Pixel driving structure and method of OLED display device

A technology for driving structures and display devices, applied in static indicators, instruments, etc., can solve the problems of increasing chip power consumption and cost, increasing power consumption and area, and decreasing product economy, and achieves control of product cost, large size, etc. The effect of drive capability, high display resolution and picture refresh rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

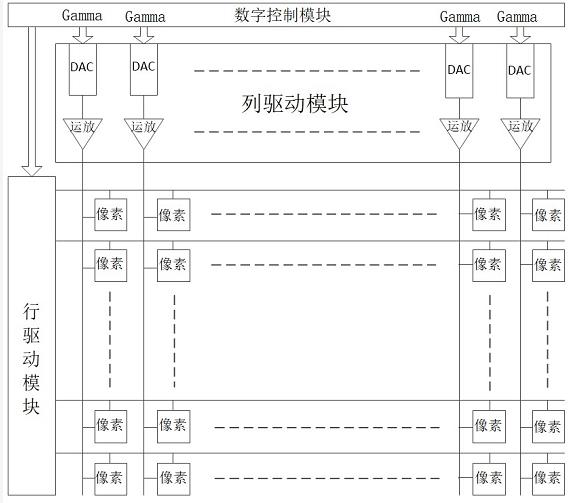

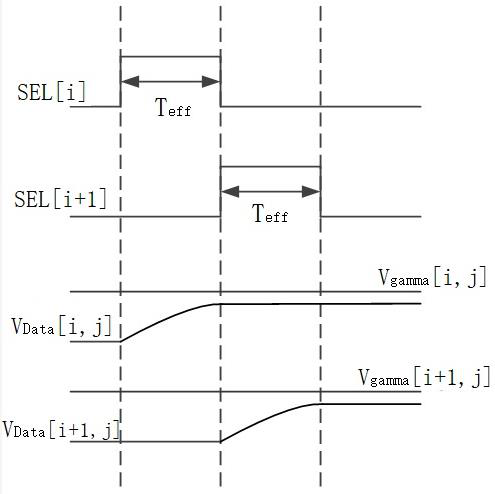

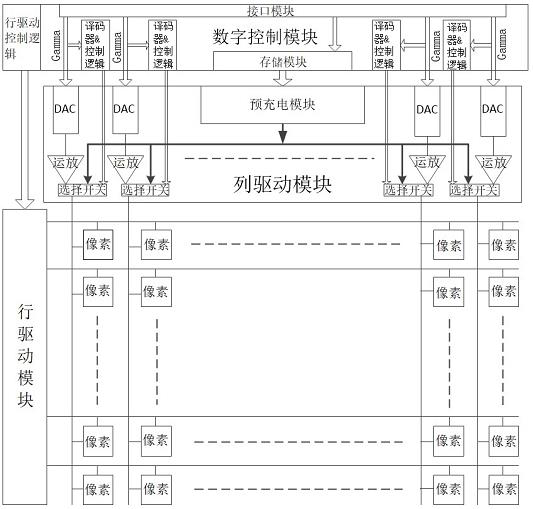

[0035] The pixel drive structure of this embodiment, such as image 3 As shown, it mainly includes a digital control module, a column driver module, a row driver module and a pixel array, where:

[0036] The digital control module mainly includes an interface module, a storage module, a decoder, control logic, and row drive control logic. The interface module is electrically connected to the external device, the column driver module, the storage module, the decoder and the control logic, and is used to transmit the image grayscale digital data (Gamma, which is a digital binary code) in the external device to the decoder and control logic and column driver blocks. The storage module includes a register, and the external device reads and writes the register through the interface module to adjust the value of the register. The number of decoders and control logic is the same as the number of columns of the pixel array. The row driving control logic is electrically connected to...

Embodiment 2

[0055] The pixel driving structure of this embodiment is as follows image 3 As shown, the difference from Embodiment 1 is that in this embodiment, the pre-charging module does not use the voltage division mode, but is designed as Figure 9The structure shown is mainly composed of n pairs of digital-to-analog converters and pre-driver operational amplifiers (n is an integer greater than or equal to 1, which can be set as required). The input end of each digital-to-analog converter is electrically connected to a register in the storage module, and the output end is electrically connected to the input end of the pre-driving operational amplifier. The output terminal of each pre-driver operational amplifier is electrically connected with each selection switch.

[0056] When driving a pixel, see Figure 9 As shown, the values of n registers stored in the storage module in the digital control module are respectively converted into analog voltage values by n DACs in the pre-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com