Pressurized densification sintering method for laterite nickel ore

A laterite nickel ore and densification technology, applied in the field of iron and steel metallurgy, can solve the problems of no patents and reports on enhanced sintering, unfavorable blast furnace production, and low liquid phase generation, and achieves improvement of sinter output, reduction of pore size and Quantity, the effect of increasing yield and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

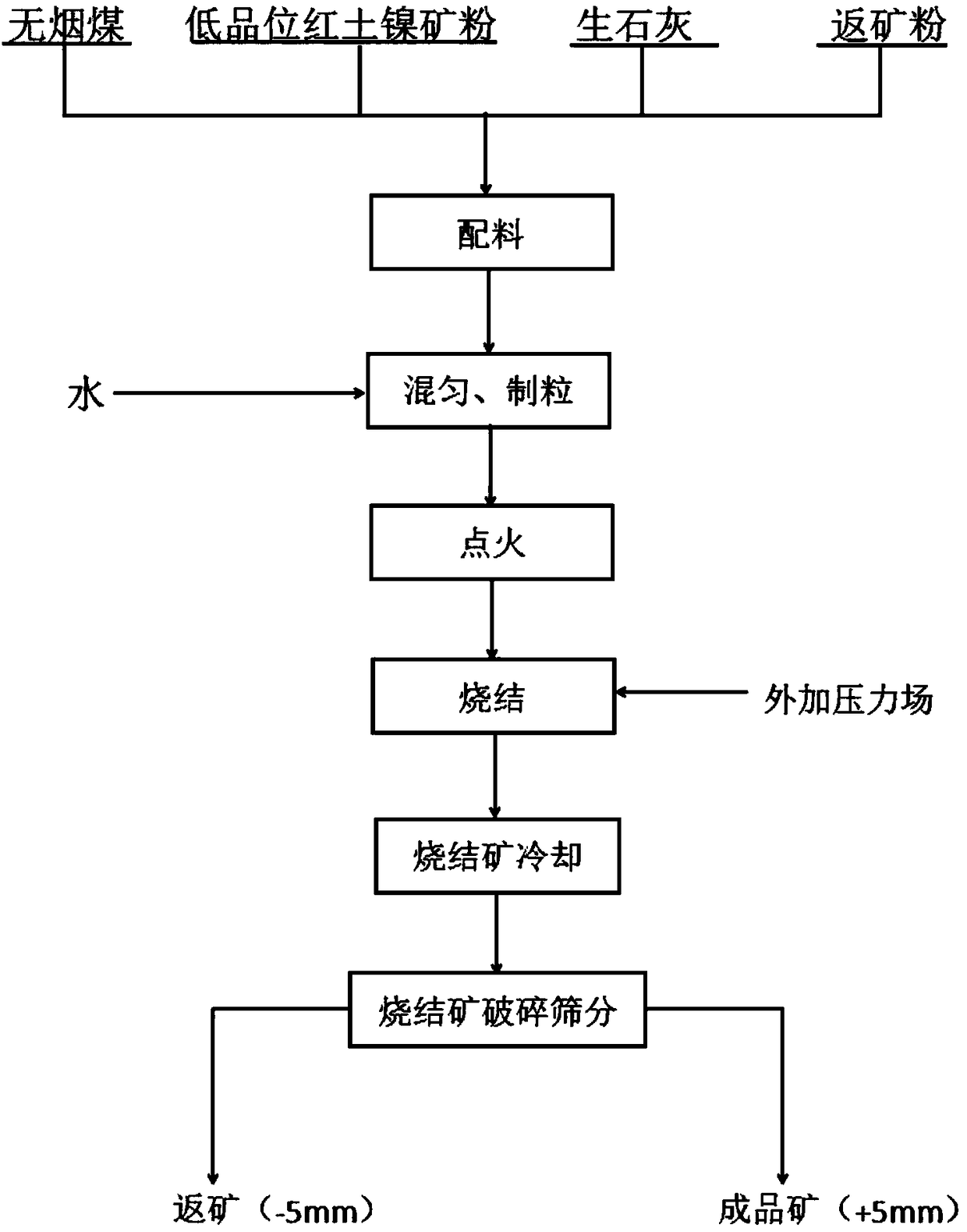

[0032] A kind of method of pressure densification sintering of laterite nickel ore, see figure 1 , including the following steps:

[0033] (1) Ingredients: Mix 53wt% lateritic nickel ore with a nickel content of 1.4%, 30wt% return ore powder, 7.5wt% anthracite, and 9.5wt% quicklime to obtain a mixture.

[0034] (2) Mixing and granulation: Add water to the mixture, and adjust the water level of the mixture to 17.0%. Mix in a cylinder mixer, control the speed of the mixer to 25 r min -1 , the filling rate was 15%, and the granulation time was 5 minutes to obtain a sintered material with a moisture content of 17.0%. In the sintered material, the sintered material with a particle size greater than 0.5 mm was 96 wt%, and the sintered material with a particle size greater than 1 mm was 86 wt%.

[0035] (3) Ignition: put the sintered material in step (2) into the sintering machine, and the filling height of the sintered material layer is 680mm. Control the ignition negative press...

Embodiment 2

[0041] A method for pressurized and densified sintering of laterite nickel ore, comprising the following steps:

[0042] (1) Ingredients: Mix 53wt% lateritic nickel ore with a nickel content of 1.4%, 30wt% return ore powder, 7.5wt% anthracite, and 9.5wt% quicklime to obtain a mixture.

[0043] (2) Mixing and granulation: Add water to the mixture, and adjust the water level of the mixture to 17.0%. Mix in a cylinder mixer, control the speed of the mixer to 25 r min -1 , the filling rate was 15%, and the granulation time was 5 minutes to obtain a sintered material with a moisture content of 17.0%. In the sintered material, the sintered material with a particle size greater than 0.5 mm was 96 wt%, and the sintered material with a particle size greater than 1 mm was 86 wt%.

[0044] (3) Ignition: put the sintered material in step (2) into the sintering machine, and the filling height of the sintered material layer is 680mm. Control the ignition negative pressure to 5kPa, the ig...

Embodiment 3

[0050] A method for pressurized and densified sintering of laterite nickel ore, comprising the following steps:

[0051] (1) Ingredients: Mix 57wt% lateritic nickel ore with a nickel content of 1.4%, 30wt% return ore powder, 6.5wt% anthracite, and 6.5wt% quicklime to obtain a mixture.

[0052] (2) Mixing and granulation: Add water to the mixture, and adjust the water level of the mixture to 17.0%. Mix in a cylinder mixer, control the speed of the mixer to 25 r min -1 , the filling rate was 15%, and the granulation time was 5 minutes to obtain a sintered material with a moisture content of 17.0%. In the sintered material, the sintered material with a particle size greater than 0.5 mm was 96 wt%, and the sintered material with a particle size greater than 1 mm was 86 wt%.

[0053] (3) Ignition: put the sintered material in step (2) into the sintering machine, and the filling height of the sintered material layer is 680mm. Control the ignition negative pressure to 5kPa, the ig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com