Nonuniform wet silicon-based micro-channel phase change heat exchanger with communicated top

A phase change heat exchanger and micro-channel technology, applied in indirect heat exchangers, heat exchanger types, heat storage equipment, etc., can solve the problem of asynchronous, different channel flow and heat transfer characteristics pulsation, parallel channel instability, etc. problem, to achieve the effect of stable heat transfer and low start-up overtemperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

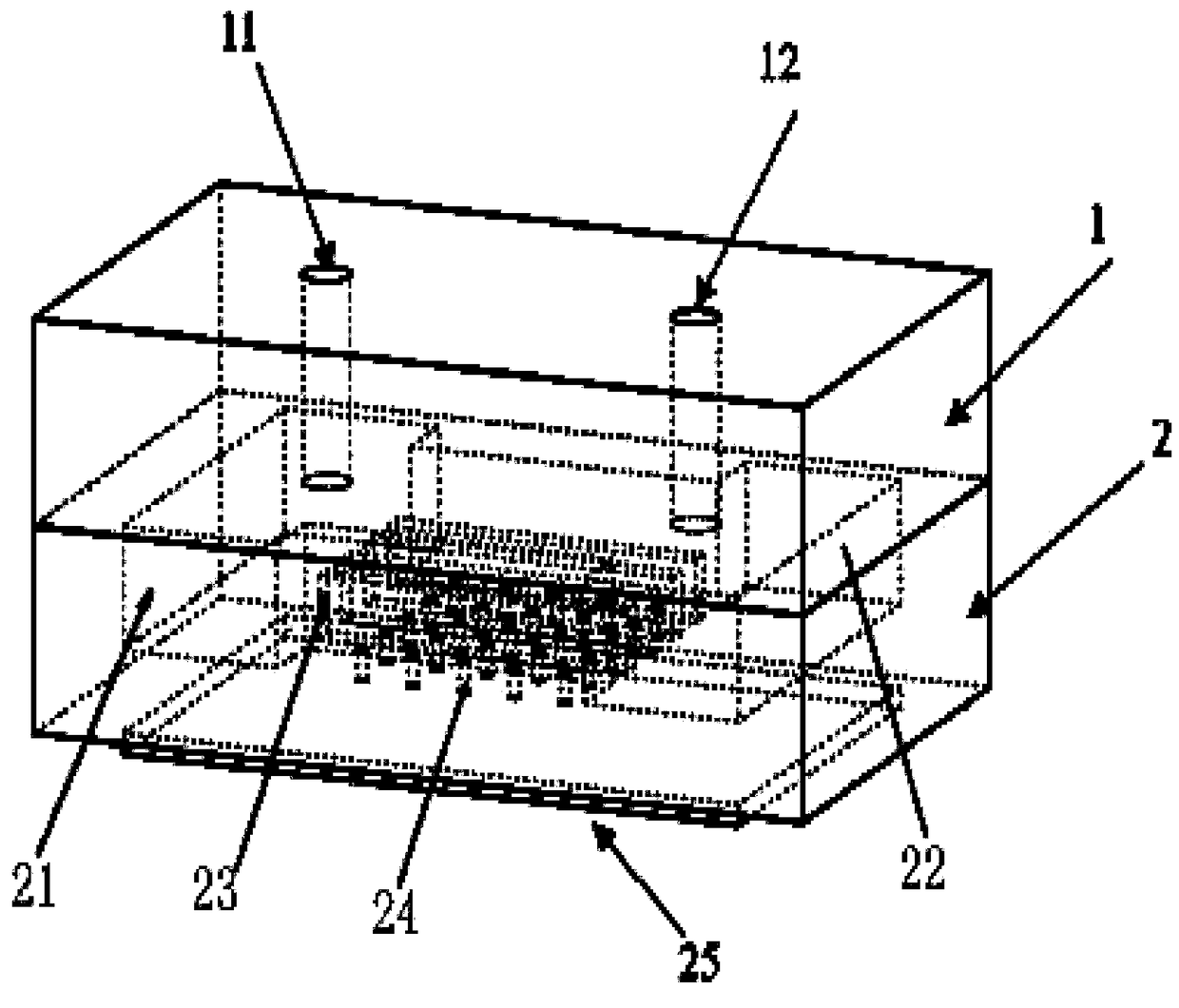

[0024] The present invention proposes a non-uniform wettability microchannel phase-change heat exchanger connected at the top. By adopting open parallel microchannels, nucleation hole arrays and non-uniform wettability surfaces, low start-up overtemperature and high heat exchange can be realized at the same time. Thermal coefficient and critical heat flux and stable phase change heat transfer. The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

