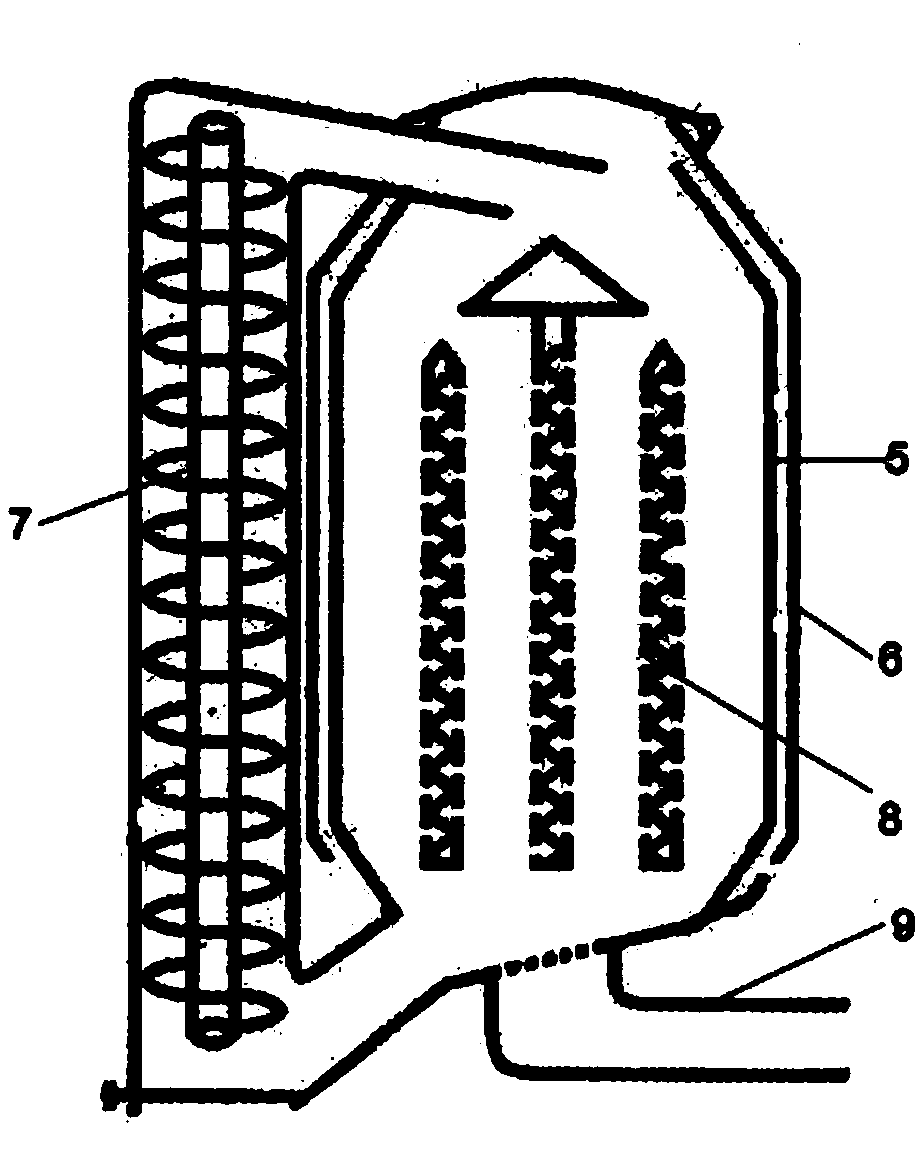

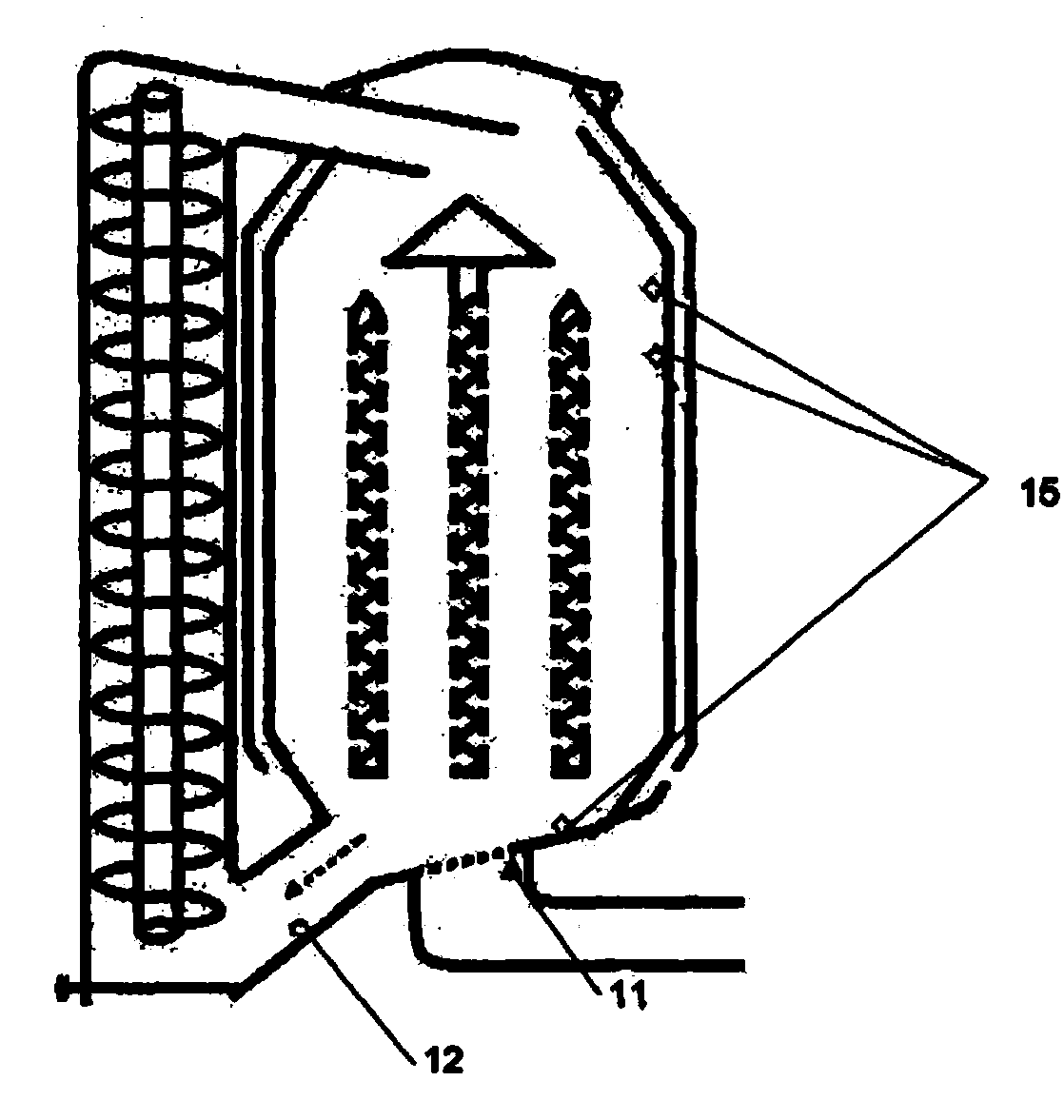

Method used

Image

Examples

Embodiment

[0036] The preparation process of the humidity sensitive sensor is:

[0037] Step 1, cleaning, soak the ceramic substrate with the finger electrode in ethanol for 2 hours, then ultrasonically clean it for 20 minutes, rinse it several times with deionized water, and dry it for later use;

[0038] Step 2, Coating Sensitive Materials:

[0039] ZrO 2 Nanoparticles and CaCO 3 The particles are mixed to form sensitive material A; the ZrO 2 Nanoparticles and BaCO 3 The particles are mixed to form sensitive material B; the ZrO 2 Mix the nanoparticles with NiO nanoparticles to form a sensitive material C; mix the sensitive materials A, B, and C obtained above, put them in a mortar, then add an appropriate amount of deionized water dropwise, and grind for 12 hours to form a paste. Put the mixture in a crucible, and calcined at 470°C and 950°C for 50min and 160min respectively, and then make the calcined mixture into a paste again, and coat it on the ceramic substrate with finger el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com