Positive pressure atmosphere aluminizing reinforcing method for nickel-based alloy, nickel-based alloy workpiece and application

A nickel-based alloy and atmosphere technology, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of reducing aluminized quality, hindering aluminized, metal surface oxidation, etc., and achieve the quality of aluminized layer High efficiency, easy operation and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preferably, the preparation method of the aluminizing agent comprises: according to the composition of the aluminizing agent, taking aluminum powder, NH 4 Cl and Al 2 o 3 Mix and ball mill, mix well and set aside. Wherein, the rotating speed of the ball mill is 100-200r / min, and the ball milling time is 5-20h.

[0047] In some preferred embodiments, the aluminizing strengthening method includes: keeping the pressure of the protective atmosphere at 0.03-0.05 MPa during the aluminizing process.

[0048] Preferably, the protective atmosphere is selected from an inert gas atmosphere, such as an Ar atmosphere.

[0049] In some preferred embodiments, the aluminized strengthening method includes:

[0050] The nickel-based alloy substrate is completely covered with aluminizing agent, and then vacuum-dried,

[0051] After that, put the nickel-based alloy substrate covered with aluminizing agent into the vacuum furnace, and then seal and vacuum the inner cavity of the vacuum f...

Embodiment 1

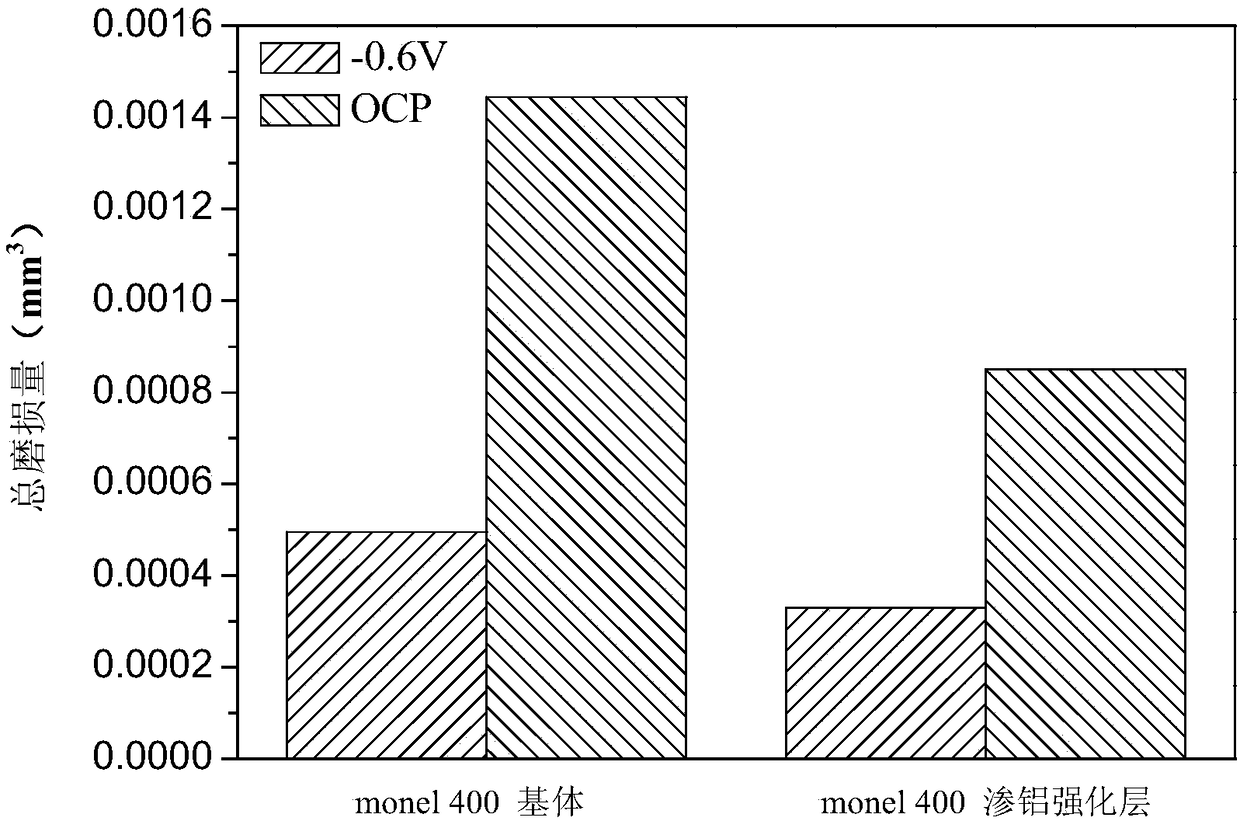

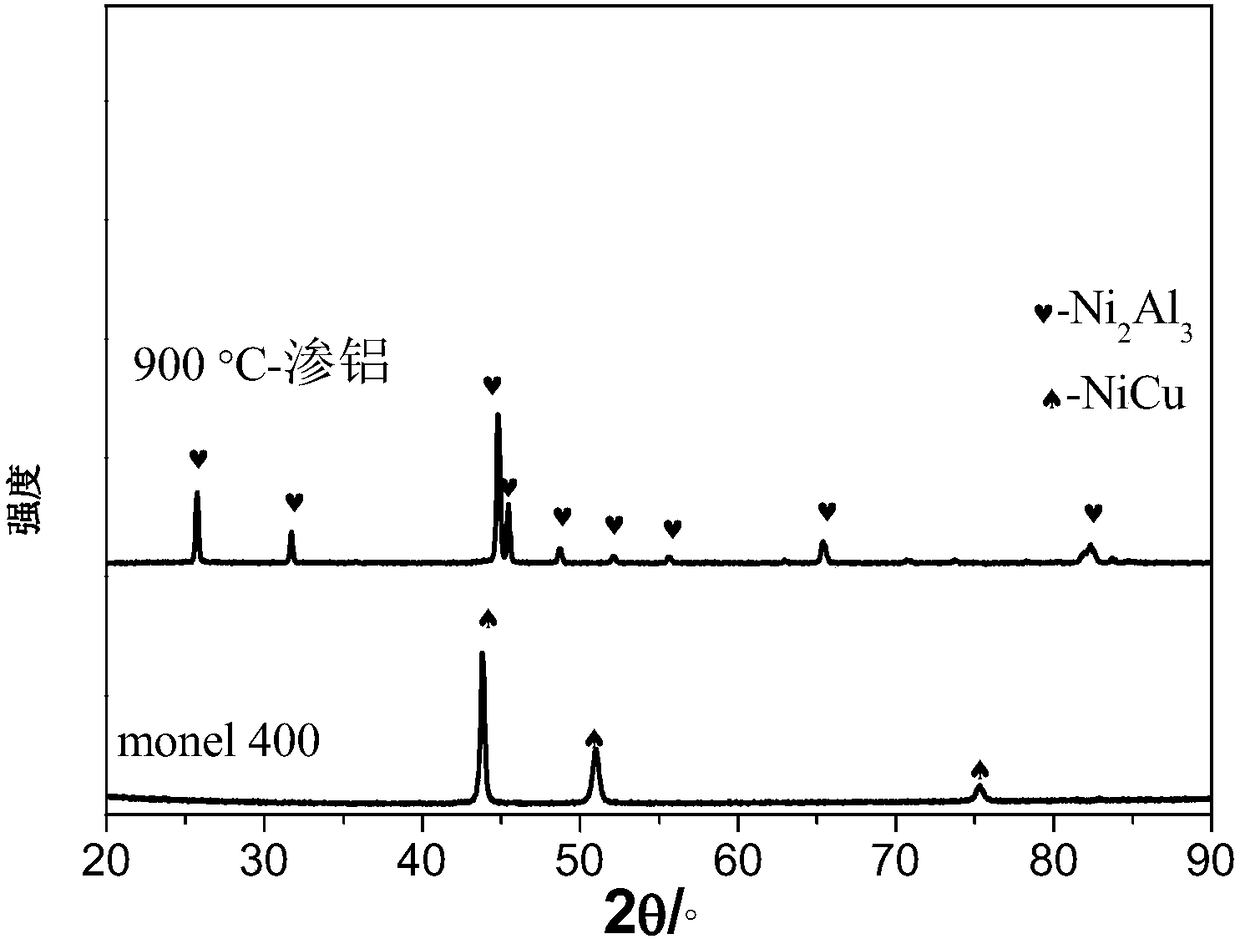

