A kind of preparation method of tetrabromophthalic anhydride

A technology of tetrabromophthalic anhydride and phthalic anhydride, applied in the field of preparation of tetrabromophthalic anhydride, can solve problems such as increased production cost, high sulfate radical content, large bromine consumption, etc., and achieves low consumption, low sulfate radical content, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

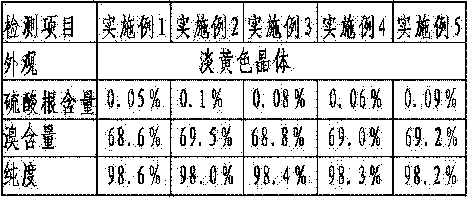

Examples

Embodiment 1

[0023] A preparation method for tetrabromophthalic anhydride, comprising the following steps:

[0024] 1) Put phthalic anhydride into a reaction kettle with 65% oleum at a temperature of 20°C, then add aluminum powder, and then add bromine dropwise, wherein the weight ratio of phthalic anhydride, oleum, aluminum powder, and bromine is The ratio is 1:7:0.01:2.3, the bromine addition time is controlled at 4h, after the bromine addition is completed, the temperature is raised to 60°C, and the reaction is 7h;

[0025] 2) Vacuumize the reactor for 2 hours, then raise the temperature to 90°C and react for 5 hours. After the reaction, lower the temperature to 30°C and carry out suction filtration;

[0026] 3) Add purified water to the material after suction filtration and stir and wash. The amount of water added is twice the mass of the material after suction filtration. The washing temperature is 60°C. The number of washing times is 3 times. When the value is 6, it is a qualified p...

Embodiment 2

[0029] A preparation method for tetrabromophthalic anhydride, comprising the following steps:

[0030] 1) Put phthalic anhydride into a reaction kettle with 40% oleum at a temperature of 30°C, then add iron powder, and then add bromine dropwise, wherein the weight ratio of phthalic anhydride, oleum, iron powder, and bromine The ratio is 1:8:0.03:3, the bromine addition time is controlled at 5h, after the bromine addition is completed, the temperature is raised to 70°C, and the reaction is 5h;

[0031] 2) Vacuumize the reactor for 5 hours, then raise the temperature to 110°C, react for 3 hours, after the reaction, lower the temperature to 40°C, and carry out suction filtration;

[0032] 3) The material after suction filtration is stirred and washed with pure water, the amount of water added is 3 times the mass of the material after suction filtration, the washing temperature is 80°C, the number of washings is 2 times, and the time of each washing is 2 hours. The pH of the water...

Embodiment 3

[0035] A preparation method for tetrabromophthalic anhydride, comprising the following steps:

[0036] 1) Put phthalic anhydride into a reaction kettle with 52% oleum at a temperature of 25°C, then add aluminum trichloride, and then add bromine dropwise, among which phthalic anhydride, oleum, aluminum trichloride, bromine The weight ratio of bromine is 1:7.5:0.02:2.65, the bromine dropping time is controlled at 4.5h, after the bromine dropping is completed, the temperature is raised to 65°C, and the reaction is 6h;

[0037] 2) Vacuumize the reactor for 3.5 hours, then raise the temperature to 100°C and react for 4 hours. After the reaction, lower the temperature to 35°C and carry out suction filtration;

[0038] 3) The material after suction filtration is washed with pure water, the amount of water added is 2.5 times of the mass of the material after suction filtration, the washing temperature is 70°C, the number of washing times is 2 times, and the washing time is 2 hours eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com