Ball head milling cutter abrasion detection system and detection method thereof

A ball-end milling cutter and detection system technology, which is applied in the field of physical measurement, can solve problems such as large software and hardware systems, limited measurement objects, and complicated measurement process, and meet the requirements of reducing the positioning accuracy of repeated installation, and the post-analysis is intuitive and clear, reducing the Dangerous effects of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

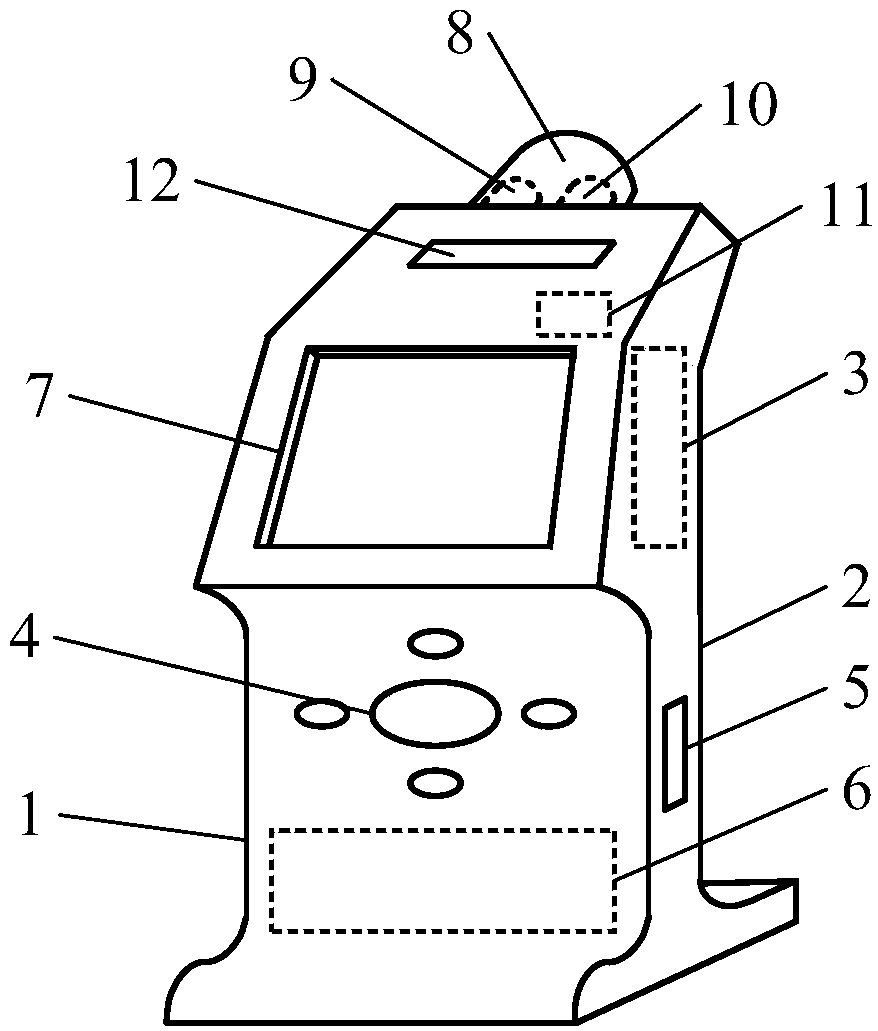

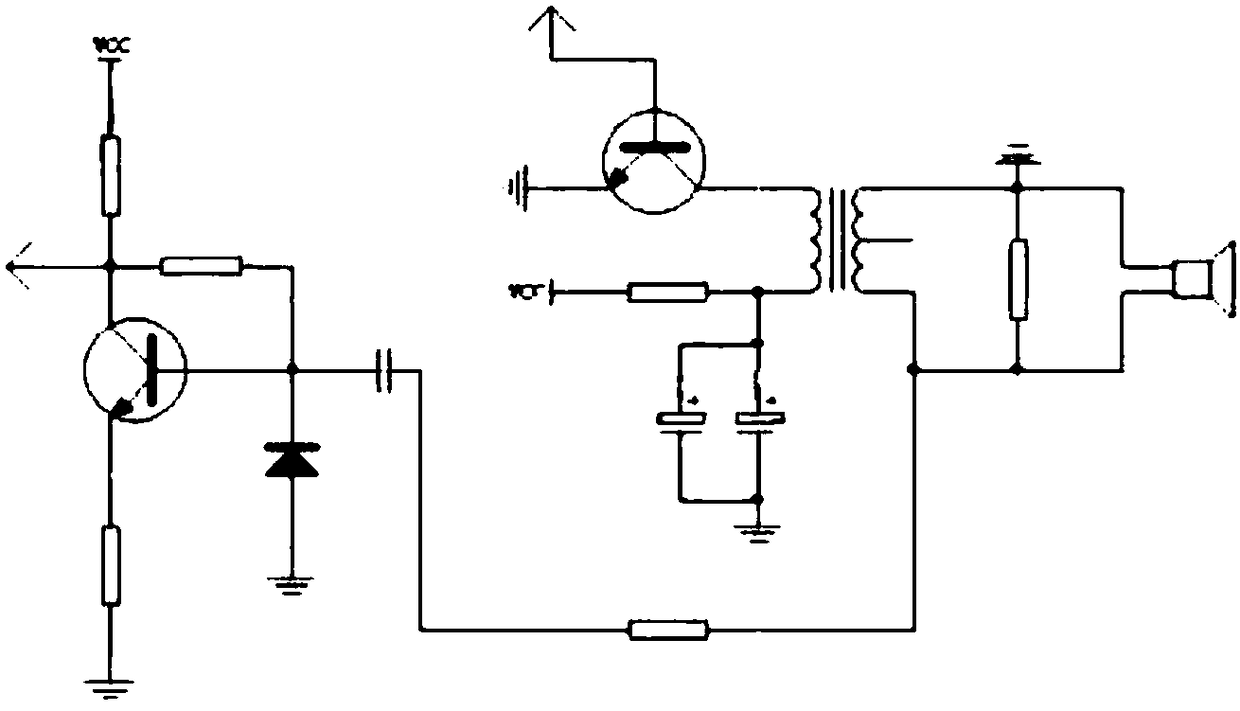

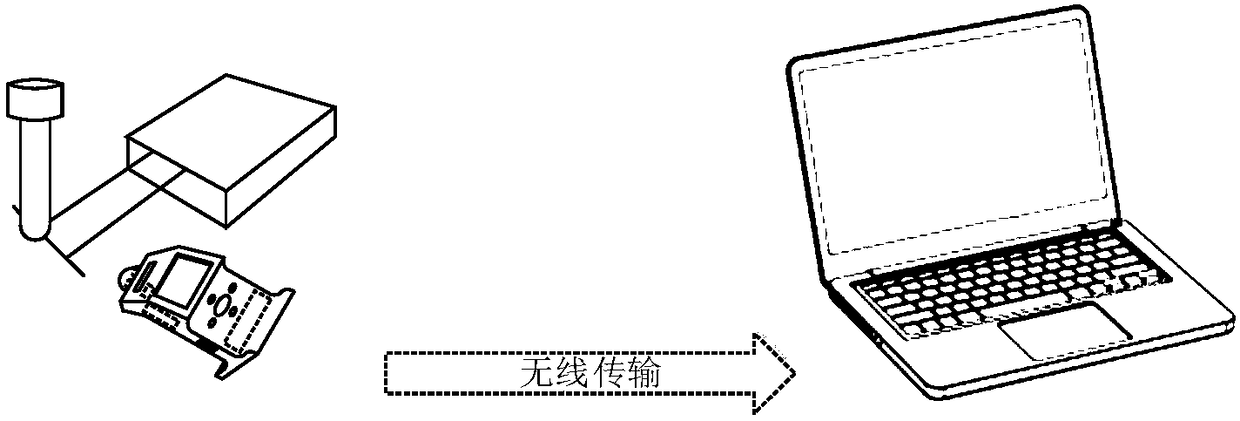

[0022] refer to Figure 1-3 As shown, a ball end milling cutter wear detection system includes a housing 1, a base 2, a circuit board 3, a control room button 4, a data transmission interface 5, a battery compartment 6, a liquid crystal display 7, a detection head 8, and an infrared scanning Head 9, ultrasonic sensor 10, single-chip microcomputer 11 and signal transmitter 12, the liquid crystal display 7 is arranged on the surface of the casing 1, the base 2 is arranged under the casing 1, and the circuit board 3 is arranged in the casing 1 , the circuit board 3 is electrically connected to the liquid crystal display 7, and the base 2 is provided with a data transmission interface 5 and a battery compartment 6. When in use, the measuring head 8 collects data and stores it in the data storage bar. The converted signal is sent by the wireless signal transmitting device 12, and the control button 4 is adjusted so that the circuit board 3 processes and sends the measurement data, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com