A kind of multifunctional cleaning drag reducing agent for shale gas fracturing and preparation method thereof

A drag reducer and multi-functional technology, applied in the field of multi-functional clean drag reducer for shale gas fracturing and its preparation, can solve the problems of high cost, complicated on-site liquid preparation operation, large workload, etc. resistance, reducing the on-site construction workload, and avoiding the effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

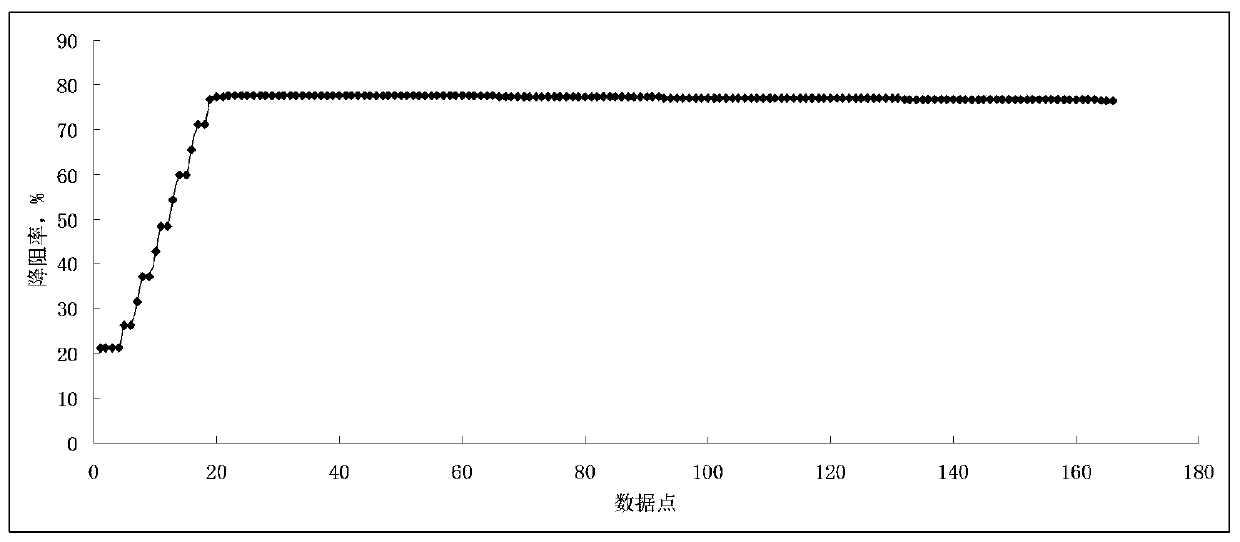

Image

Examples

Embodiment 1

[0029] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0030] S1, external phase preparation: 80g glycerol carbonate and 100g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 4 H) Mix and stir evenly, set aside.

[0031] S2. Internal phase preparation: add 100g (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 50g N-vinylpyrrolidone, and 150g potassium formate into 519.98g of water, stir and dissolve evenly, and set aside .

[0032] S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas and stir at high speed to remove oxygen. After stirring for 20min-40min, add 0.01g of ammonium persulfate and 0.01g of ...

Embodiment 2

[0034] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0035] S1, external phase preparation: 120g glycerol carbonate and 60g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 20 H) Mix and stir evenly, set aside.

[0036] S2. Internal phase preparation: add 140g of (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 79.9g of N-vinylpyrrolidone, and 200g of sodium acetate into 400g of water, stir and dissolve evenly, and set aside.

[0037] S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas at high speed and stir to remove oxygen. After stirring for 20min-40min, add 0.1g ammonium persulfate initiator int...

Embodiment 3

[0039] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0040] S1, external phase preparation: 100g glycerol carbonate and 80g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 12 H) Mix and stir evenly, set aside.

[0041] S2. Internal phase preparation: add 120g (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 59.95g N-vinylpyrrolidone, and 180g sodium citrate into 460g of water, stir and dissolve evenly, and set aside .

[0042]S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas at high speed and stir to remove oxygen. After stirring for 20min-40min, add 0.05g of sodium bisulfite initiator into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com