Spraying-use chocolate in crisp cones and application thereof

A chocolate and crisp tube technology, applied in application, cocoa, frozen desserts and other directions, can solve the problems of poor spraying effect of chocolate spraying, need to strengthen spraying chocolate, difficult control of cost and taste, and achieve good product taste and taste and spraying effect. Good, glossy finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

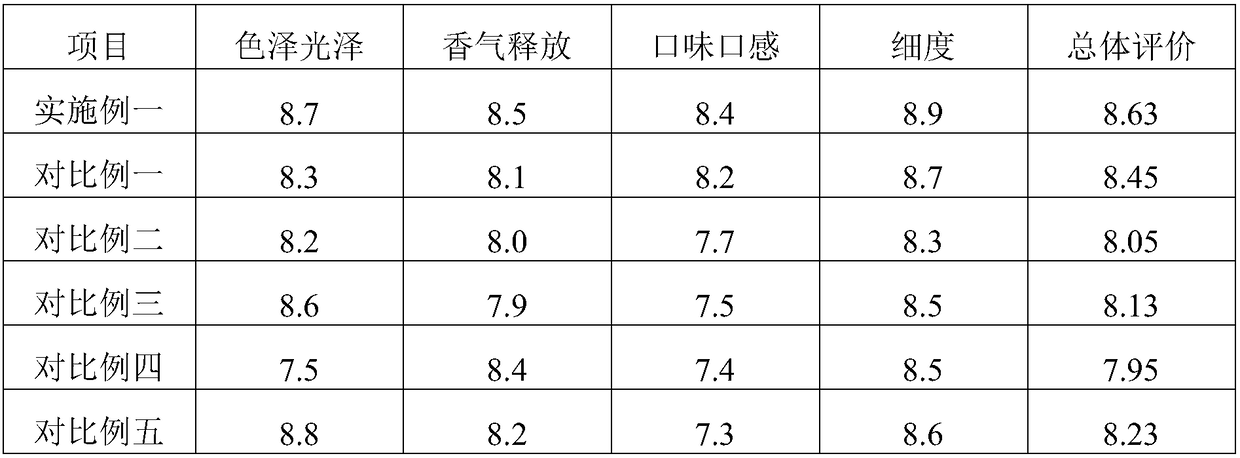

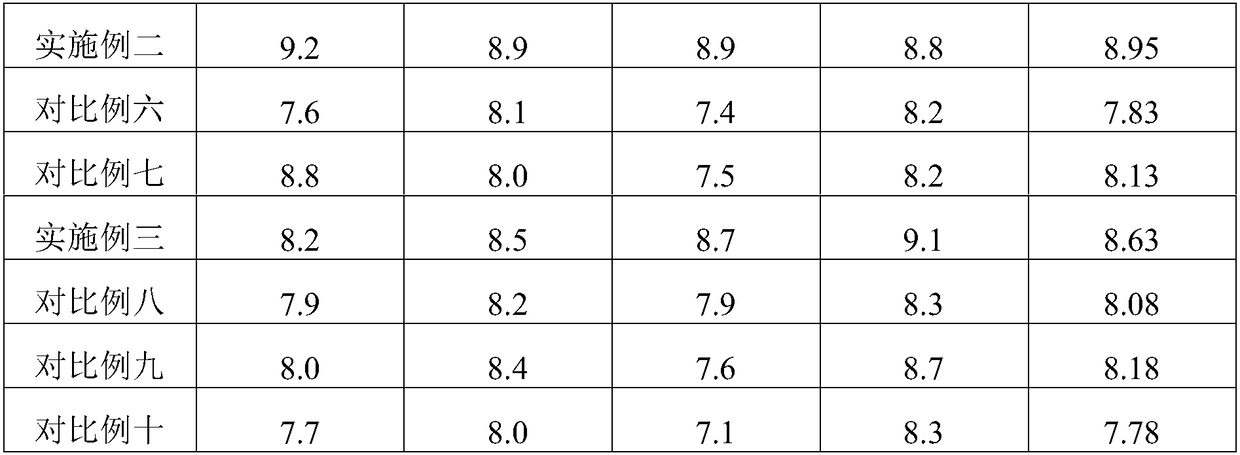

Examples

Embodiment 1

[0035] Prepare 1000kg of chocolate for spraying in crispy tube frozen drinks, the raw material formula used is as follows:

[0036] White sugar: 430kg Coconut oil: 310kg Palm oil: 165kg Low-fat cocoa powder: 90kg

[0037] Emulsifier: Lecithin 4kg

[0038] Edible flavors and fragrances: 1kg

[0039] The production process of the preparation process is as follows:

[0040] Standardization of raw materials → mixing of raw materials → pre-refining → fine grinding → refining → sieving → heat preservation for use

[0041] Raw material inspection: must pass sensory, physical and chemical inspection, microbiological test, no adulteration and other foreign matter; meet the relevant national or industry standards for raw materials.

[0042] Raw material pretreatment: Edible oil and fat raw materials (coconut oil, palm oil) are preheated and melted (temperature <60°C) for later use; white granulated sugar is crushed and ground into powder for later use.

[0043] Mixing of raw materia...

Embodiment 2

[0051] Prepare 1000kg of chocolate for spraying in crispy tube frozen drinks, the raw material formula used is as follows:

[0052]White sugar: 400kg Coconut oil: 310kg Corn oil: 165kg Medium-fat cocoa powder: 120kg

[0053] Emulsifier: ammonium phospholipid 4kg

[0054] Edible flavors and fragrances: 1kg

[0055] Preparation process The production process is the same as that in Example 1.

[0056] According to the chocolate formula provided in this example, through the above production process (same as Example 1), a brown color with bright color, natural and strong cocoa aroma, soft taste, moderate viscosity, strong fluidity and glossy surface can be obtained. Spray the chocolate mixture. The prepared chocolate is sprayed inside the crisp tube, the chocolate is evenly dispersed on the inner wall of the crisp tube and the inner wall of the paper sleeve on the upper edge of the crisp tube, and the crisp tube is completely sealed to ensure the crispness of the crisp tube. The...

Embodiment 3

[0058] Prepare 1000kg of chocolate for spraying in crispy tube frozen drinks, the raw material formula used is as follows:

[0059] White sugar: 430kg soybean oil: 340kg cocoa butter: 165kg high-fat cocoa powder: 60kg

[0060] Emulsifier: polyglyceryl ricinoleate 4kg

[0061] Edible flavors and fragrances: 1kg

[0062] Preparation process The production process is the same as that in Example 1.

[0063] According to the chocolate formula provided in this example, through the above-mentioned production process (same as Example 1), a kind of chocolate with bright color, natural rich cocoa aroma and slightly burnt taste, moderate viscosity, strong fluidity and glossy surface can be obtained. Brown-gray spray chocolate. The prepared chocolate is sprayed inside the crisp tube, the chocolate is evenly dispersed on the inner wall of the crisp tube and the inner wall of the paper sleeve on the upper edge of the crisp tube, and the crisp tube is completely sealed to ensure the crisp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com