Flue gas purifying equipment of kiln

A flue gas purification and equipment technology, which is applied in gas treatment, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems of harmful substance discharge and low treatment efficiency, and achieves low operating costs, reduced work intensity, and good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

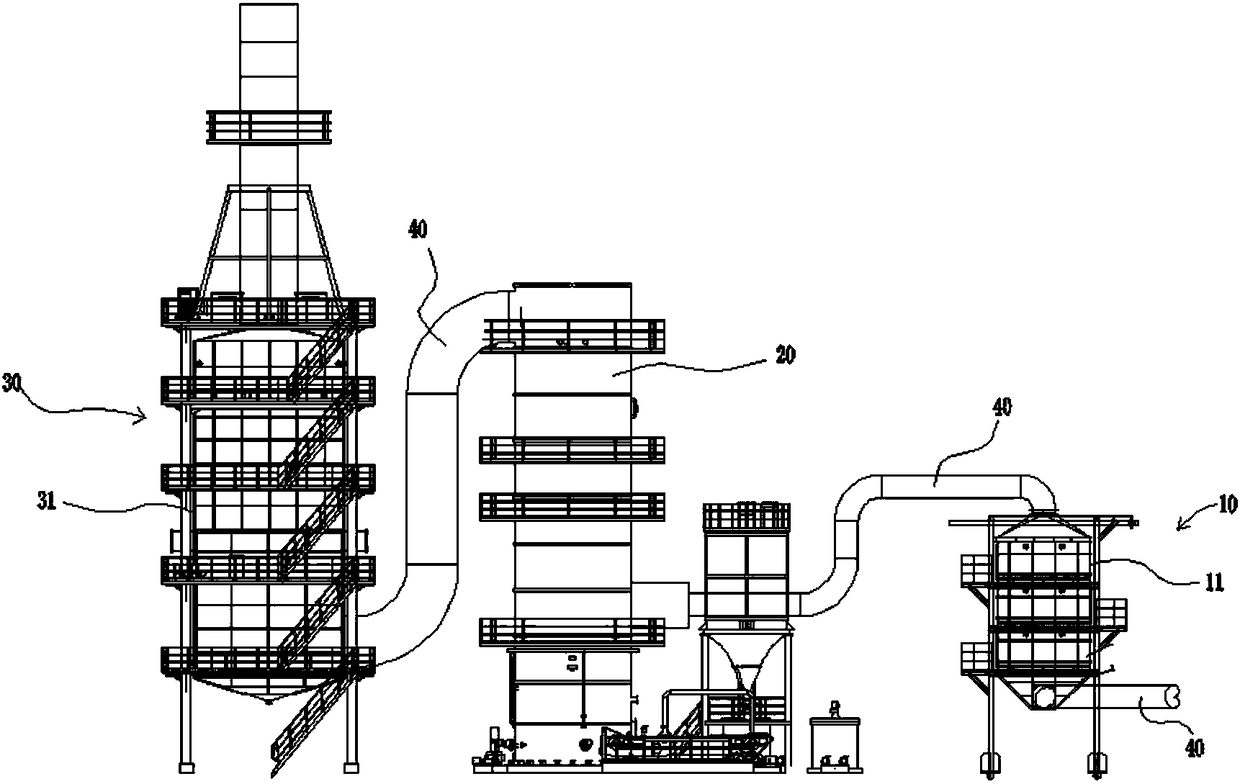

[0012] Such as figure 1 , 2 As shown, the kiln flue gas purification equipment of this embodiment includes low-temperature denitrification equipment 10, desulfurization equipment 20, and wet electrostatic demist and dust removal equipment 30 connected sequentially through the flue gas pipeline 40. The low-temperature denitrification equipment 10 includes a reactor The main body 11, and the reducing agent preparation system 12, the ammonia gas injection device 13 and the catalyst injection device 14 arranged in the reactor body 11, the reducing agent preparation system 12 prepares the reducing agent and mixes it with the flue gas, and the ammonia The gas injection device 13 injects ammonia gas into the flue gas, and the catalyst injection device 14 injects catalyst into the mixed gas of ammonia gas and flue gas; the reactor body 11 is divided into four sections from bottom to top, which are injection Ammonia section 15 , mixing section 16 , flow equalization section 17 and rea...

