Flexible metal organic frame material and preparation method and application thereof

A technology of organic frameworks and flexible metals, applied in the field of flexible metal organic framework materials and their preparation, can solve the problems of complex synthesis steps, unstable structure of flexible metal organic framework materials, low CO2 adsorption selectivity, etc., and achieve simple preparation process, Enhanced flexibility and improved CO2 adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] A method for preparing a flexible metal-organic framework material, comprising:

[0037] (1) 130 molar parts of N,N-dimethylformamide, 340 molar parts of ethanol, and 2200 molar parts of water are mixed to form a mixed solution, and 6 molar parts of fluoroboric acid are added to the mixed solution to form a mixed solvent;

[0038] (2) 1 molar part of cobalt nitrate hexahydrate, 1 molar part of 4,4'-bipyridyl, 0.8 molar part of 4-(1H-tetrazol-5-yl) benzoic acid obtained in step (1) In the mixed solvent, stir for 25 minutes to form a mixture;

[0039] (3) Place the mixture obtained in step (2) in a high-pressure reactor, heat it to 115°C in a closed manner and keep it for 72 hours, and then cool it to room temperature at a rate of 0.1°C per minute to obtain a reaction solution;

[0040] (4) Filtrating the reaction solution obtained in step (3) to obtain a filter body, and washing the filter body with ethanol to obtain pink rod-shaped crystals, that is, to obtain the init...

specific Embodiment 2

[0055] Flexible metal-organic framework materials, whose chemical formula is [Co 3 (tzba) 2 (bpy) 3 (F) 2 ]·DMF·C 2 h 5 OH·2H 2 O, where:

[0056] tzba is a negative dianion ligand of 4-(1H-tetrazol-5-yl)benzoic acid;

[0057] bpy is 4,4'-bipyridine, DMF is N,N-dimethylformamide; where:

[0058] The structural formulas of tzba and bpy are as follows:

[0059]

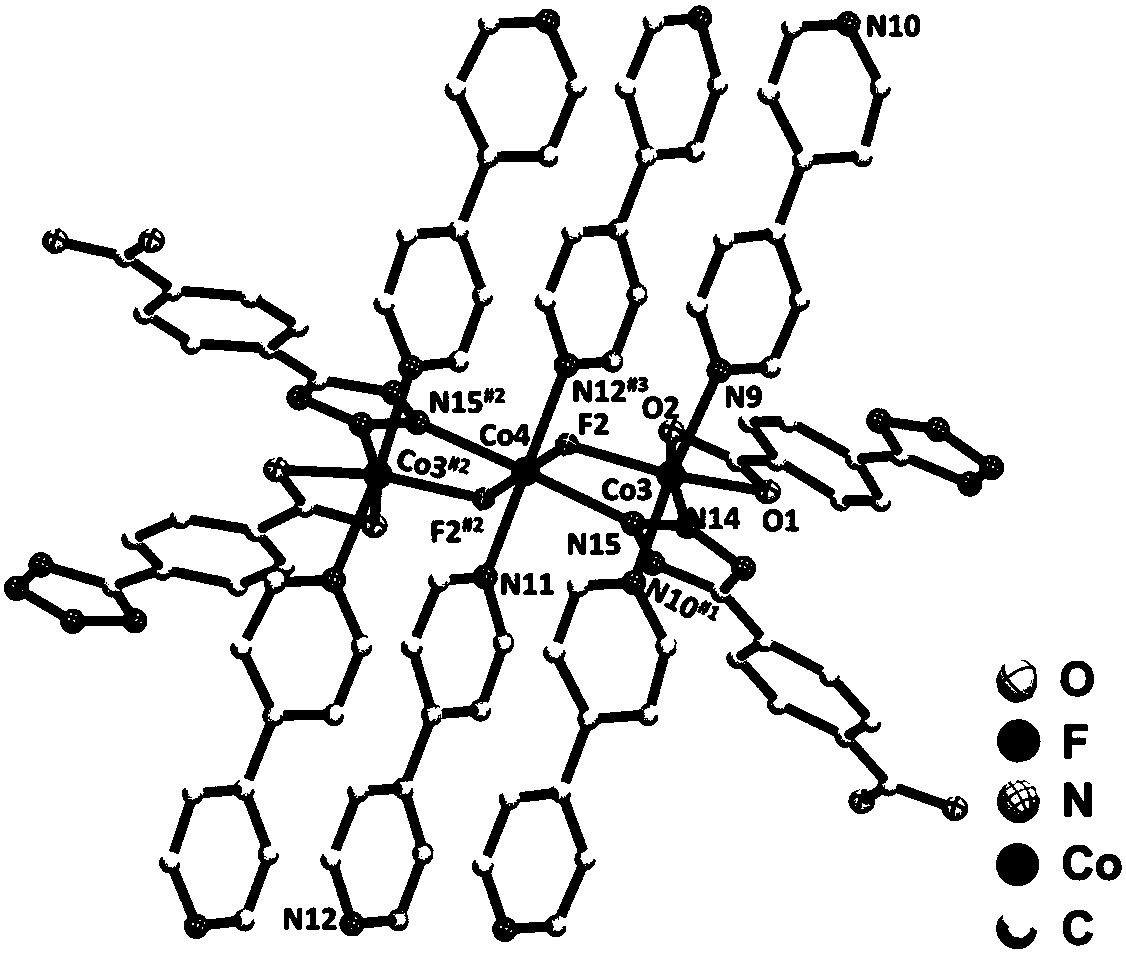

[0060] The flexible metal organic framework material contains cobalt-tetrazolium-fluorine trinuclear cluster building units, and forms a layered structure through the coordination extension of tzba, and the adjacent layers are connected by bpy to form a double interspersed three-dimensional framework.

[0061] A method for preparing a flexible metal-organic framework material, comprising:

[0062] (1) 120 molar parts of N,N-dimethylformamide, 320 molar parts of ethanol, and 2110 molar parts of water are mixed to form a mixed solution, and 5 molar parts of fluoroboric acid are added to the mixed solution to f...

specific Embodiment 3

[0069] Flexible metal-organic framework materials, whose chemical formula is [Co 3 (tzba) 2 (bpy) 3 (F) 2 ]·DMF·C 2 h 5 OH·2H 2 O, where:

[0070] tzba is a negative dianion ligand of 4-(1H-tetrazol-5-yl)benzoic acid;

[0071] bpy is 4,4'-bipyridine, DMF is N,N-dimethylformamide; where:

[0072] The structural formulas of tzba and bpy are as follows:

[0073]

[0074] The flexible metal organic framework material contains cobalt-tetrazolium-fluorine trinuclear cluster building units, and forms a layered structure through the coordination extension of tzba, and the adjacent layers are connected by bpy to form a double interspersed three-dimensional framework.

[0075] A method for preparing a flexible metal-organic framework material, comprising:

[0076] (1) 140 molar parts of N,N-dimethylformamide, 360 molar parts of ethanol, and 2330 molar parts of water are mixed to form a mixed solution, and 7 molar parts of fluoroboric acid are added to the mixed solution to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com