A kind of preparation method of polyvinyl chloride resin special for chlorination

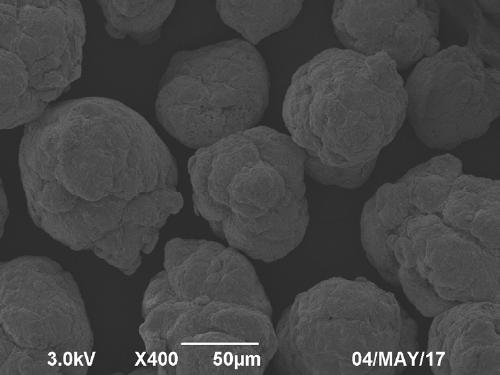

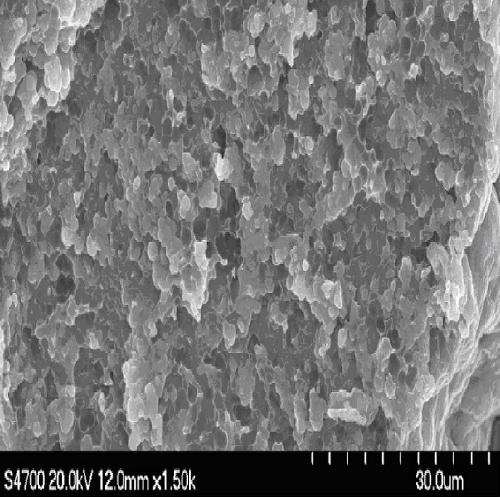

A technology of polyvinyl chloride resin and vinyl chloride monomer, which is applied in the field of organic synthesis, can solve the problems of film thickness and low film coverage, achieve less film, improve particle distribution concentration and apparent density, and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The DCS control system automatically controls the addition of 62.5 kg of quality agent and 25 tons of vinyl chloride monomer into the closed polymerization kettle. After pre-mixing for 40 minutes, 29 tons of deionized water, 4.3 kg of main dispersant I, 8.2 kg main dispersant II, 8kg dibutyltin dilaurate, 5kg ammonium bicarbonate, 8.5kg tert-butyl peroxyneodecanoate, 8.5kg bis(3,5,5)-trimethylhexanoyl peroxide, 0.85kg mercapto Ethanol and other materials are automatically and accurately added to 70m through the closed feeding technology under the control of the DCS system 3 In the polymerization kettle, after cold stirring for 20 minutes, the temperature is automatically raised to the reaction temperature of 61.5°C for polymerization. After 90 minutes of reaction, 2.5kg of mercaptoethanol is added again, and the polymerization reaction is carried out for 4.5 hours. The pressure is reduced by 0.05MPa and 15kg of terminator is automatically added to terminate. The polyvin...

Embodiment 2

[0047] The DCS control system automatically controls adding 50kg of quality agent and 25 tons of vinyl chloride monomer into the closed polymerization kettle. After premixing for 30 minutes, 29 tons of deionized water, 4.3kg of main dispersant I, and 8.2kg of Main dispersant II, 8kg containing thioctyl tin, 5kg ammonium bicarbonate, 8.5kg tert-butyl peroxyneodecanoate, 8.5kg bis(3,5,5)-trimethylhexanoyl peroxide, 0.85kg mercaptoethanol and other materials , through closed feeding technology, under the control of DCS system, automatically and accurately add 70m 3 In the polymerization kettle, after cold stirring for 30 minutes, the temperature is automatically raised to the reaction temperature of 61.5°C for polymerization. After 90 minutes of reaction, 2.5kg of mercaptoethanol is added again, and the polymerization reaction is 4.0h. The pressure is reduced by 0.01MPa and 15kg of terminator is automatically added to terminate. The polyvinyl chloride resin slurry specially used ...

Embodiment 3

[0049] The DCS control system automatically controls the addition of 31.25 kg of quality agent and 25 tons of vinyl chloride monomer into the closed polymerization kettle. After pre-mixing for 20 minutes, 29 tons of deionized water, 4.3 kg of main dispersant I, 8.2 kg main dispersant II, 8kg fatty acid zinc, 5kg ammonium bicarbonate, 8.5kg tert-butyl neodecanoate, 8.5kg bis(3,5,5)-trimethylhexanoyl peroxide, 0.85kg mercaptoethanol and other materials , through closed feeding technology, under the control of DCS system, automatically and accurately add 70m 3 In the polymerization kettle, after cold stirring for 40 minutes, the temperature is automatically raised to the reaction temperature of 61.5°C for polymerization. After 90 minutes of reaction, 5.5kg of trichlorethylene is added again, and the polymerization reaction is 4.0h. The pressure is reduced by 0.01MPa and 15kg of terminator is automatically added. The polymerization reaction is terminated to obtain polyvinyl chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com