Preparation method of two-component high-adhesion pollution flashover-prevention fluorocarbon coating for hard mask

A technology of fluorocarbon coating and adhesion, which is applied in the field of preparation of two-component high-adhesion hard film anti-fouling flash fluorocarbon coating, which can solve the problems of easy scratch, low coating hardness and low adhesion. Achieve the effects of improving mechanical strength, improving adhesion, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

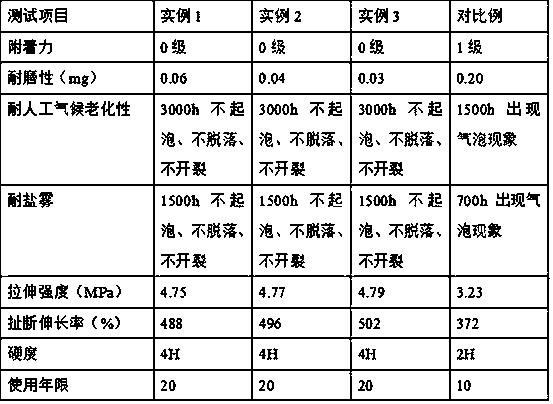

Examples

example 1

[0024] Weigh tea leaves, red bayberry and fresh grapes according to the mass ratio of 1:1:2, wash them once with deionized water, put them into a tissue pulverizer, pulverize for 20 minutes to obtain a mixed pulverized product, mix the pulverized product, cellulase and fruit Glue enzyme is mixed according to the mass ratio of 10:1:1 and put into the enzymolysis tank, and the enzymolysis product is obtained at 28°C for 6 hours; then the enzymolysis product and glucose are mixed according to the mass ratio of 6:1. As a fermentation substrate, put the fermentation substrate into a fermenter, seal the mouth of the fermenter with plastic wrap, and seal and ferment at a temperature of 30°C for 10 days. After the fermentation is over, filter and separate to obtain the fermentation filtrate; calculated in parts by weight , weighed 30 parts of the above fermentation filtrate, 40 parts of fluorocarbon resin with a solid content of 55% and a fluorine content of 35%, 15 parts of sodium dih...

example 2

[0026]Weigh tea leaves, red bayberry and fresh grapes according to the mass ratio of 1:1:2, wash them once with deionized water, put them into a tissue pulverizer, pulverize for 25 minutes to obtain a mixed pulverized product, and mix the pulverized product with cellulase and fruit Glue enzyme is mixed according to the mass ratio of 10:1:1 and put into the enzymolysis tank, and the enzymolysis product is obtained at 31°C for 7 hours; then the enzymolysis product and glucose are mixed according to the mass ratio of 6:1. As a fermentation substrate, put the fermentation substrate into a fermenter, seal the mouth of the fermenter with a plastic wrap, and seal and ferment at a temperature of 33°C for 13 days. After the fermentation is over, filter and separate to obtain a fermentation filtrate; calculated in parts by weight , weighed 35 parts of the above fermentation filtrate, 45 parts of fluorocarbon resin with a solid content of 60% and a fluorine content of 38%, 18 parts of sod...

example 3

[0028] Weigh tea leaves, red bayberry and fresh grapes according to the mass ratio of 1:1:2, wash them twice with deionized water, put them into a tissue pulverizer, pulverize for 30 minutes to obtain a mixed pulverized product, and mix the pulverized product with cellulase and fruit Glue enzyme is mixed according to the mass ratio of 10:1:1 and put into the enzymolysis tank, and the enzymolysis product is obtained at 35°C for 8 hours; then the enzymolysis product and glucose are mixed according to the mass ratio of 6:1. As a fermentation substrate, put the fermentation substrate into a fermenter, seal the mouth of the fermenter with plastic wrap, and seal and ferment at a temperature of 35°C for 15 days. After the fermentation is over, filter and separate to obtain the fermentation filtrate; calculated in parts by weight , weighed 40 parts of the above fermentation filtrate, 50 parts of fluorocarbon resin with a solid content of 65% and a fluorine content of 40%, 20 parts of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com