Ageing treatment process for Al-Er-Li alloy

An al-er-li and aging treatment technology, which is applied in the field of Al-Er-Li alloy aging treatment technology, can solve the problems of slow diffusion of Sc and inability to further improve the strength of Al-Li alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The mass percentage of each component of the alloy is Er 0.19%, Li 2.1%, the content of unavoidable magazine is less than 0.1%, and the balance is Al. After smelting to obtain an ingot, it is subjected to solution treatment (first-level solution treatment at 580°C / 24h, and then solution treatment at 640°C / 24h).

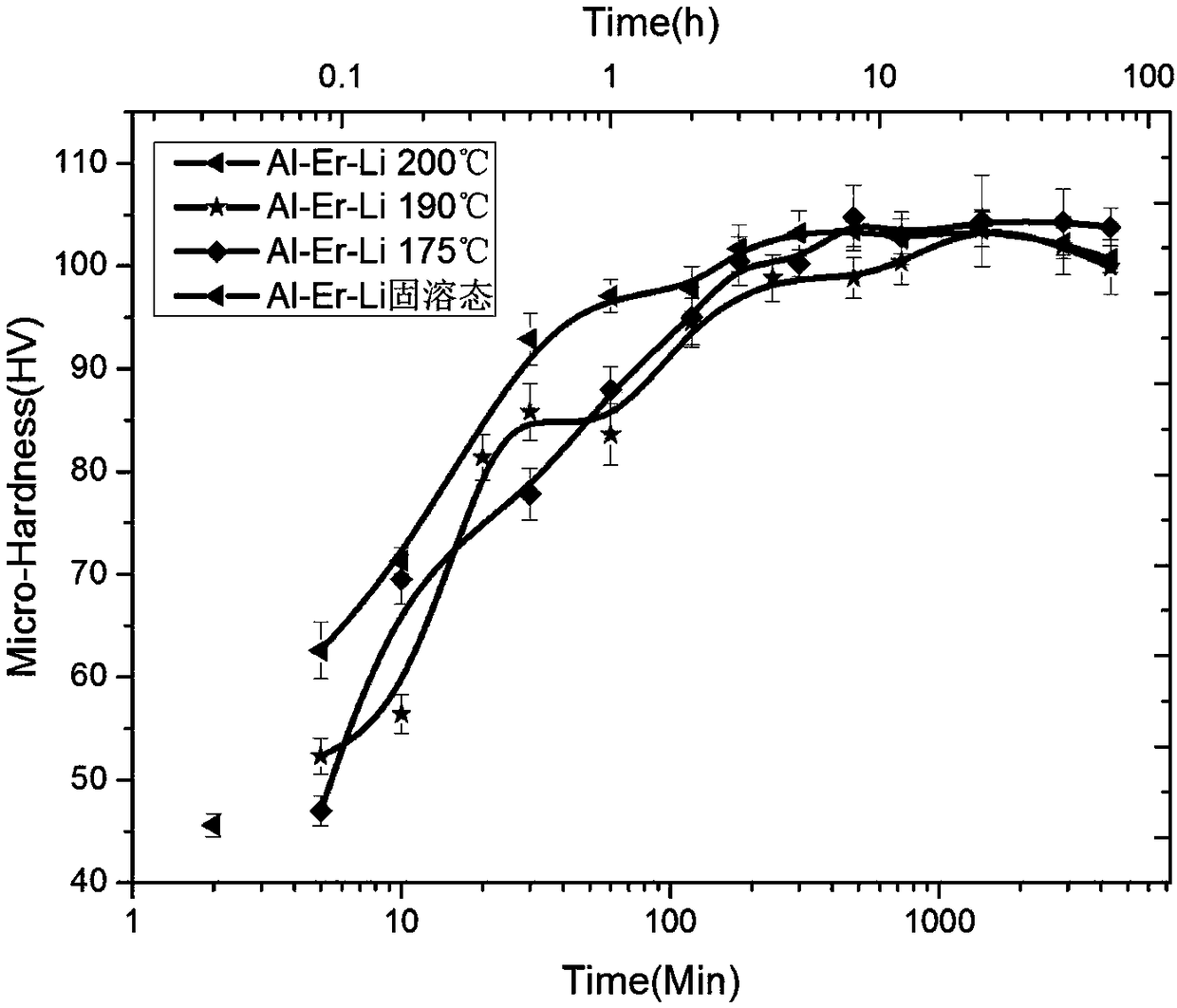

[0016] The solution-treated samples were subjected to isothermal aging treatment at 175, 190, and 200 °C, and their mechanical properties were characterized by microhardness. The hardness curves of Al-Er-Li alloy at 175, 190, and 200 °C were obtained. like figure 1 shown.

