Stone grinding and polishing machine

A mechanical and stone technology, applied in the field of stone grinding and polishing machinery, can solve the problems of unsustainable water supply, inability to remove small stone particles, and affect the effect of grinding, so as to achieve the effect of increasing service life, increasing quality, and improving grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, such as Figure 4 When the surface of the stone needs to be cleaned, the negative pressure fan 23 can be turned on to generate a negative pressure airflow, and the fine particles can be sucked into the dust suction pipe 20 through the dust suction cover 30, and discharged into the dust suction bin 22 through the dust discharge cover 21. Inside, the stones are stuck on the surface of the dust removal net 31, and when the inside of the dust collection bin 22 needs to be cleaned, the cleaning cover 40 can be opened to clean the inside.

Embodiment 2

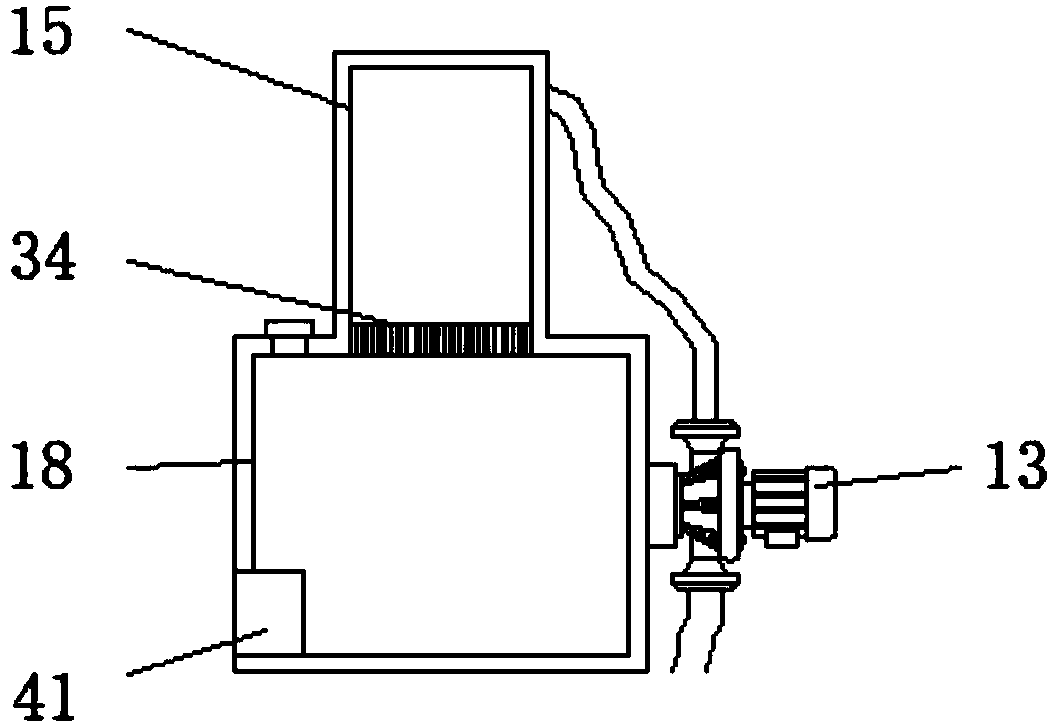

[0025] Example 2, such as Figure 5When water needs to be sprayed during the grinding process, the second water pump 41 can be turned on to spray the water inside the water tank 18 from the water outlet 42 onto the surface of the stone, and the shielding groove 4 can limit the sprayed water to avoid splashing , can save water, can open water pump 13 simultaneously and excess water is sucked into the inside of filter box 15, is discharged into the inside of water tank 18 by the filtration of filter screen 34 again and reclaims water resource, continues to wash stone material.

