Screw type water source gas engine-driven heat pump water chiller/heater unit and operation method

A cold and hot water unit, screw type technology, applied in the operation mode of the machine, refrigeration components, refrigerators, etc., can solve the problems of low energy utilization efficiency, large performance impact, heating capacity and efficiency attenuation, etc., and achieve a one-time improvement. Energy utilization, obvious social benefits, and the effect of alleviating power shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

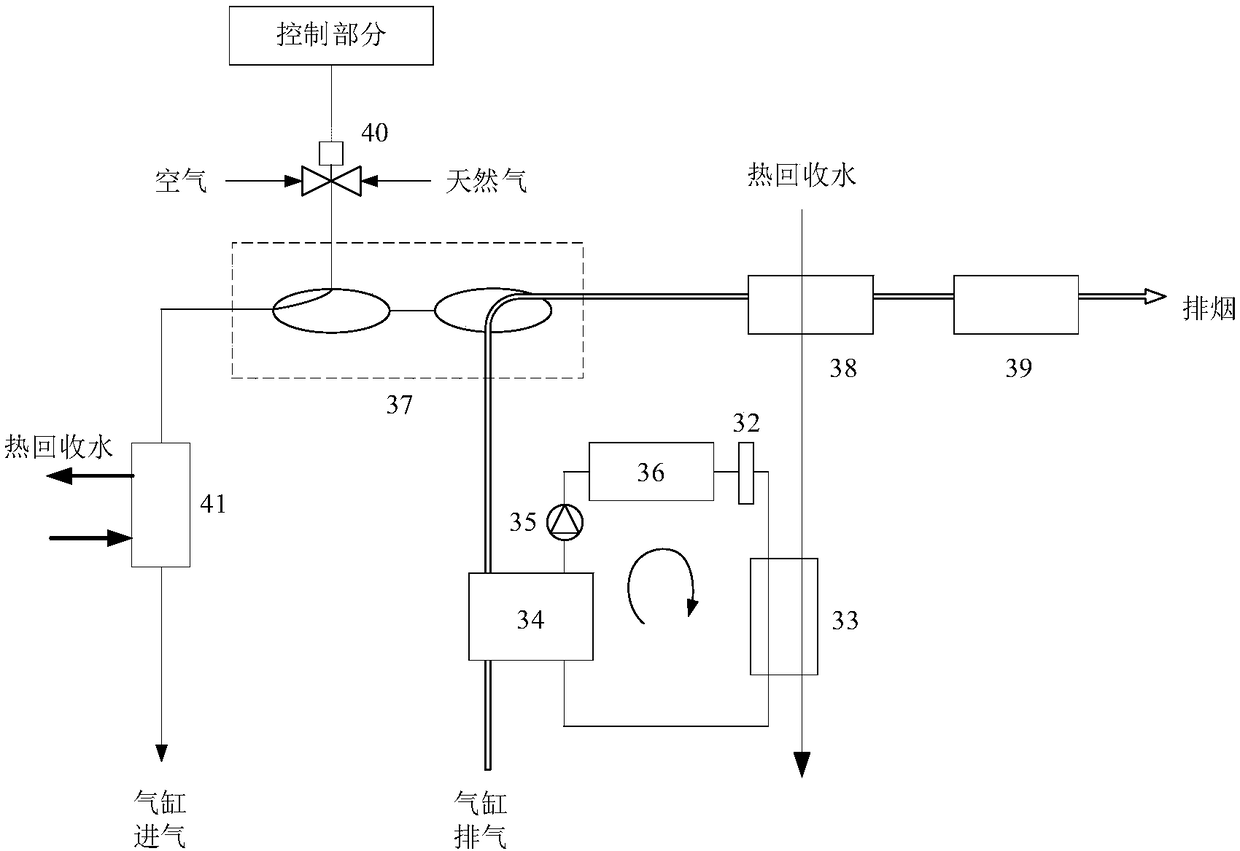

[0019] Such as figure 1 As shown, the screw-type water source gas engine heat pump cold and hot water unit includes a power system, a refrigerant system, an oil return system and an engine waste heat recovery system, of which:

[0020] The power system mainly includes a gas engine 1, a flywheel 2, a speed-up clutch 3 and a coupling 4; the speed-up clutch 3 is connected with the gas engine 1 by a flywheel 2, and the speed-up clutch 3 is connected with a screw refrigeration compressor 5 Connected by coupling 4, the speed-increasing clutch 3 is used to increase the output speed of the gas engine 1 and control the on-off of power transmission. Noise and vibration.

[0021] The refrigerant system mainly includes screw refrigeration compressor 5, exhaust stop valve 6, oil separator 7, stop check valve 8, water-cooled condenser 9, dry filter 11, solenoid valve 12, electronic expansion valve 15, dry Type evaporator 16, gas-liquid separator 17, suction filter 18, suction stop valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com