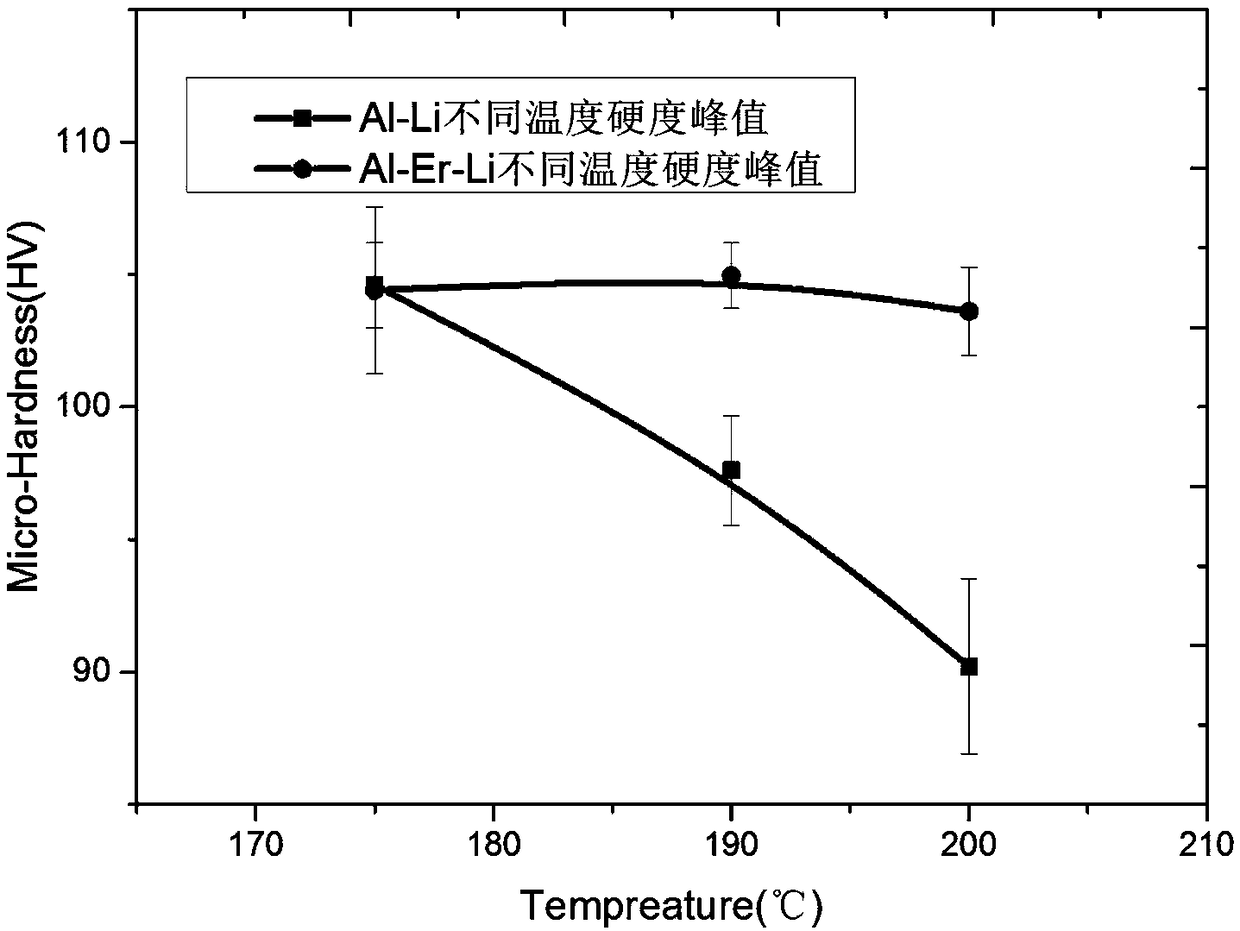

[0017] Depend on figure 1 It can be seen that the peak aging hardness of Al-Er-Li alloy after isothermal aging treatment at 175 ℃, 190 ℃ and 200 ℃ remains at 104HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com