A dust removal equipment for the production of coated sand

A technology of dust removal equipment and coated sand, which is applied in the field of dust removal equipment for the production of coated sand, can solve the problems of pollution in the production of coated sand, achieve the effects of increased dust removal effect, simple structure, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

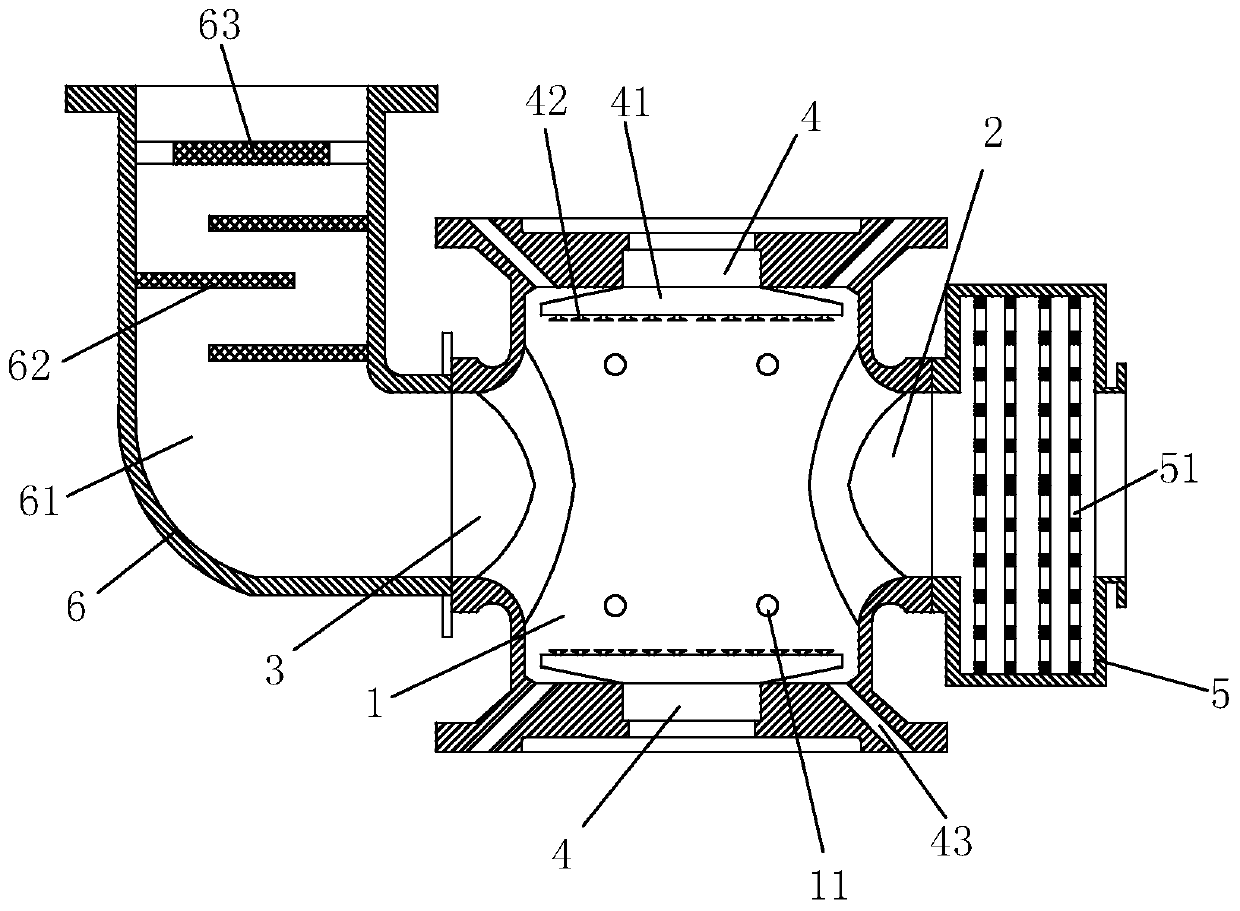

[0009] Such as figure 1 As shown, the dust removal equipment for the production of coated sand according to the present invention includes a cylindrical cylinder 1, which is an inner hollow cavity, and its volume can be adjusted according to actual production needs. Both ends of the cylindrical barrel 1 are respectively provided with an air inlet 2 and an air outlet 3 , and the upper and lower ends of the cylindrical barrel 1 are provided with water spray outlets 4 .

[0010] Such as figure 1 As shown, an air inlet filter 5 is connected at the air inlet 2, and the filter screen 51 is provided with layers of layers on the air inlet filter 5. A layer of small dust particles with a larger diameter is filtered out.

[0011] Such as figure 1 As shown, a water spray seat 41 is provided at the water spray port 4, and some small shower heads 42 are arranged on the water spray seat 41. The curtain, the spray water curtain is in contact with the air in the cylindrical barrel 1, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com