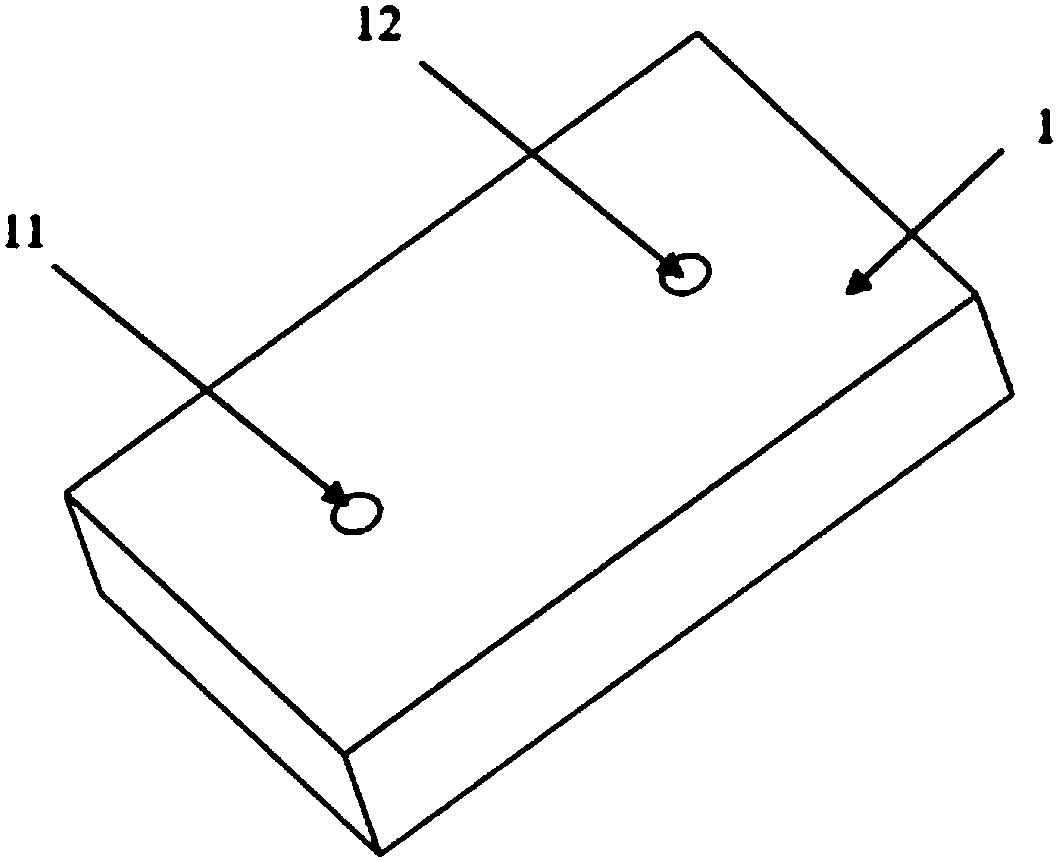

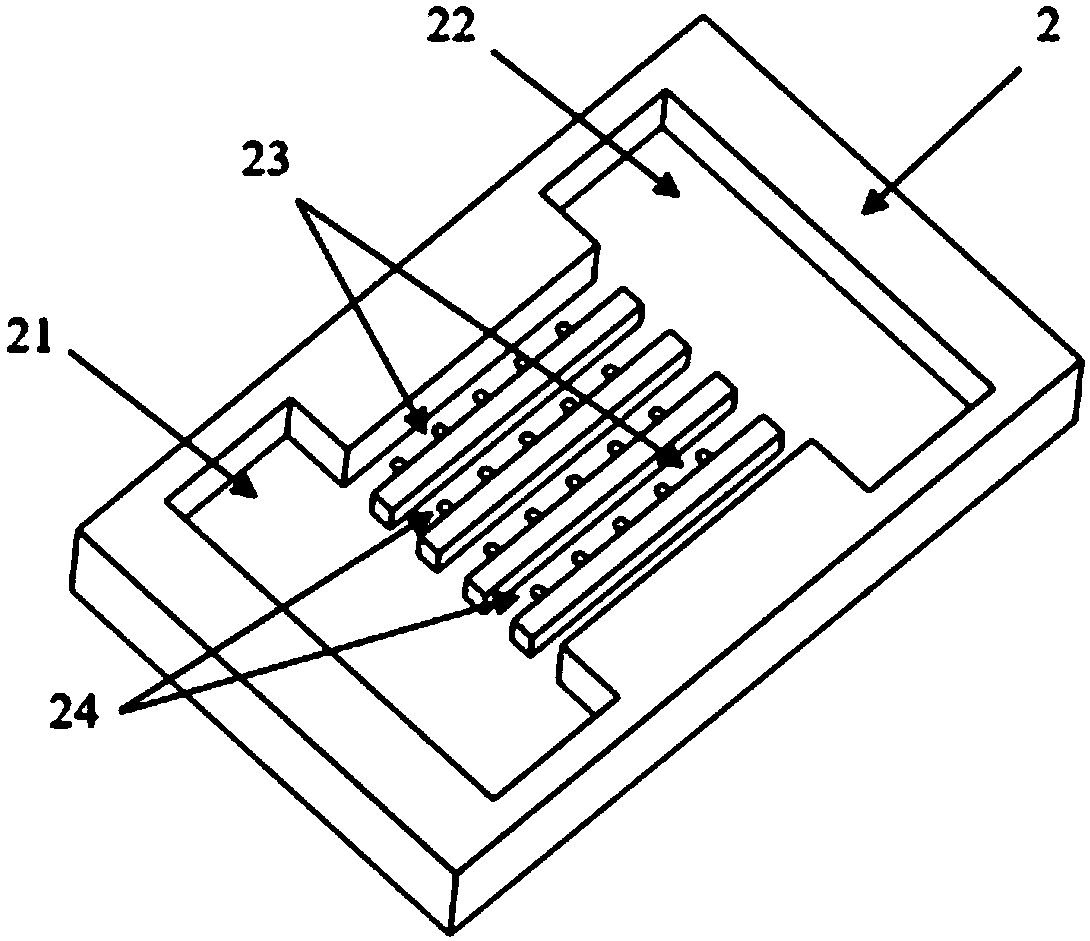

[0025] figure 1 Shown is the three-dimensional assembly diagram of the non-uniform wettability microchannel phase-change heat exchanger connected at the top. The microchannel phase-change heat exchanger is formed by anodic bonding of the upper glass 1 and the bottom silicon 2. A liquid inlet 11 and a liquid outlet 22 are arranged on the upper surface; a liquid inlet pool 21, a liquid outlet pool 22, an open parallel microchannel 23 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com