Test table used for studying friction vibration energy recycling efficiency

A technology of energy recovery efficiency and friction vibration, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as the difficulty of rational utilization of friction and vibration, and achieve easy miniaturization, no electromagnetic interference, and energy conversion. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

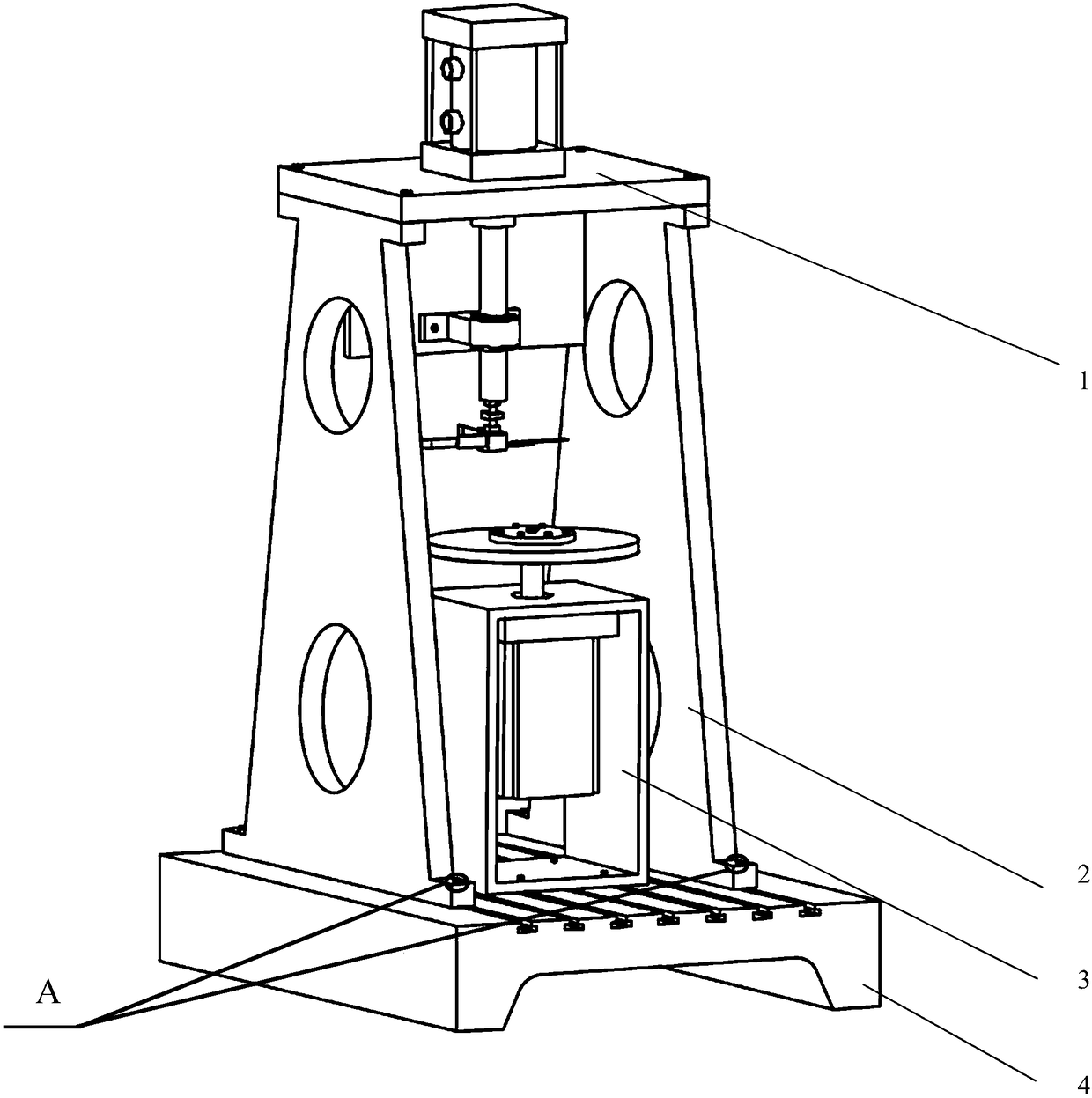

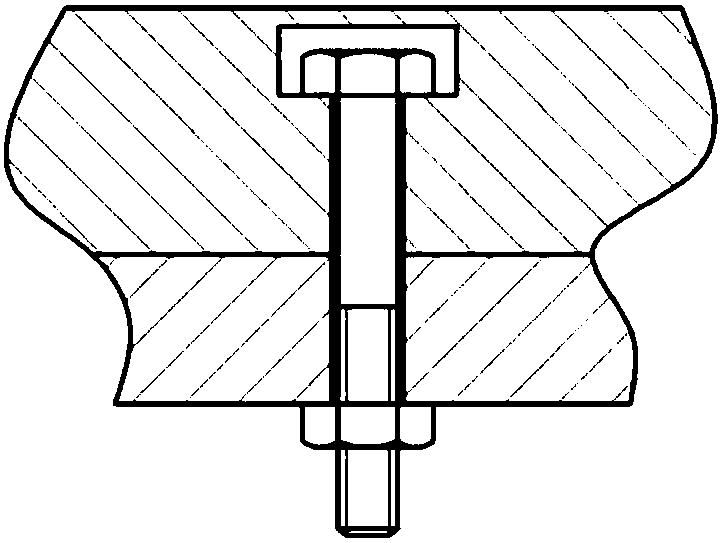

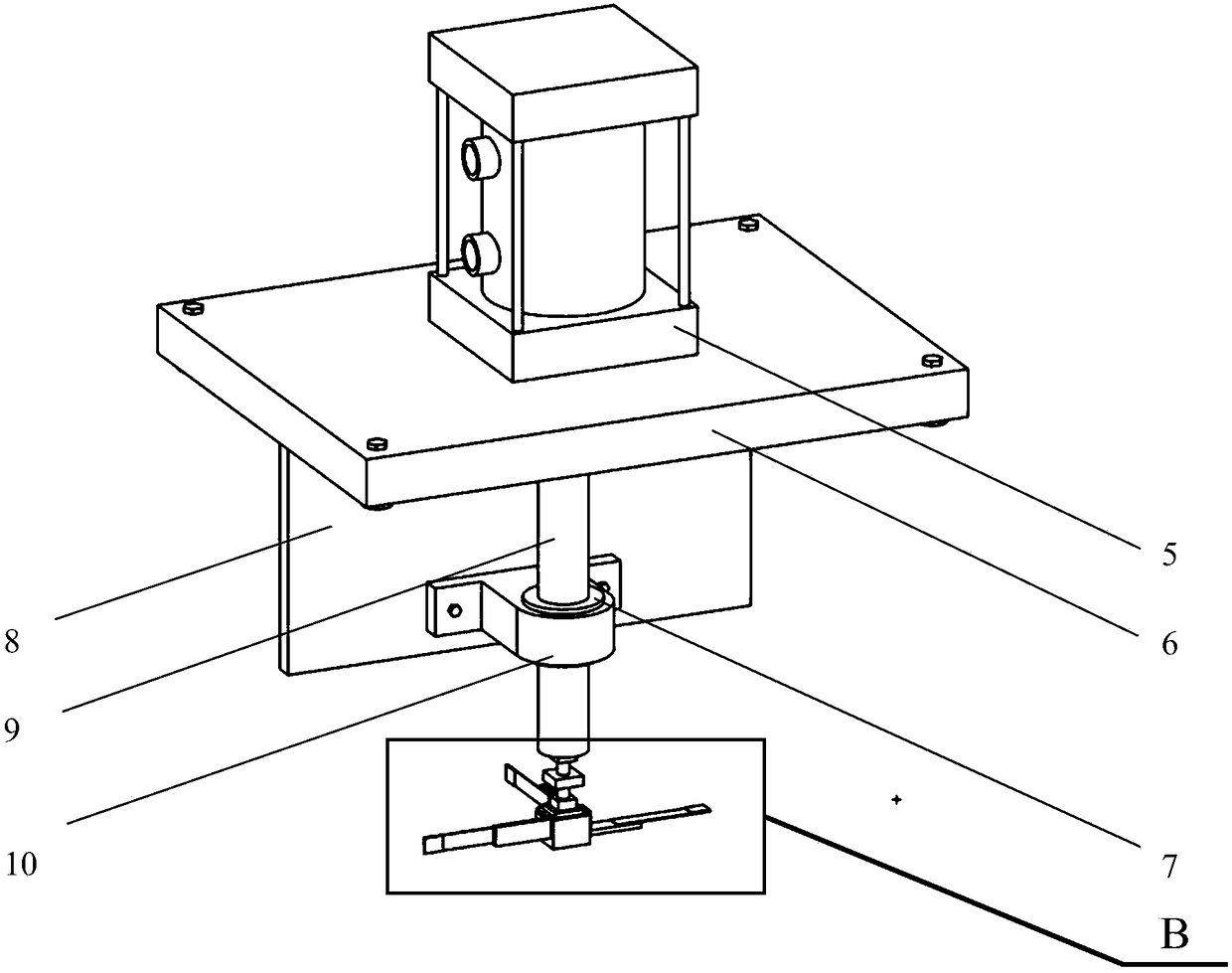

[0038] figure 1 Shown is a test bench for studying the energy recovery efficiency of friction vibration, which is composed of a machine base 4, a motor module 3, and a loading module 1; the machine base 4 is provided with multiple parallel inverted T-shaped notches; the motor module 3 has a structure of : the hollow support 21 is surrounded by the left and right side vertical plates, the upper top plate and the lower base plate, the servo motor 20 is installed on the bottom of the lower base plate of the hollow support 21, and the output shaft of the servo motor is connected from the top of the hollow support 21 Stretch out in the hole on the top plate, the brake disc 19 is fixed on the flange 18 through bolts, and the flange is fixed on the output shaft of the servo motor, (see Figure 3A, the lower flange is welded on the upper end of the output shaft of the servo motor, and the brake disc is fixed on the lower flange by bolts through the upper flange) on the inverted T-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com