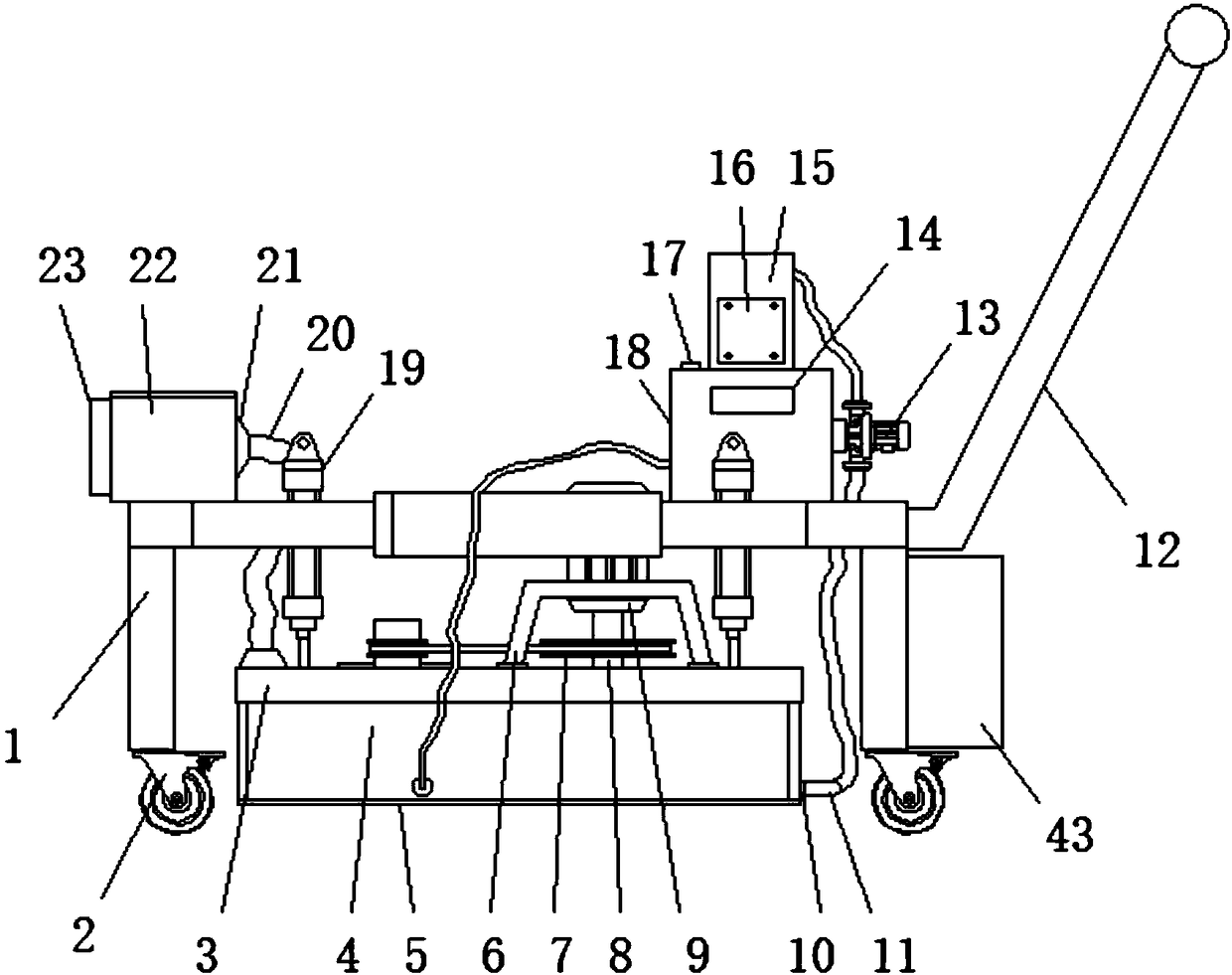

[0026] Working principle: charge the storage battery 43 before use. When in use, the storage battery 43 supplies power to the device. First, push the device to the top of the stone, adjust the position of the grinding structure through the pneumatic cylinder 19, turn on the motor 9, and drive the first rotating column 8 to rotate. Thereby drive main grinding sheet 29 to rotate, and first belt pulley 7 tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com