Method for preparing, storing, using and repairing battery or capacitor under negative pressure

A battery and capacitor technology, applied in electrolytic capacitors, secondary battery manufacturing, secondary battery repair/maintenance, etc., can solve problems such as dangerous hidden performance, attenuation, battery performance deterioration, etc., to achieve stable electrode interface, improve performance and quality , the effect of avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of a lithium-ion power battery applied to a new energy vehicle.

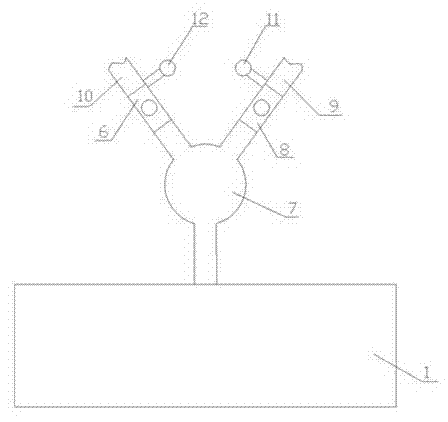

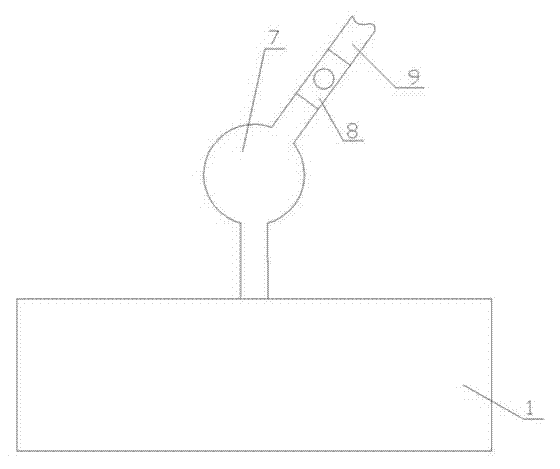

[0020] Embodiment 1 is achieved by adopting the following technical solutions: as figure 1 As shown, a three-channel 7 is installed in one place of the battery cavity 1, and a valve is arranged on each of the upper ends of the three channels 7. A part of one of the valves 8 is connected to a negative pressure pipe 9, and a vacuum gauge 11 is provided at an appropriate position of the negative pressure pipe 9; Connect one part of the battery cavity 1 to be injected with the electrolyte to the three-channel 7 of the external device, and after confirming that the entire system connection is airtight and leak-free, open the valve 8 and connect the negative pressure tube 9 to pump out the inside of the battery cavity 1 The gas inside is in a negative pressure state, open the valve 6 and connect the pipe 10, inject the electrolyte according to the set amount, and close the valve 8; in th...

Embodiment 2

[0022] Embodiment 2: The restoration of the lithium-ion power battery applied to new energy vehicles.

[0023] Embodiment 2 is realized by adopting the following technical scheme: the lithium-ion power battery manufactured in the above-mentioned embodiment 1 is put into use in a new energy vehicle, and the performance of individual batteries declines, deteriorates, and the like. We can remove the battery from the new energy vehicle. Such as figure 1 , Figure 4 As shown, according to the set operating procedures, the battery is connected to its external device, and its internal sampling, analysis, tracking research and repair are carried out to restore its good performance and put it into use again.

Embodiment 3

[0024] Embodiment 3: Preparation of batteries or capacitors.

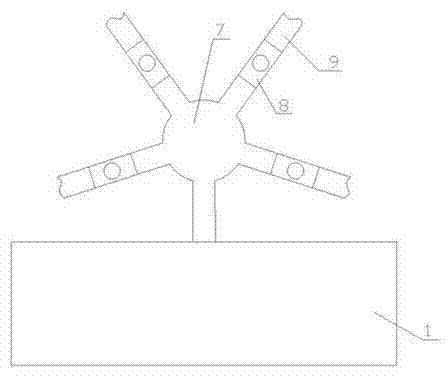

[0025] Embodiment 3 is achieved by adopting the following technical solutions: as figure 2As shown, the channel 7 of its external connection device is multi-channel, and it is connected with the battery or capacitor cavity 1, and the other ports of the multi-channel 7 are respectively connected with a valve, and one valve 8 is connected with the negative pressure tube 9 connections, and the rest of the valves are each connected to a pipeline. In this way, the channel 7 is respectively connected to the pipelines of the vacuum pump, electrolyte, argon, additives, etc. through valves, and liquid and gas can be drawn from and injected into the battery or capacitor cavity 1 at will.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com