Wire harness storing device

A storage device and wire harness technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve the problems of reduced work efficiency, disorderly placement of wire harnesses, slow taking efficiency, etc., to improve applicability, avoid The effect of space constraints and easy access to wire harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

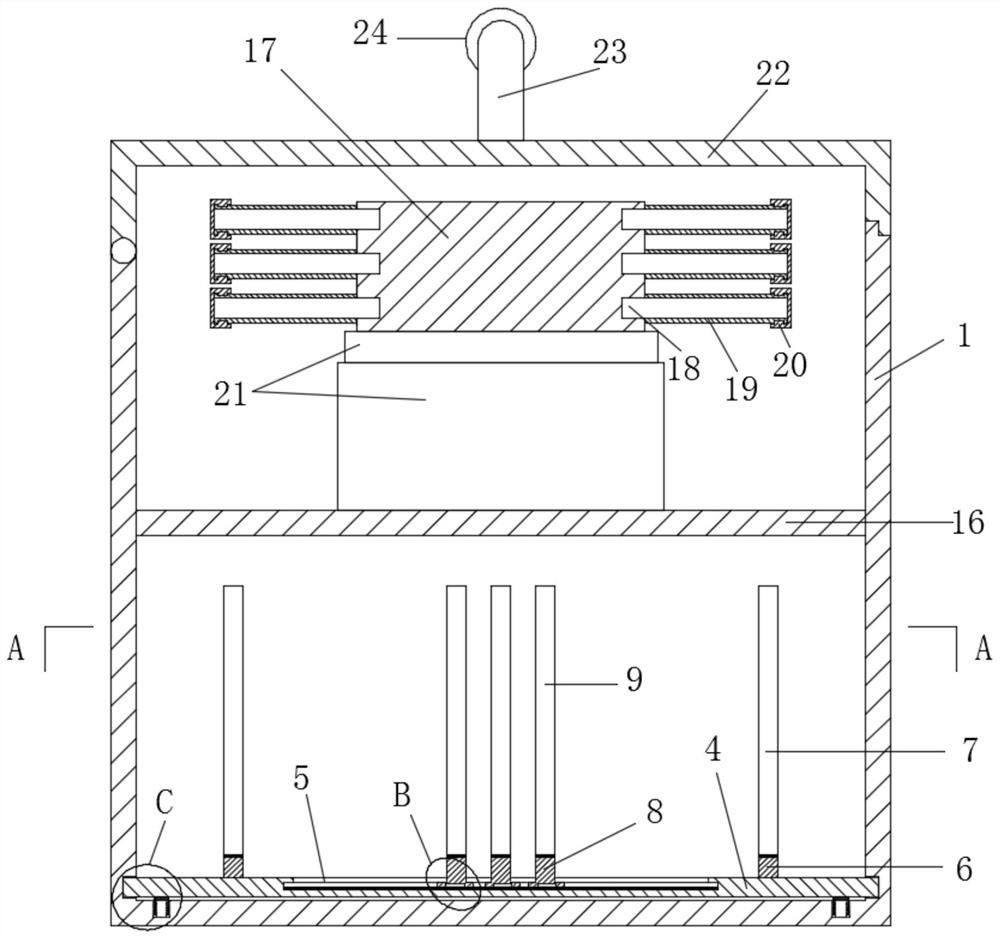

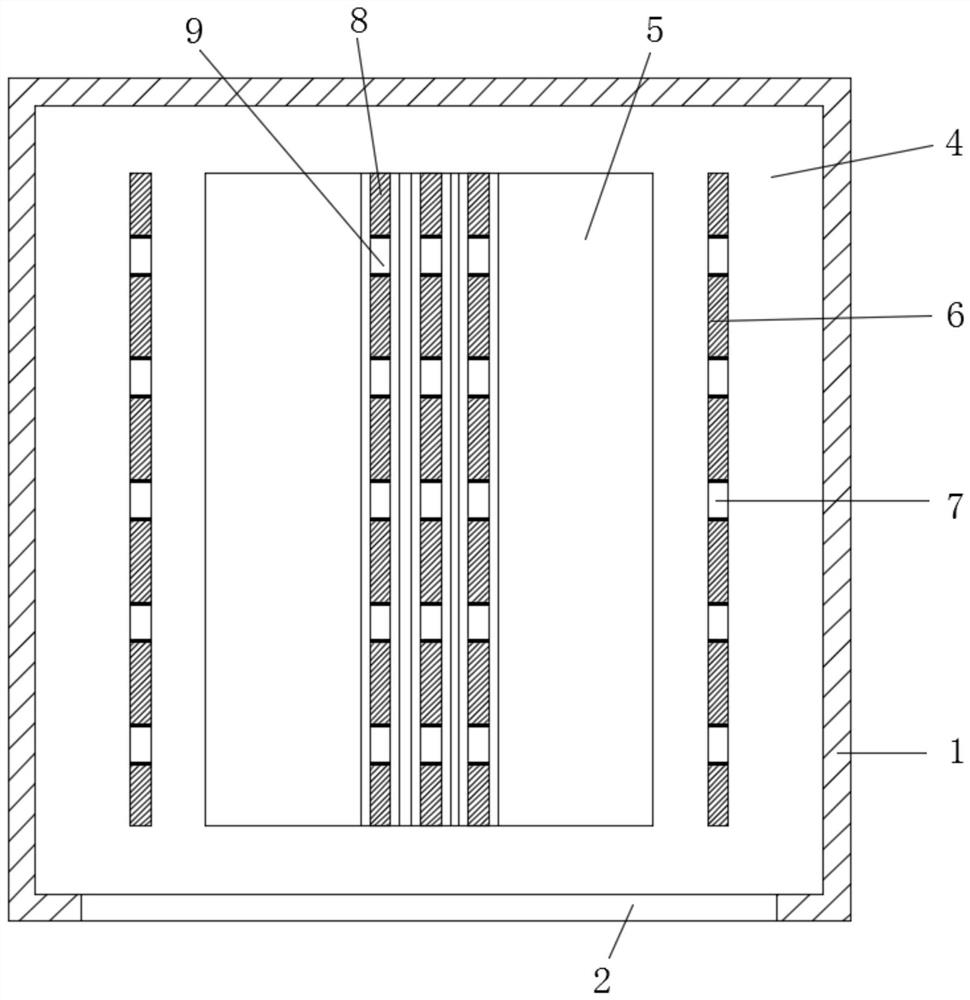

[0024] see Figure 1-6 , a wire harness storage device, including a wire harness storage box 1, the side of the wire harness storage box 1 is provided with a pick-and-place hole 2, and the outer side of the pick-and-place hole 2 is provided with a protective door 3, and the protective door 3 is equipped with The damped rotation is installed on the side of the wire harness storage box 1, the bottom of the wire harness storage box 1 is detachably installed with a wire harness placement assembly, and the wire harness placement assembly includes a mounting plate detachably installed on the wire harness storage box 1 4. The mounting plate 4 is provided with a T-shaped