[0073] The Ni-Al strengthening layer on the surface of the nickel-based alloy in this example is composed of dense Ni with a thickness of 87 μm. 2 Al 3 Composed of the coating, the aluminized strengthening layer is a metallurgical bonding layer. Compared with the nickel-based alloy, the hardness is increased by 4 times, the wear resistance is increased by 1.7 times, and the corrosion resistance is increased by 1.8 times. Figure 1-Figure 6 It is the performance parameter diagram of the nickel-based alloy surface aluminized strengthening layer of this embodiment and the performance comparison diagram with the nickel-based alloy substrate.

[0074] The positive pressure atmosphere aluminizing strengthening method of the Ni-Al strengthening layer on the surface of the nickel-based alloy can be carried out according to the following steps:

[0075] (1) Ultrasonic cleaning of the nickel-based alloy substrate, preparation of the nickel-based alloy sample to be processed, with a bri...

Embodiment 2

[0083] The Ni-Al strengthening layer on the surface of the nickel-based alloy in this embodiment is composed of a dense Ni2Al3 coating with a thickness of 98 μm. The aluminized layer is a metallurgical bonding layer. Compared with the nickel-based alloy, the hardness is increased by 4.3 times, and the wear resistance is increased by 1.5. times, corrosion resistance increased by 2 times.

[0084] The positive pressure atmosphere aluminizing strengthening method of the Ni-Al strengthening layer on the surface of the nickel-based alloy is carried out according to the following steps:

[0085] (1) Ultrasonic cleaning of the nickel-based alloy substrate, preparation of the nickel-based alloy sample to be processed, with a bright surface and no oxide layer, and then ultrasonic cleaning of the sample to remove surface grease, etc. The cleaning agents are ethanol and acetone;

[0086] (2) prepare aluminizing agent, wherein the weight percent of aluminizing agent is: 20% aluminum powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com