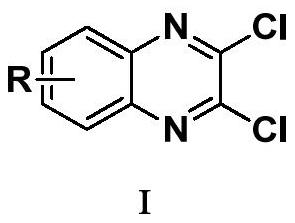

Method for preparing 2,3-dichloroquinoxaline derivatives in one pot

A technology of dichloroquinoxaline and derivatives, which is applied in the field of drug synthesis, can solve the problems of corrosion of reaction vessel, inconvenient post-processing, complicated operation and the like, and achieves the effects of mild reaction conditions, simple operation and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

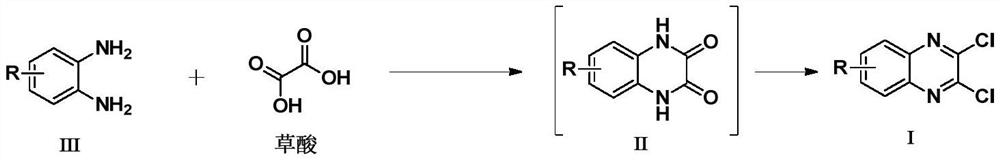

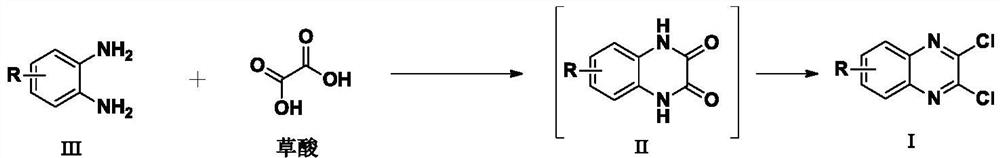

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 2,3-dichloroquinoxaline

[0021] Weigh 1g of o-phenylenediamine, 1.28g of oxalic acid and 3g of 200-300 mesh silica gel in a reaction bottle, add 15ml of toluene, and react at 110°C for 5 hours. After the reaction is complete, add 8.4ml of phosphorus oxychloride and 5ml of DMF, Continue to react for 1 hour, when the reaction is complete, add 50ml of ice water to quench, add 50ml of ethyl acetate, filter, separate the liquids, continue to extract the water layer with ethyl acetate, combine the ethyl acetate layers, wash with saturated sodium chloride, anhydrous sulfuric acid Dry over sodium, filter, and dry under reduced pressure to obtain a white solid with a yield of 92% and a melting point of 148-150°C.

[0022] IR(KBr,ν,cm -1 ):3104,3042,1557,1530,1484,1457,1271,1179,1125,1018, 991,768,599,436; 1 H NMR (600MHz, CDCl 3 )(δ,ppm):7.76-7.84(m,2H), 7.99-8.06(m,2H).;ESI–MS:[M+H] + m / z 198.9.

Embodiment 2

[0023] Embodiment 2 The preparation of 2,3-dichloroquinoxaline

[0024] Weigh 1g of o-phenylenediamine, 1.17g of oxalic acid and 4g of 200-300 mesh silica gel in a reaction flask, add 15ml of toluene, and react at 100°C for 5 hours. After the reaction is complete, add 6.7ml of phosphorus oxychloride and 5ml of DMF, Continue to react for 1 hour, when the reaction is complete, add 50ml of ice water to quench, add 50ml of ethyl acetate, filter, separate the liquids, continue to extract the water layer with ethyl acetate, combine the ethyl acetate layers, wash with saturated sodium chloride, anhydrous sulfuric acid Dry over sodium, filter, and dry under reduced pressure to obtain a white solid with a yield of 90% and a melting point of 148-150°C.

Embodiment 3

[0025] The preparation of embodiment 3 2,3-dichloroquinoxaline

[0026] Weigh 1g of o-phenylenediamine, 1.40g of oxalic acid and 5g of 100-200 mesh silica gel in a reaction bottle, add 15ml of toluene, and react at 110°C for 5 hours. After the reaction is complete, add 4.5ml of phosphorus oxychloride and 5ml of DMF, Continue to react for 1 hour, when the reaction is complete, add 50ml of ice water to quench, add 50ml of ethyl acetate, filter, separate the liquids, continue to extract the water layer with ethyl acetate, combine the ethyl acetate layers, wash with saturated sodium chloride, anhydrous sulfuric acid Dry over sodium, filter, and dry under reduced pressure to obtain a white solid with a yield of 88% and a melting point of 148-150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com