Horizontal reducing atmosphere vacuum annealing furnace

A vacuum annealing furnace and atmosphere technology, which is applied in the field of horizontal reducing atmosphere vacuum annealing furnaces, can solve the problems of poor gas flow control accuracy, difficult to meet the index requirements, low vacuum degree of the atmosphere system, etc., and achieves reduced power consumption and novel structure. , the effect of good control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

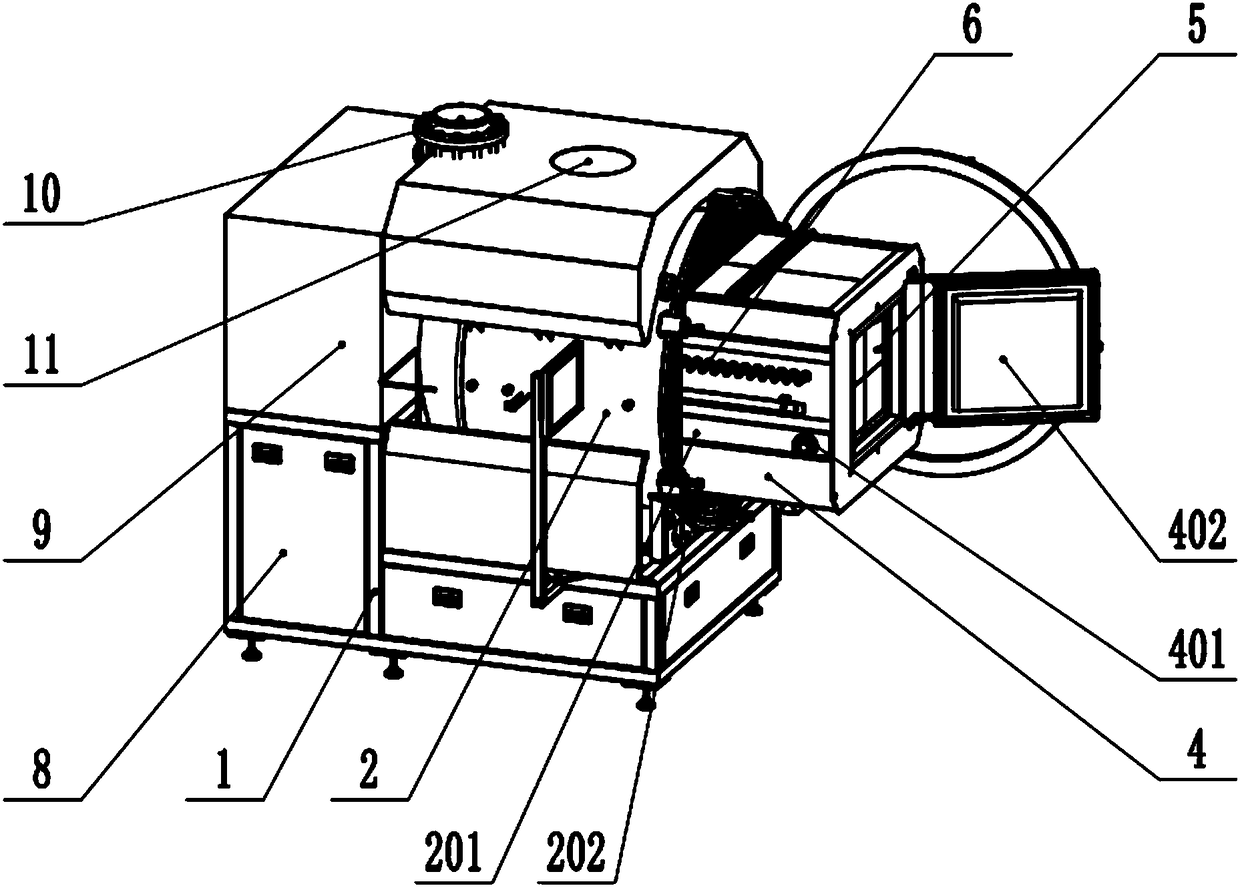

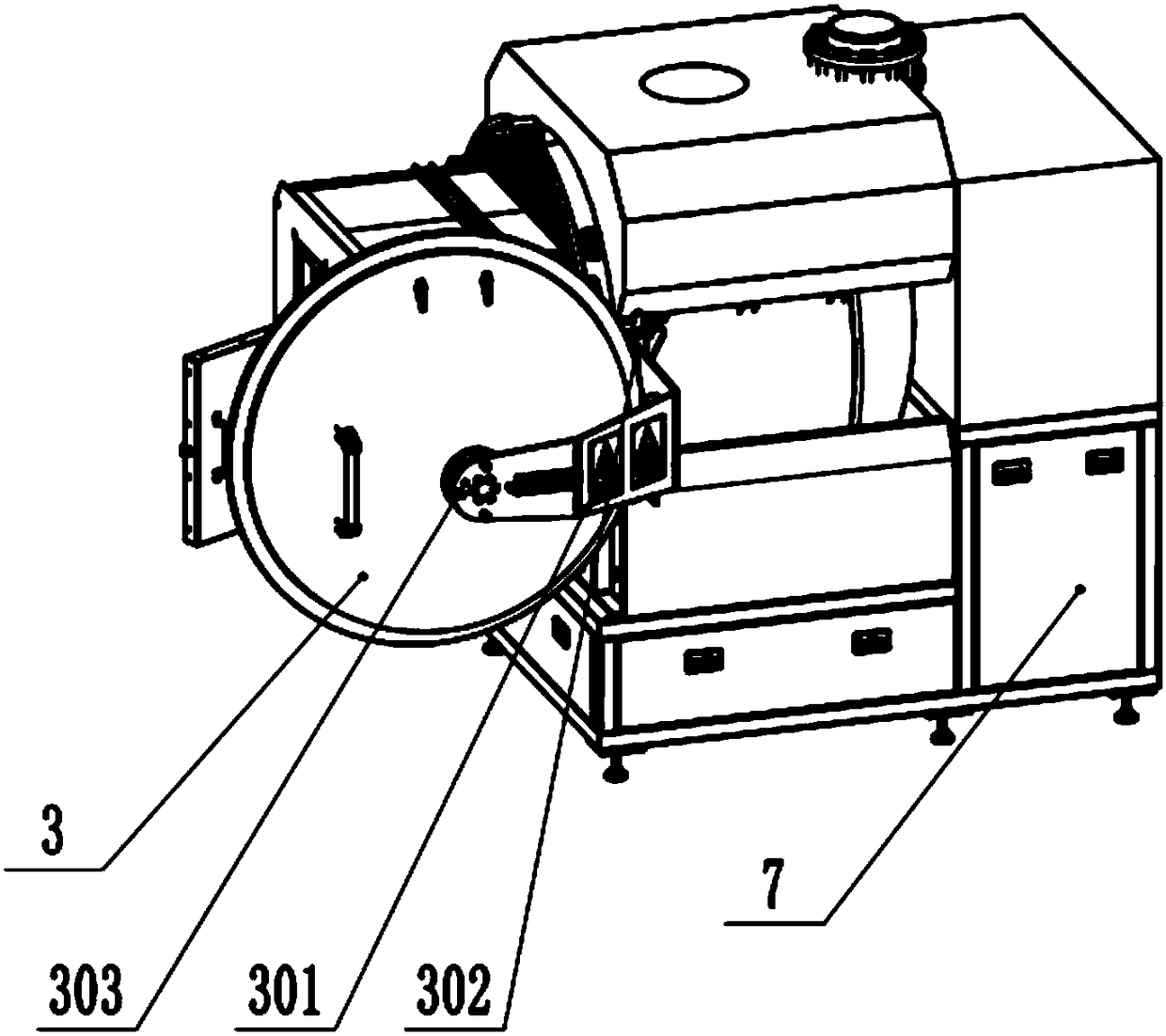

[0020] see Figure 1-2 The invention provides a technical solution: a horizontal reducing atmosphere vacuum annealing furnace, including a frame 1, a furnace body 2, a furnace door 3, a furnace liner 4, a thermal insulation furnace lining 5, a heating element 6, a vacuum system 7, and an atmosphere system 8. Control system 9, safety device 10 and heat dissipation device 11, wherein: the furnace body 2 is installed on the frame 1, the furnace door 3 is connected to the furnace body 2, the furnace gall 4 is placed inside the furnace body 2, and the heat-insulating furnace lining 5 is installed Inside the furnace 4, the heating element 6 is arranged and installed on both sides of the heat-insulating furnace lining 5, the vacuum system 7 and the atmosphere system 8 are installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com