Epoxy resin compositions, prepregs, laminates and printed circuit boards

A technology of epoxy resin and composition, which can be used in printed circuits, printed circuit parts, circuit substrate materials, etc., and can solve problems such as high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

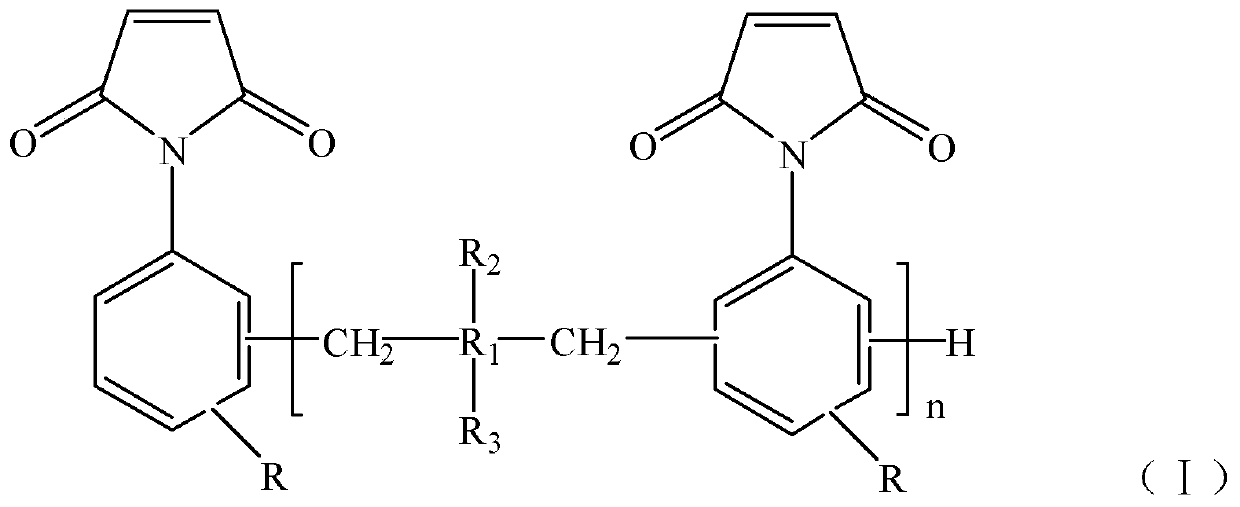

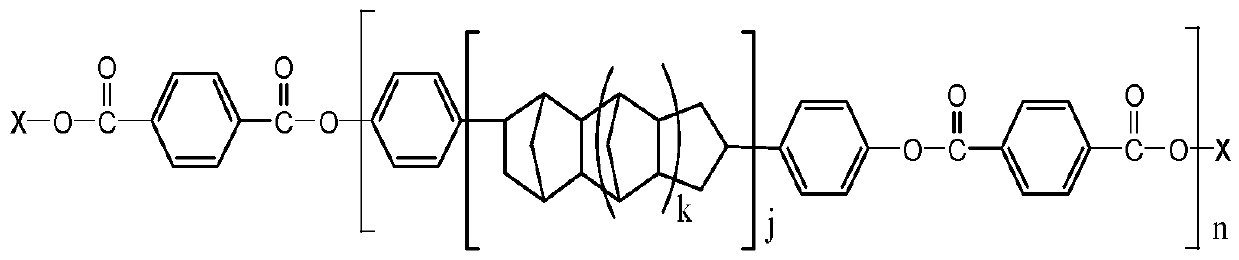

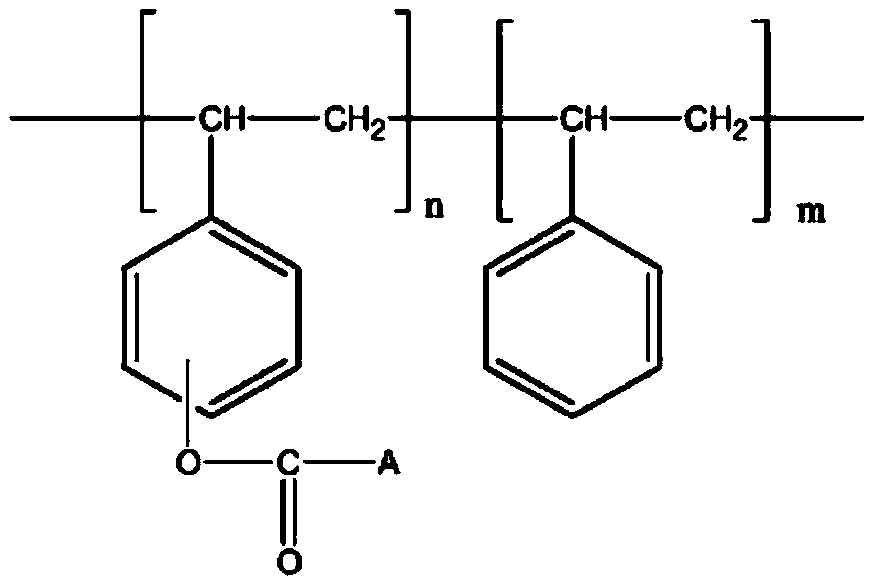

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-3

[0145] Put epoxy resin, maleimide, active ester, curing accelerator, and filler into the container according to the formula shown in Table 1 and a suitable solvent, stir to mix and disperse evenly, and make glue, and adjust the solution solid with solvent content to 60%-70% to make a glue solution, that is, to obtain a halogen-free thermosetting resin composition glue solution, impregnate the glue with 2116 electronic grade glass fiber cloth, bake in an oven to form a prepreg, take 4 pieces of 2116 prepreg, double-sided Cover with 18um thick electrolytic copper foil, do vacuum lamination in hot press, cure at 220℃ / 120min, press pressure 45kg / cm 2 , made of copper clad laminate with a thickness of 0.50mm. The performance test results are shown in Table 2.

[0146] Each component used in embodiment and comparative example is described in detail as follows:

[0147] (A) epoxy resin

[0148] (A-1) Biphenyl type epoxy resin: NC-3000-H (Nippon Kayaku)

[0149] (A-2) Dicyclopenta...

Embodiment 5-8 and comparative example 4-6

[0169]Put epoxy resin, maleimide, active ester, cyanate ester, curing accelerator, and filler into the container according to the formula shown in Table 3 and a suitable solvent, stir to make it mix and disperse evenly, and make glue. The solvent adjusts the solid content of the solution to 60%-70% to make a glue solution, that is, a halogen-free thermosetting resin composition glue solution, impregnate the glue with 2116 electronic grade glass fiber cloth, bake it in an oven to form a prepreg, and take 4 2116 prepregs , both sides are covered with 18um thick electrolytic copper foil, vacuum laminated in a hot press, cured at 220°C / 120min, press pressure 45kg / cm 2 , made of copper clad laminate with a thickness of 0.50mm. The performance test results are shown in Table 4.

[0170] Table 3. Resin composition formulation (parts by weight)

[0171]

[0172] Table 4. Base material property values

[0173]

[0174]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com