Method for testing fluorescence signal of oxygen concentration in water by enhancing oxygen sensitive film

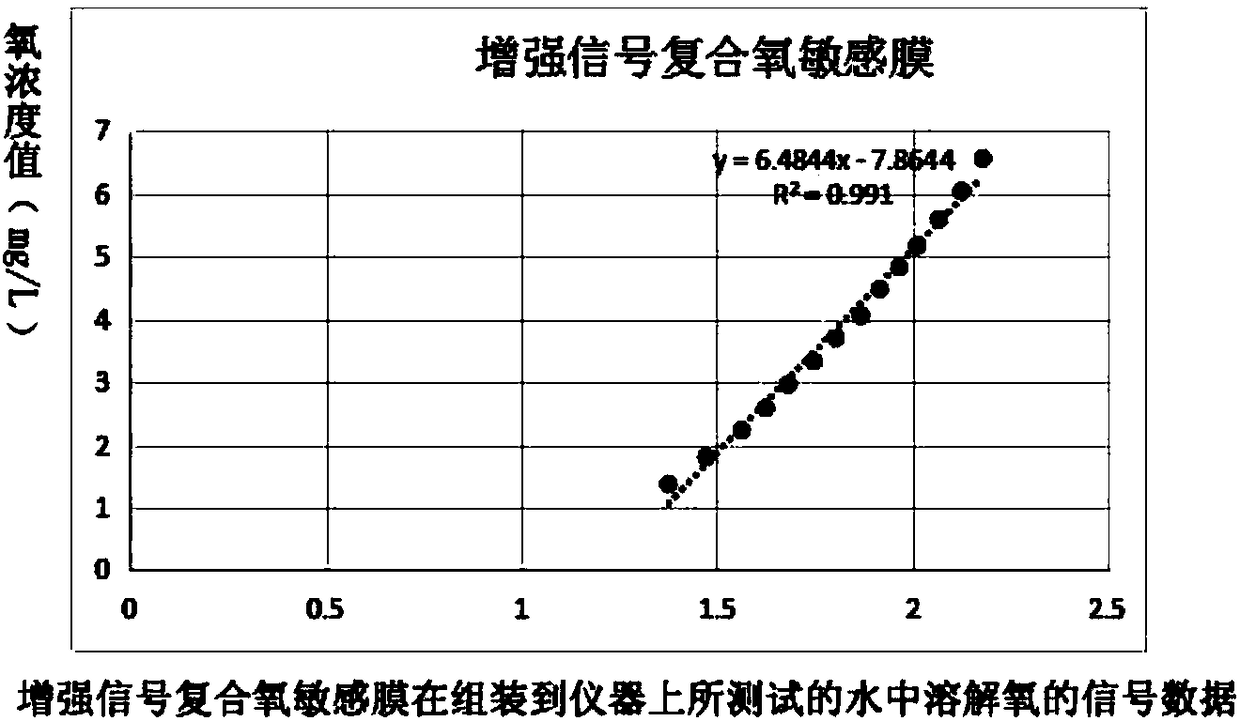

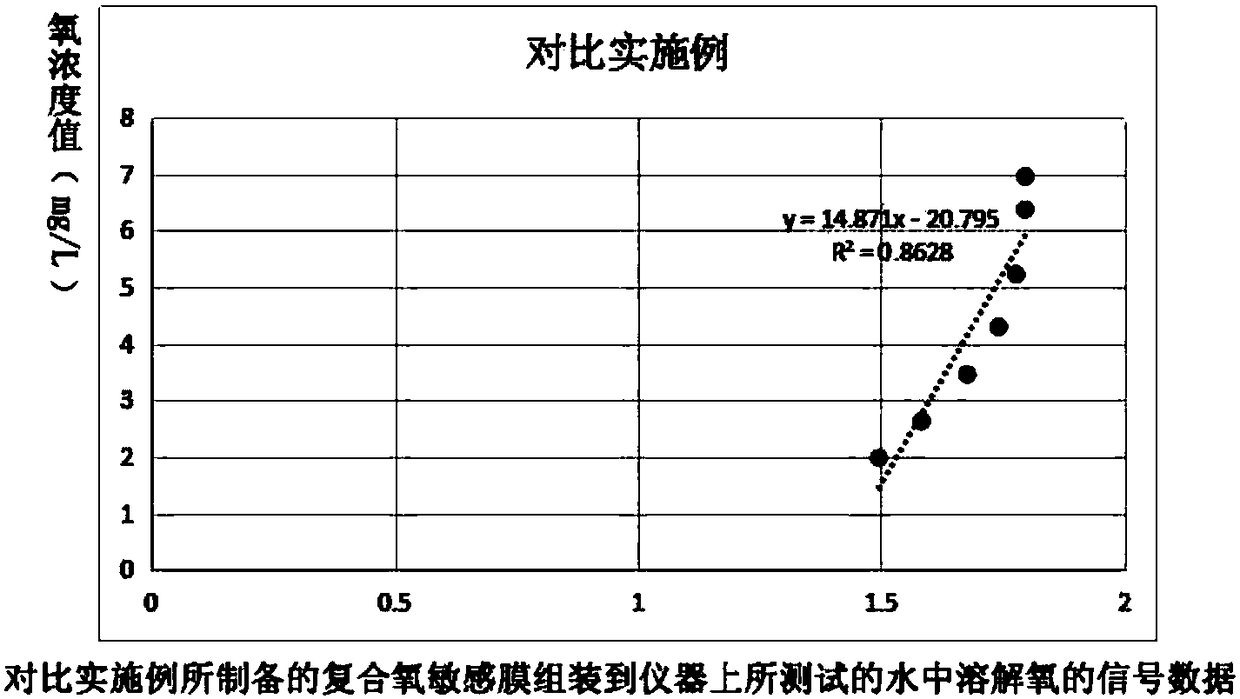

An oxygen-sensitive film and fluorescent signal technology, which is applied in the direction of fluorescence/phosphorescence, measuring devices, and material analysis through optical means, can solve the problems of weak and unstable signals, achieve short film-making time, easy operation, and improve accuracy degree and the effect of linear correlation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

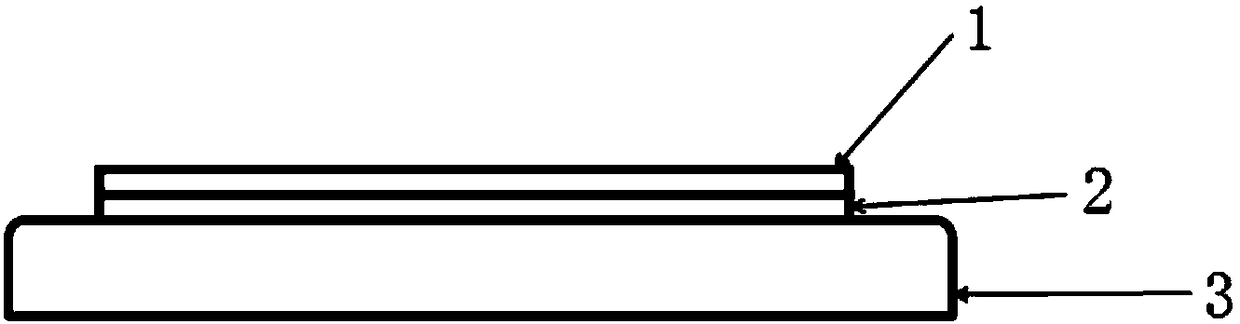

[0028] Dissolve 4ml of tetraethyl orthosilicate and 3ml of dimethyldimethoxysilane in 10ml of ethanol and stir, slowly add 1ml of deionized water and 0.1ml of hydrochloric acid and stir for 2 hours, weigh 1.5g of barium sulfate Add the above solution and stir for 3h to form a milky white turbid solution. Soak the prepared oxygen-sensitive film (adhesive tape on one side of the substrate) in the turbid solution by dip coating, then take it out, put it in an oven for heat curing (30°C for 2h, 50°C for 2h, 80°C for 4h), and you can get Composite oxygen sensitive membrane.

Embodiment 2

[0030] Dissolve 4ml tetraethyl orthosilicate and 3ml dimethyldimethoxysilane in 10ml ethanol and stir, slowly add 1ml deionized water and 0.1ml hydrochloric acid and stir for 2 hours, weigh 0.4g carbon black The powder was added to the above solution and stirred for 3h to form a black turbid liquid. Soak the prepared oxygen-sensitive film (adhesive tape on one side of the substrate) in the turbid solution by dip coating, then take it out, put it in an oven for heat curing (30°C for 2h, 50°C for 2h, 80°C for 4h), and you can get Composite oxygen sensitive membrane.

Embodiment 3

[0032] Dissolve 4.5ml of tetraethyl orthosilicate and 2.5ml of dimethyldimethoxysilane in 10ml of ethanol and stir, slowly add 1ml of deionized water and 0.1ml of hydrochloric acid and stir for 2 hours, weigh 2.0g Barium sulfate was added to the above solution and stirred for 3 hours to form a milky white turbid solution. Soak the prepared oxygen-sensitive film (adhesive tape on one side of the substrate) in the turbid solution by dip coating, then take it out, put it in an oven for heat curing (30°C for 2h, 50°C for 2h, 80°C for 4h), and you can get Composite oxygen sensitive membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com