High-strength coral aggregate concrete and preparation method thereof

A high-strength, concrete technology, applied in the field of concrete, can solve the problems that coral aggregate concrete cannot be pumped, achieve the effects of improving workability and microstructure, improving mechanical properties and impermeability, and reducing hydration temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

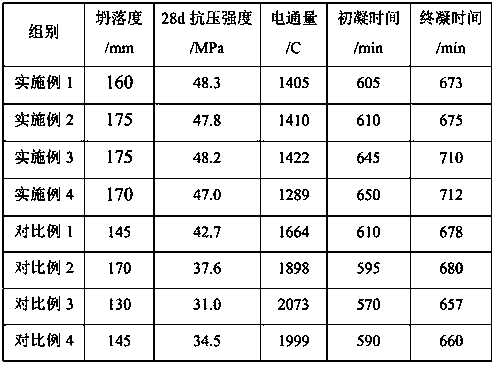

Examples

Embodiment 1

[0034] Embodiment 1 (without adding polycarboxylate high-performance water reducing agent)

[0035] The high-strength coral aggregate concrete is made of the following raw materials in parts by weight: 302 parts of low-heat marine Portland cement, 42 parts of fly ash floating beads, 42 parts of mineral powder, 13 parts of silica fume, 13 parts of metakaolin, 4 parts of nano-silica, 4 parts of polyaluminum chloride, 625 parts of coral reef sand, 940 parts of coral reef, 218 parts of sea water.

[0036] The preparation method is:

[0037] Step 1. At room temperature of 22°C, pre-wet the coral reef, coral reef sand and 1 / 10 mass of seawater for 60 seconds to obtain component A;

[0038] Step 2. Pre-mix low-heat marine Portland cement, fly ash floating beads, mineral powder, silica fume, metakaolin, nano-silica, and polyaluminum chloride to obtain component B;

[0039] Step 3: First put component A in a concrete mixer and mix for 30 seconds, then add component B and mix for 60 s...

Embodiment 2

[0049] The high-strength coral aggregate concrete is made of the following raw materials in parts by weight: 302 parts of low-heat marine Portland cement, 42 parts of fly ash floating beads, 42 parts of mineral powder, 13 parts of silica fume, 13 parts of metakaolin, 4 parts of nano-silica, 4 parts of polyaluminum chloride, 625 parts of coral reef sand, 940 parts of coral reef, 218 parts of sea water and 8 parts of polycarboxylate high-performance water reducing agent.

[0050] in,

[0051] The coral reef is a natural undisturbed or broken coral reef with a particle size of 5-20 mm; the coral reef sand is a natural undisturbed coral reef sand with a particle size of 4.75 mm or less.

[0052] The nano-silica SiO 2 The content is greater than 99.8%, and the specific surface area is greater than 160000m 2 / kg.

[0053] The specific surface area of the polyaluminum chloride is greater than 180m 2 / kg.

[0054] SiO of the silica fume 2 The content is greater than 92%, and t...

Embodiment 3

[0082] The high-strength coral aggregate concrete is made of the following raw materials in parts by weight: 302 parts of low-heat marine Portland cement, 42 parts of fly ash floating beads, 42 parts of mineral powder, 13 parts of silica fume, 13 parts of metakaolin, 4 parts of nano-silica, 4 parts of polyaluminum chloride, 625 parts of coral reef sand, 940 parts of coral reef, 218 parts of sea water and 2 parts of polycarboxylate high-performance water reducing agent.

[0083] in,

[0084] The coral reef is a natural undisturbed or broken coral reef with a particle size of 5-20 mm; the coral reef sand is a natural undisturbed coral reef sand with a particle size of 4.75 mm or less.

[0085] The nano-silica SiO 2 The content is greater than 99.8%, and the specific surface area is greater than 160000m 2 / kg.

[0086] The specific surface area of the polyaluminum chloride is greater than 180m 2 / kg.

[0087] SiO of the silica fume 2 The content is greater than 92%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com