Preparation method and application for morphology-controlled CdSe-modified porous TiO2 material

A shape and cone technology, applied in the field of nanomaterials, can solve the problem of high recombination rate of photogenerated electrons and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

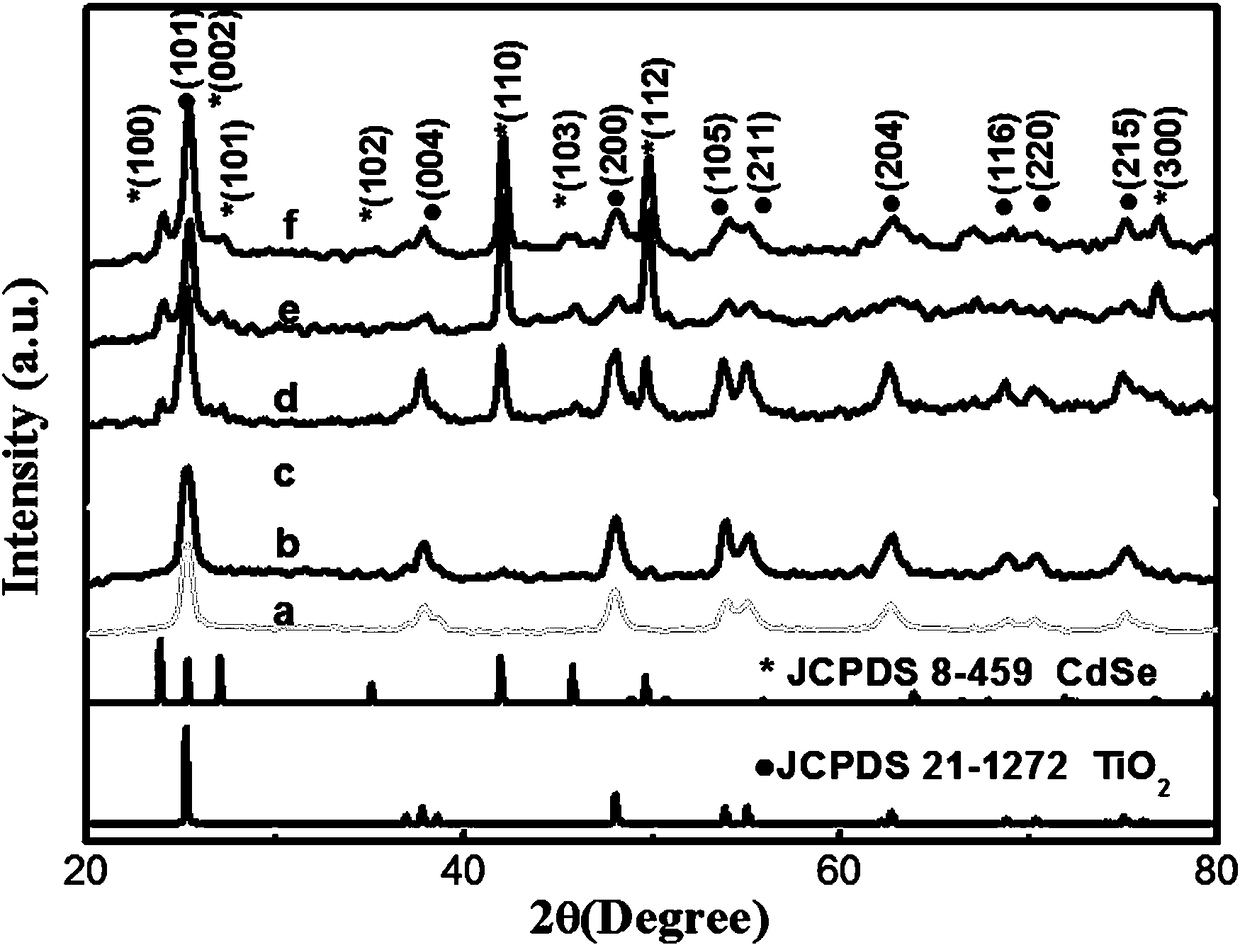

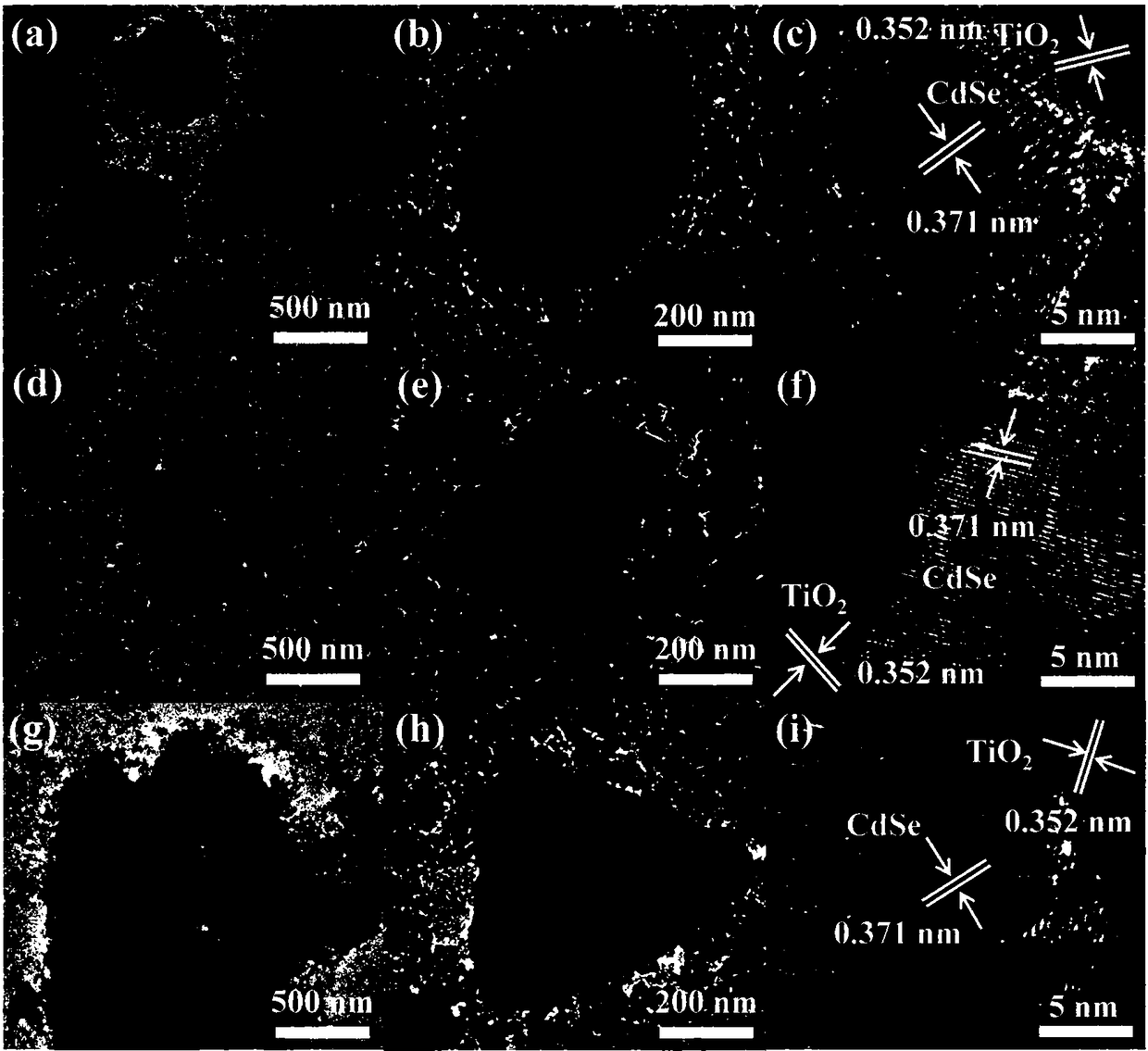

[0044] A kind of preparation method of the CdSe modified porous TiO2 material with controllable morphology, comprising the steps:

[0045] Step 1: Synthesizing monodisperse polystyrene microspheres (PS) with an average diameter of 500 nm;

[0046] Step 2: Preparation of CdO-TiO 2 Intermediate: Using the polystyrene microspheres obtained in step 1) as a template, CdO-TiO was prepared by sol-gel method 2 Intermediate; The sol-gel method prepares CdO-TiO 2 The preparation steps of the intermediate are as follows:

[0047] 1) Put 0.75mLTBOT into 5mL of absolute ethanol, and then magnetically stir at room temperature for 1h to obtain a butyl titanate solution, which is designated as solution A;

[0048] 2) Add 5mL of absolute ethanol to the mixture solution containing 0.5mL of glacial acetic acid and 0.75mL of deionized water, and record it as solution B;

[0049] 3) Then slowly add solution B into solution A, and stir vigorously for 1 hour to obtain a uniform sol-gel;

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com