chute 5, and the mounting plate 4 located on both sides of the T-shaped chute 5 is fixedly installed with a fixed placement plate 6, and the fixed placement plate 6 is provided with a number of uniform Placement slots 7 are arranged, and a plurality of T-shaped movable placement plates 8 are installed slidingly with d...

Embodiment 2

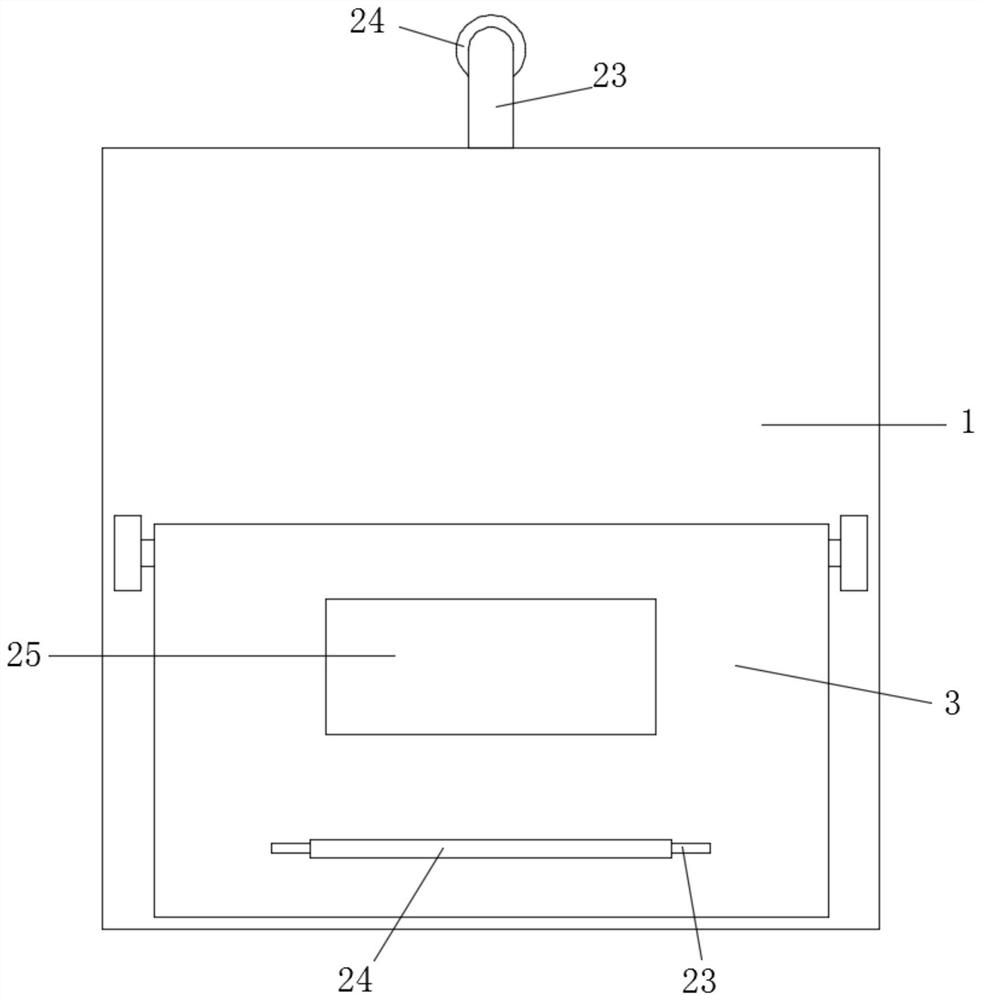

[0032] This embodiment is further improved on the basis of the embodiment. The improvement is that: a label slot 25 is fixedly installed on the protective door 3; The corresponding diameter labels make it easy for people to clearly distinguish the wire harnesses in each wire harness storage box 1, and further improve the storage of the wire harnesses.

[0033] The working principle of this embodiment is: by setting the label groove 25, a diameter label corresponding to the diameter of the wire harness in the wire harness storage box 1 is placed in the label groove 25, so that people can clearly distinguish the wire harness in each wire harness storage box 1, More perfect storage of wiring harness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com