Main pump lubricating oil cooler

A technology for pumping lubricating oil and coolers, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

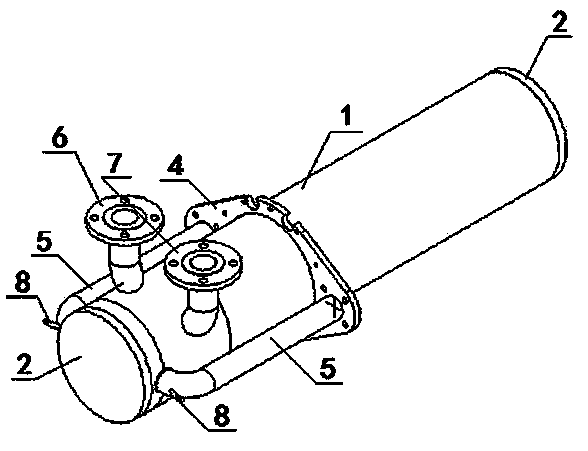

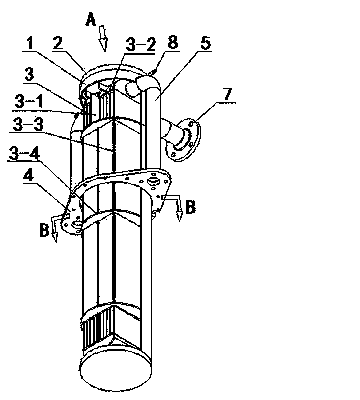

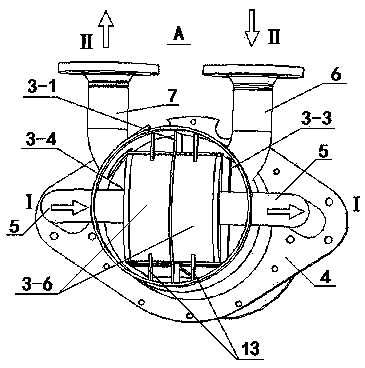

[0029] attached by figure 1 , 2 , 3 and 4 show: the heat exchanger includes cylinder 1, upper and lower end covers 2, plate bundle 3, connecting flange 4, pipeline 5, inlet flange 6, outlet flange 7, wherein cylinder 1 and upper and lower The end cover 2 constitutes the airtight chamber of the heat exchanger, the connecting flange 4 of rhombus structure is arranged in the middle part of the cylinder 1, and the two L-shaped pipelines 5 with drain and oil replenishment ports 8 are arranged symmetrically on the cylinder 1, one end of the pipeline 5 communicates with the cylinder 1, and the other end is arranged on the connecting flange 4, and the inlet flange 6 and the outlet flange 7 are arranged on the cylinder 1 perpendicular to the axial direction of the pipeline 5 , the plate bundle 3 is arranged in the airtight cavity of the cylinder 1 .

[0030] attached by Figure 4 , 5 , shown in 6: the plate bundle 3 is composed of multiple groups of plate butt welding assembly for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com