Embodiment 2

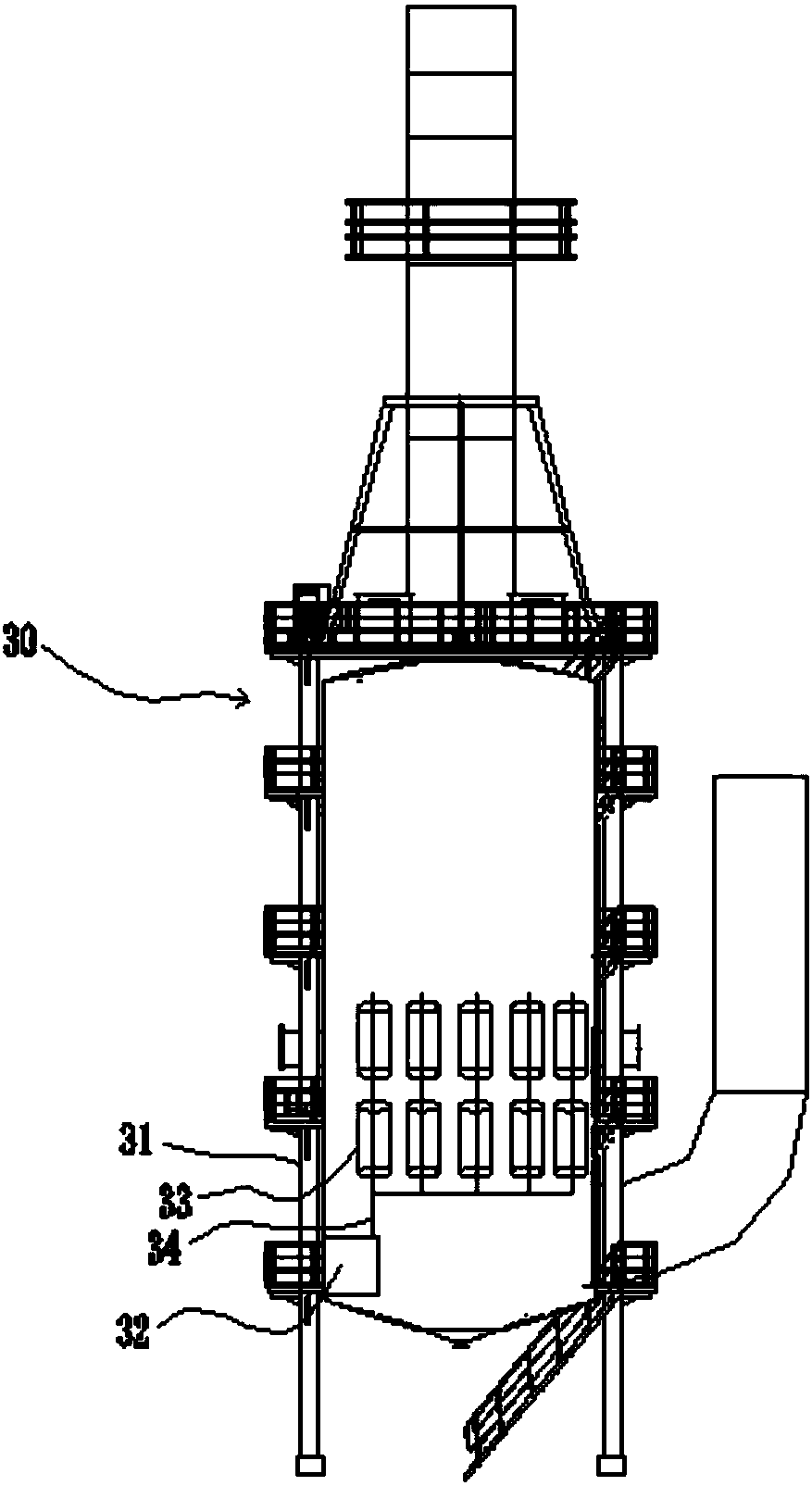

[0018] Such as figure 1 , 2 , 3, the wet electrostatic mist removal and dust removal equipment 30 described in this embodiment includes an electric demister body 31 and a high-voltage electrostatic device 32 arranged in the electric demister 31, and the high-voltage electrostatic device 32 is connected with Several corona wires 34 are respectively inserted into the hollow precipitation tube 33 and are not in contact with the inner wall of the precipitation tube 33 . The working principle is the same as that of the electrostatic precipitator, except that the precipitation electrode adopts a honeycomb tube bundle structure, and each precipitation electrode tube corresponds to a cathode corona wire. During operation, the high-voltage electrostatic device 32 is used to apply negative high-voltage electricity to the corona wire 34 erected in the wet-type electrostatic defogging and dust removal equipment 30, thereby forming an uneven high-voltage electrostatic field between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com