Machine-made sand C30 pumping concrete and preparation method thereof

A technology for pumping concrete and machine-made sand, applied in the field of concrete, can solve the problems that affect the workability and fluidity of concrete, the machine-made sand has rough particle surface, and cannot be stored stably for a long time, and achieves remarkable economic and ecological benefits. The effect of reducing over-reliance and mining, improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

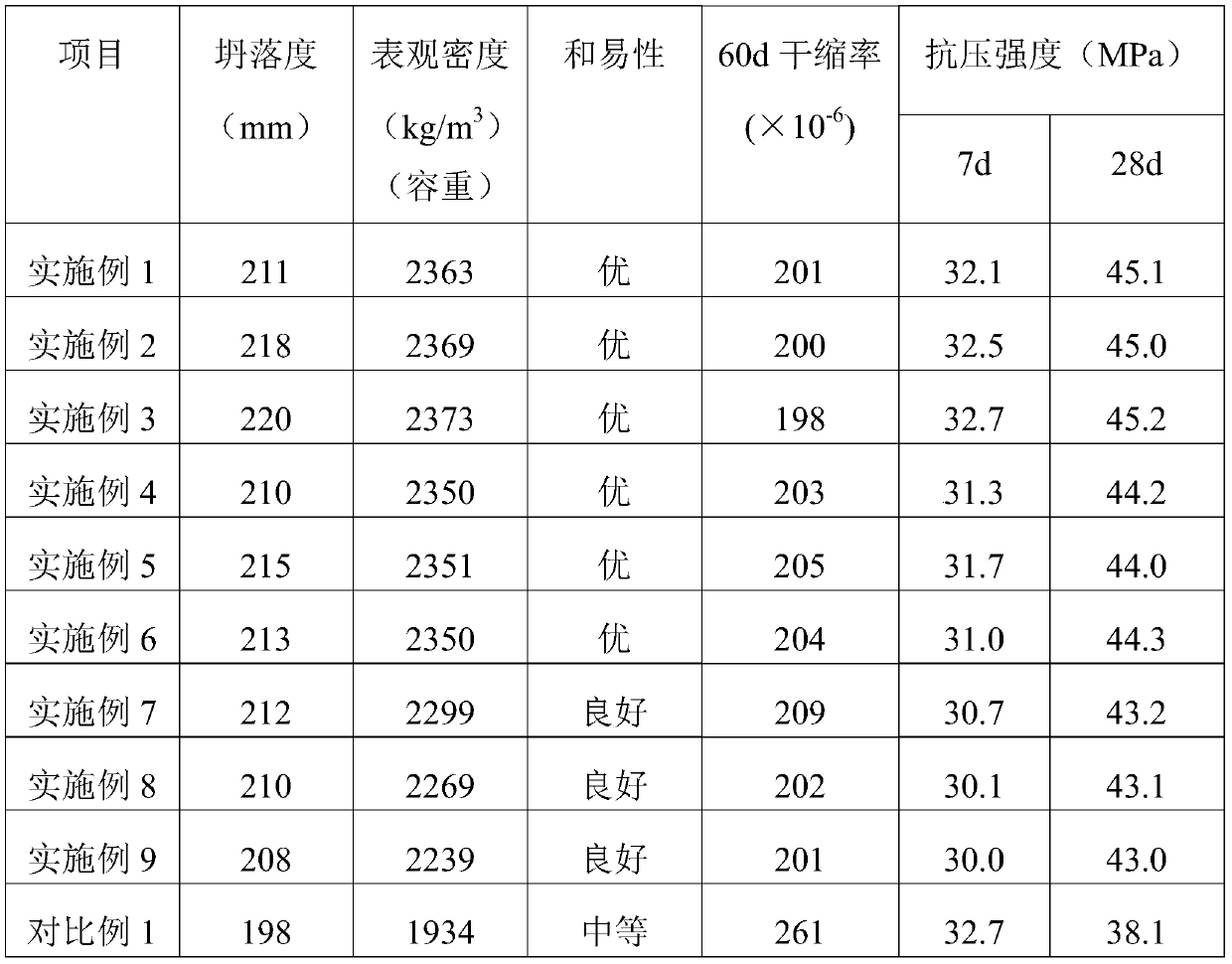

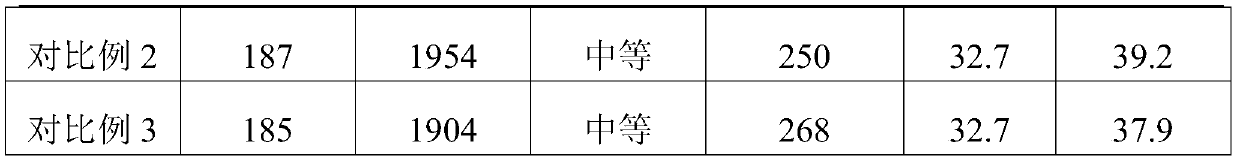

Examples

Embodiment 1

[0023] A machine-made sand C30 pumping concrete, by weight, the preparation of each cubic concrete includes the following weight raw materials: P.O42.5 cement 200kg, fly ash 50kg, water 100kg, machine-made sand 800kg, gravel 900kg, mud embryo 100kg, 8 kg of water reducing agent, 32 kg of rare earth porcelain sand, 10 kg of composite tackifier; the composite tackifier is airgel, hydrogenated rosin resin, and copper fine powder with a mass ratio of 1:1:2.1;

[0024] The fly ash is Class F Class II;

[0025] The water is drinking water;

[0026] The machine-made sand is sand in Zone II with a fineness of 2.3;

[0027] The minimum section size of the gravel is 5mm;

[0028] The water reducer is HN-2000 polycarboxylate high performance water reducer

Embodiment 2

[0030] A machine-made sand C30 pumping concrete, by weight, the preparation of each cubic concrete includes the following weight raw materials: P.O42.5 cement 300kg, fly ash 90kg, water 180kg, machine-made sand 1000kg, gravel 1200kg, mud embryo 200kg, 10kg of water reducing agent, 50kg of rare earth porcelain sand, and 18kg of composite tackifier; the composite tackifier is airgel, hydrogenated rosin resin, and copper fine powder with a mass ratio of 1:3:5;

[0031] The fly ash is Class F Class II;

[0032] The water is drinking water;

[0033] The machine-made sand is sand in Zone II with a fineness of 3;

[0034] The minimum section size of the gravel is 31.5mm;

[0035] The water reducer is HN-2000 polycarboxylate high performance water reducer.

Embodiment 3

[0037] A machine-made sand C30 pumping concrete, by weight, the preparation of each cubic concrete includes the following weight raw materials: P.O42.5 cement 280kg, fly ash 70kg, water 170kg, machine-made sand 912kg, gravel 1000kg, mud embryo 150kg, 9kg of water reducing agent, 40kg of rare earth porcelain sand, 15kg of composite tackifier; the composite tackifier is airgel, hydrogenated rosin resin, and copper fine powder with a mass ratio of 1:2:3.8;

[0038] The fly ash is Class F Class II;

[0039] The water is drinking water;

[0040] The machine-made sand is sand in Zone II with a fineness of 2.8;

[0041] The minimum section size of the gravel is 19mm;

[0042] The water reducer is HN-2000 polycarboxylate high performance water reducer

[0043] The preparation method of the machine-made sand C30 pumping concrete of the above-mentioned embodiments 1-3 comprises the following steps:

[0044] S1. Dissolve the hydrogenated rosin resin and aerogel in an ethanol solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com