Carbon-coated ternary material and preparation method thereof

A ternary material and carbon-coated technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of difficult operation and tediousness, and achieve the effects of reducing dissolution, good electronic conductivity, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

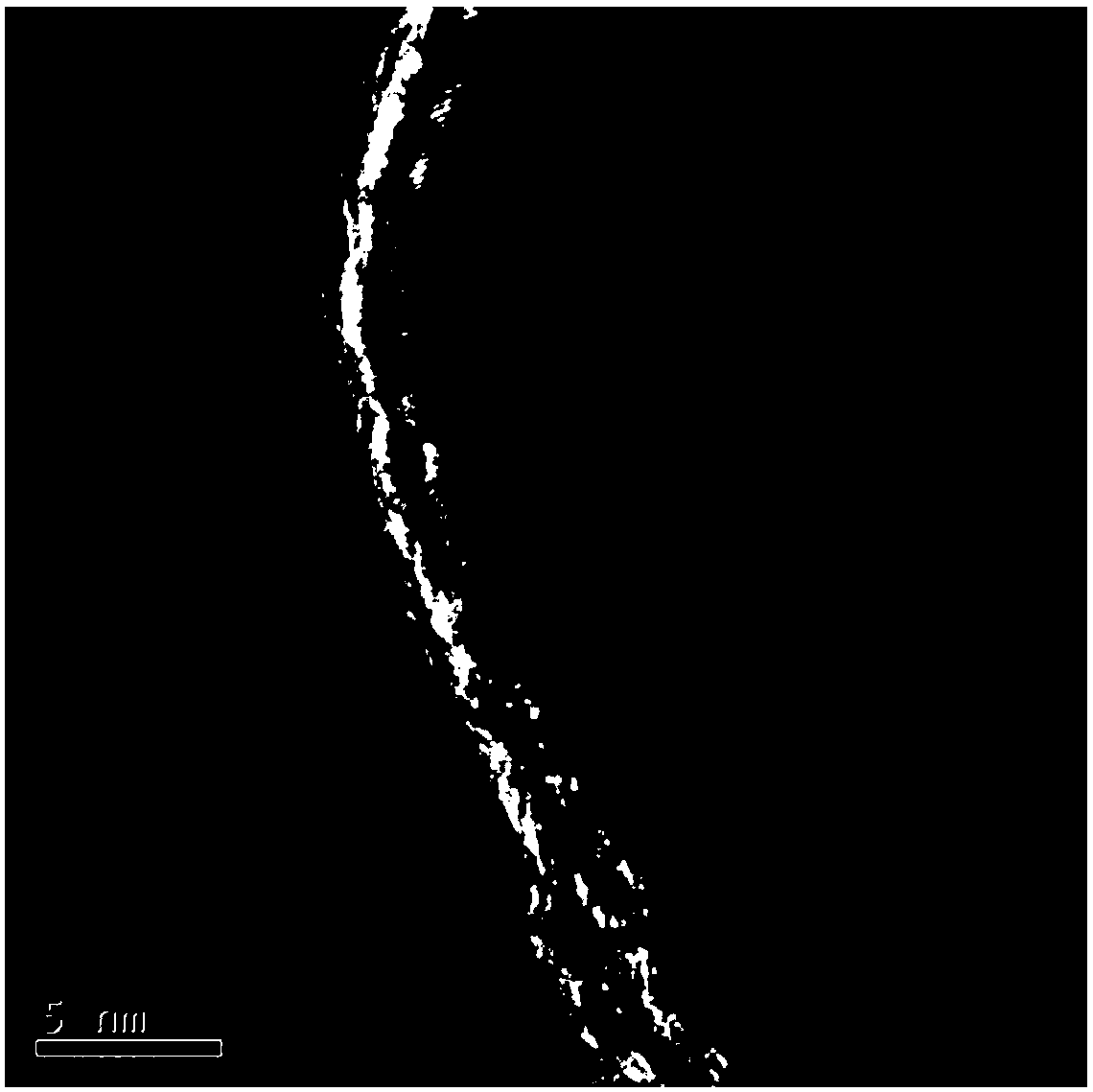

[0035] The embodiment of the present invention proposes a carbon-coated ternary material preparation method, including:

[0036] adding the ternary material into the ball milling equipment, the ball milling equipment includes ball milling beads, the inner wall of the ball milling equipment and / or the ball milling beads are attached with carbon material, the ball milling is performed at a second rotational speed, and the milling time is the second time length;

[0037] The above operation is repeated many times, so that the ternary material contains 0.2-2% by weight of carbon material.

[0038] In this embodiment, a certain mass of ternary positive electrode material is put into a ball mill that has just milled carbon materials, and the ball mill is turned on at the second rotational speed. After the second time of ball milling, a small amount of carbon material can be obtained at this time. Ternary material. The general formula of the above-mentioned ternary cathode material ...

Embodiment 1

[0053] Step 1. Put 5g of artificial graphite into the ball milling equipment. For example, QM3-SP4 planetary ball mill can be used. The lining of the ball mill is made of ceramic material for metal isolation treatment, and ball milling beads made of zirconia are used. The ball milling beads can be 5mm or 1mm. The mass ratio of ball milling beads of different particle sizes is 1:1, and the ball-material ratio is controlled at: 10:1. At the ball mill speed of 400 rpm, ball milling for 15 minutes, so that the surface of the ball milling beads and the inner surface of the ball milling equipment are adhered to one another. layer carbon material, and separate the remaining carbon material powder and ball milling beads by sieving, and then pour the ball milling beads back into the ball milling tank for use in the next process.

[0054] Step 2, add a certain mass of ternary cathode material (LiNi 0.84 co 0.1 mn 0.06 o 2 ) into the ball milling equipment for ball milling the carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com