Power plant circulating cooling water waste water treatment method and system

A technology for wastewater treatment system and circulating cooling water, which is applied in the fields of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can improve the recycling rate and application range, reduce the content of sulfate radicals, and reduce the content of high-value salts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

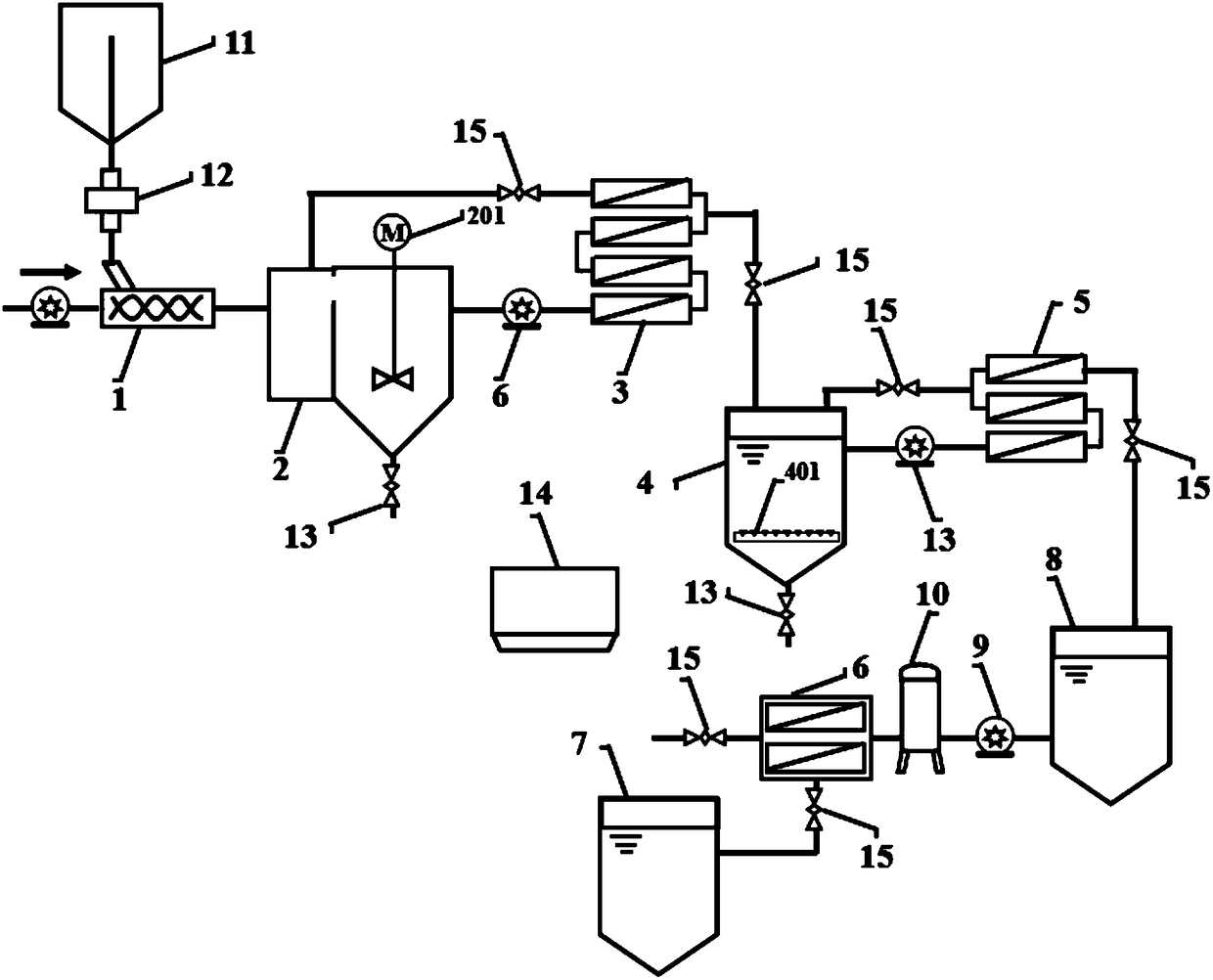

[0028] Such as figure 1 , the embodiment of the present invention provides a kind of power plant circulating cooling water wastewater treatment method, comprising:

[0029] Step 1, adding sodium aluminate and calcium-containing substances to the wastewater, so that the sodium aluminate, the calcium-containing substances and the sulfate in the wastewater undergo a complex reaction to form a complex sulfate precipitate, wherein the The calcium-containing substance is calcium oxide or calcium hydroxide; in the present embodiment, the sodium aluminate and the calcium-containing substance added are preferably solution properties, and the calcium-containing substance is preferably calcium hydroxide solution; wherein, complexing The reaction can be represented by the following formula:

[0030] SO 4 2- +Ca 2+ +AlO 2 - +OH - →3CaO·Al 2 o 3 · 3CaSO 4 ↓(ettringite)

[0031] In step 2, the clear liquid obtained from the complexation reaction in step 1 is processed by pre-stage...

Embodiment 2

[0041] Such as figure 1 The embodiment of the present invention relates to a wastewater treatment system for circulating cooling water in a power plant, which includes a complexation reaction tank 2, a pre-stage membrane filter mechanism 3, an aeration reaction tank 4, a rear-stage membrane filter mechanism 6 and Clear water collection tank 7, wherein, the waste water inlet of described aeration reaction tank 4 is communicated with the fresh water outlet of described pre-stage membrane filter mechanism 3, and described clear water collection tank 7 is communicated with the fresh water outlet of described rear stage membrane filter mechanism 6 ; The complexation reaction tank 2 is provided with an agitator 201, and the aeration reaction tank 4 is provided with an aeration device 401.

[0042] The above-mentioned complexation reaction pool 2 is connected with a sodium aluminate adding mechanism and a calcium-containing substance adding mechanism, which facilitates adding sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com