High-temperature powder-containing gas cooling treatment and heat recovery device

A heat recovery device, gas technology, applied in the direction of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of fine powder agglomeration, achieve the effect of improving heat exchange efficiency, avoiding blockage, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

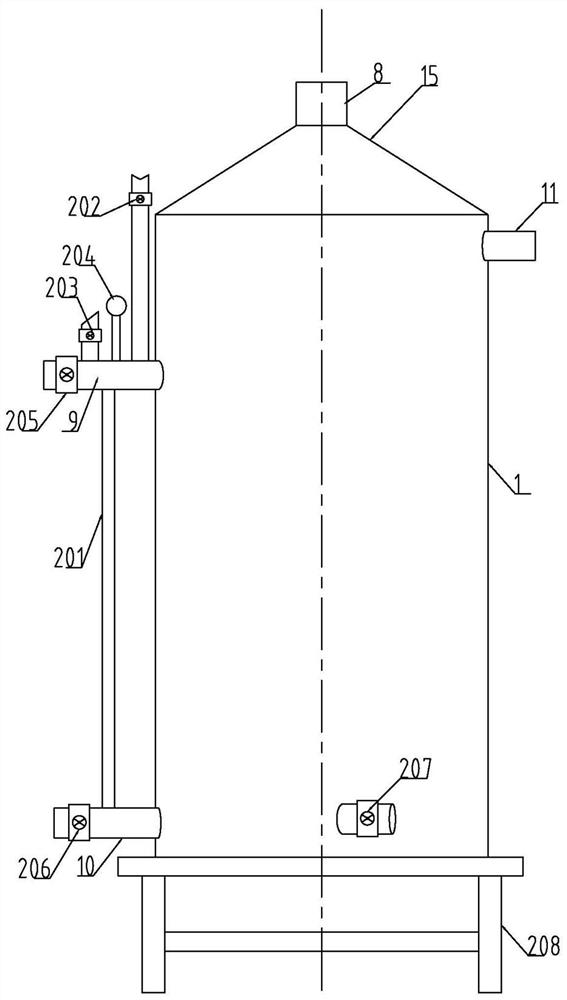

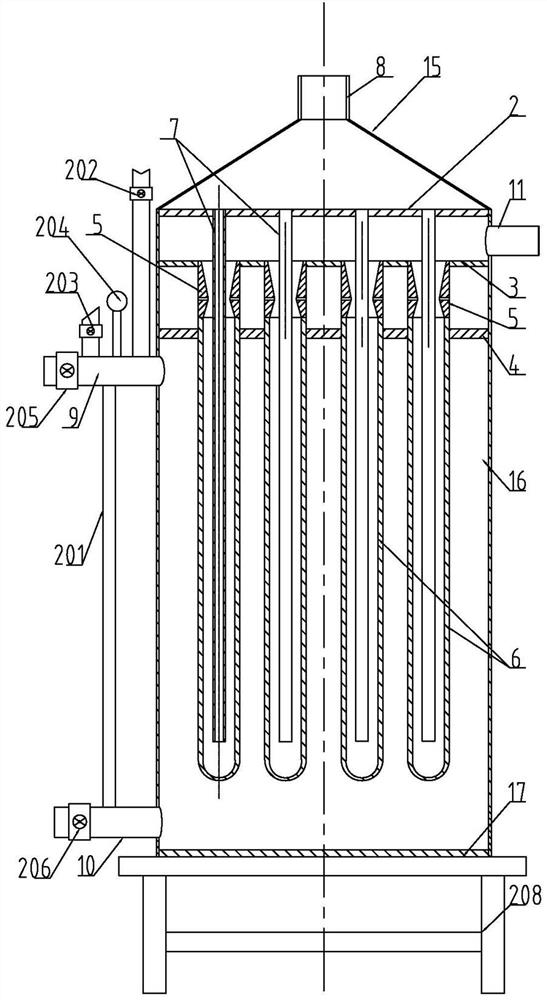

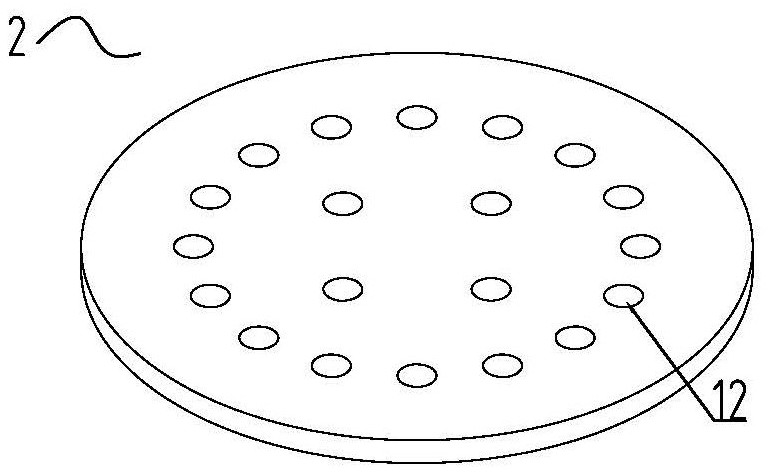

[0021] Embodiment 1: The present invention produces the ethanol cracking furnace gas of nano-scale carbon powder material (temperature is up to more than 800 ℃, contains water vapor and carbonaceous fine powder with higher concentration before operation and prepares each part described above and connects each part Assembled, the inner diameter of the hot gas inlet pipe 11 is 250 mm, the total height of the cylindrical shell part 1 is 3.8 meters, the total height of the cylindrical shell 16 is 3.0 meters, the inner diameter of the cylindrical shell 16 is 2.5 meters, and the length of the heat exchange branch pipe 6 is 2.5 meters, the inner diameter of the heat exchange branch pipe 6 is 25mm. During use, the hot gas inlet pipe 11 is connected with the ethanol cracking furnace gas through the external hot gas valve, and the cooling gas outlet pipe 8 is connected with the external powder valve through the external gas valve. The body collector (electric trap) is connected well, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com