Iron-fortified recombinant dried egg and preparation method thereof

A dried and dried egg technology, which is applied in the field of iron-enhanced recombinant dried egg and its preparation, can solve the problems of wasting resources, polluting the environment, and failing to obtain high-value utilization of pig blood, and achieves improved gel performance, excellent taste, Realize the effect of efficient value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

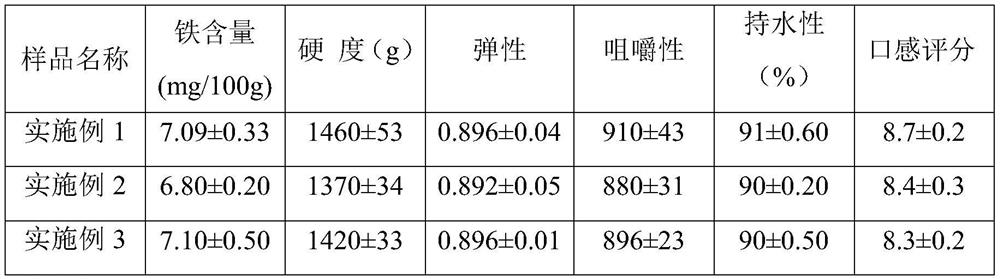

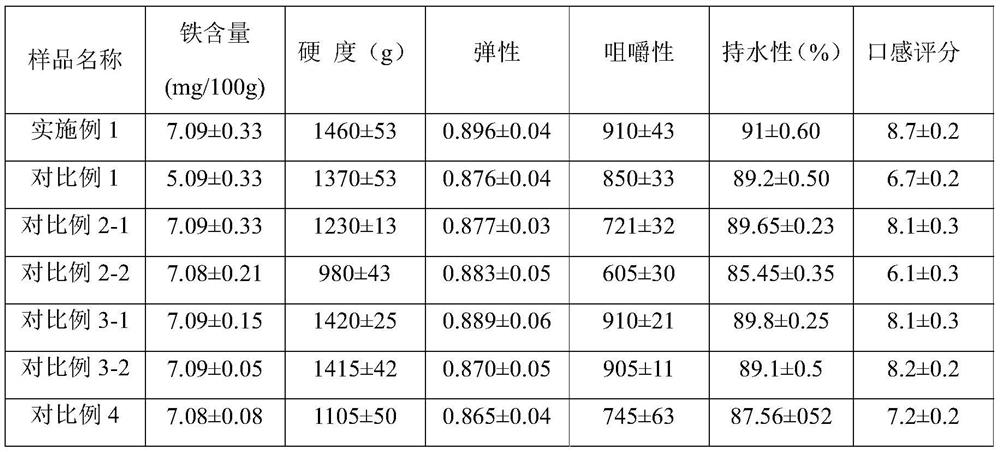

Embodiment 1

[0042] Embodiment 1. A method for preparing iron-enhanced recombinant dried egg, the following steps are carried out in sequence:

[0043] 1), ingredients:

[0044] Select fresh, non-cracked eggs, wash the surface and dry, then separate the shell liquid, separate the egg yolk and egg white with an egg separator, and filter the egg white with a conventional double-layer gauze to remove laces and sundries; use a mixer to mix the egg yolk evenly (Mix at 950rpm / min~1100rpm / min for 1~3 minutes).

[0045] Select fresh pig blood, put it into a container, and use a high-speed shearer to break the wall at a speed of 14000rpm / min to 15000rpm / min for 15 minutes. After the processed pig blood is filtered to remove foam, place it at -20~- Freeze in a refrigerator at 40°C for 24h; freeze-dry the frozen pig blood for 48h (freeze-drying conditions: -50~-60°C, vacuum degree of 1.6~2Pa), take it out and use a high-speed pulverizer to make powder (over 200 purpose sieve);

[0046]Weigh 0.4 pa...

Embodiment 2

[0054] Embodiment 2, with respect to embodiment 1, make the following changes:

[0055] step 1):

[0056] The wall-breaking treatment time of pig blood was changed from 15 minutes to 10 minutes, and the freeze-drying time was changed from 48 hours to 50 hours;

[0057] The preparation method of flavoring seasoning liquid is changed into:

[0058] Weigh 0.3 part of edible white sugar, 0.5 part of dark soy sauce, 0.5 part of light soy sauce, 0.04 part of disodium nucleotide, 0.05 part of ginger powder, 0.05 part of pepper powder, 0.05 part of star anise powder, 20 parts of water , put into the cooking pot and keep boiling for 1h after boiling, the reduced water is replenished according to the original amount, cooled and filtered to obtain the flavoring and seasoning liquid.

[0059] According to the mass ratio of 4:6:0.15:0.01:0.15:1.5, accurately weigh egg white liquid, egg yolk liquid, pig blood powder, gellan gum, NaCl, flavoring and seasoning liquid to obtain the prepared ...

Embodiment 3

[0063] Embodiment 3, with respect to embodiment 1, make the following changes:

[0064] step 1):

[0065] The wall-breaking treatment time of pig blood was changed from 15 minutes to 20 minutes, and the freeze-drying time was changed from 48 hours to 45 hours;

[0066] The preparation method of flavoring seasoning liquid is changed into:

[0067] Weigh 0.5 parts of edible white sugar, 0.4 parts of dark soy sauce, 0.3 parts of light soy sauce, 0.05 parts of flavored nucleotide disodium, 0.03 parts of ginger powder, 0.06 parts of pepper powder, 0.06 parts of star anise powder, 0.1 part of chili powder, 15 parts of water, put into the cooking pot and keep boiling for 1h after boiling, the reduced water is replenished according to the original amount, and the seasoning liquid is obtained after cooling and filtering.

[0068] According to the mass ratio of 3.5:6.8:0.2:0.015:0.1:1, accurately weigh egg white liquid, egg yolk liquid, pig blood powder, gellan gum, NaCl, flavoring an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com