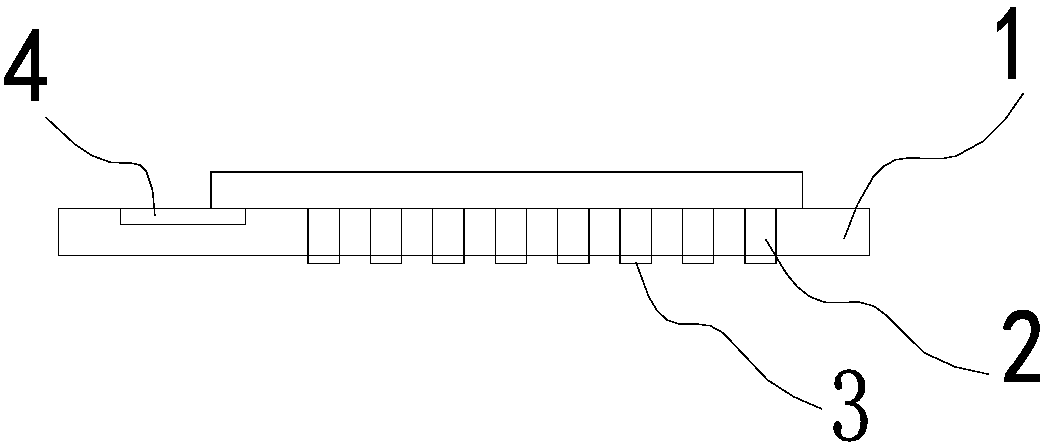

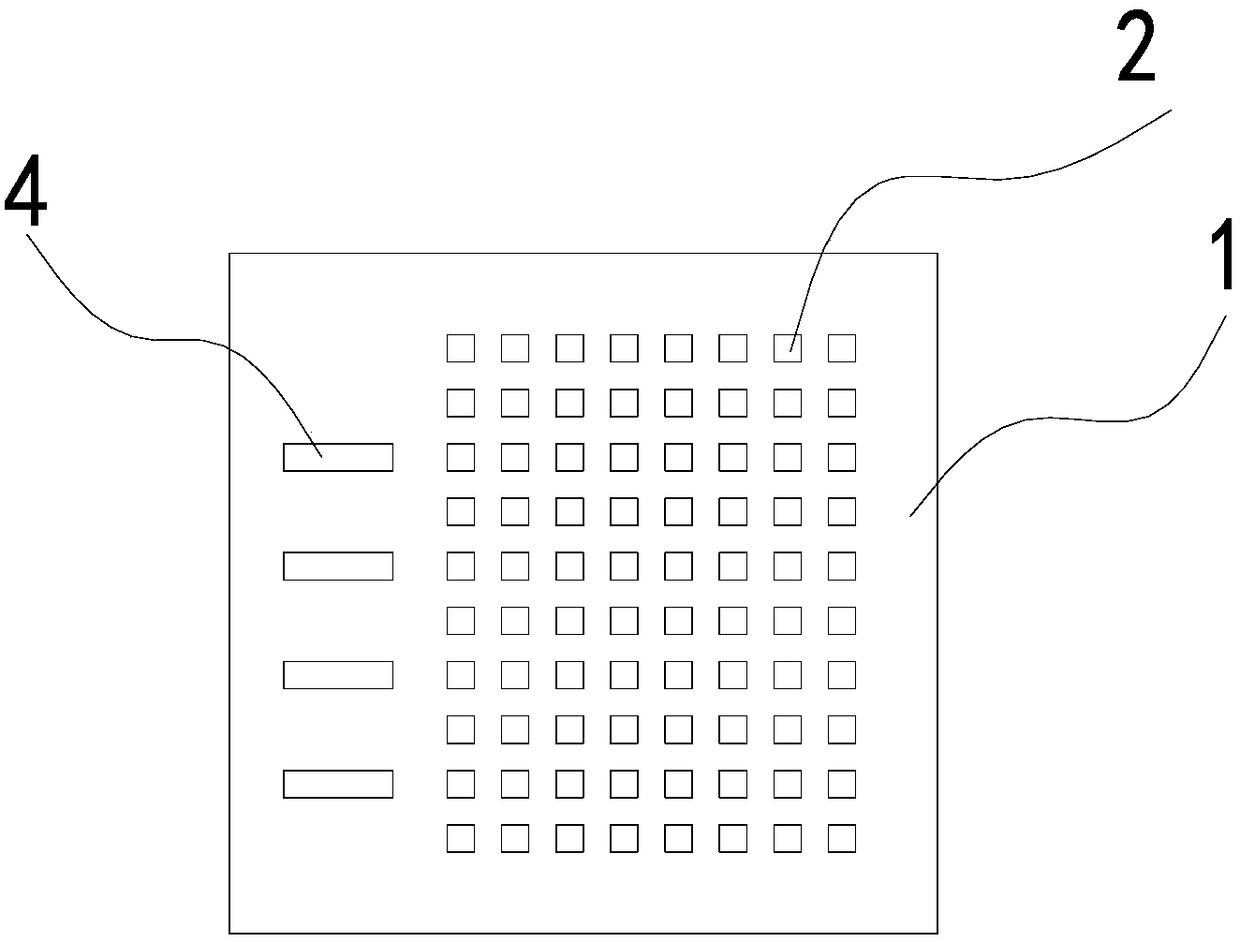

Nerve stimulator and manufacturing method thereof

A manufacturing method and nerve stimulation technology, which is applied in the field of medical equipment, can solve the problems of small stimulation electrode density and poor stimulation effect, achieve good therapeutic effect, overcome high-density nerve stimulation electrodes, and novel technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Step 1: Select a glass substrate and heat it until its material softens;

[0058] Step 2: Squeeze and embed the metal pillars of the metal substrate with several metal pillars cut into the softened glass substrate, so that the metal pillars are completely wrapped by the glass substrate;

[0059] Step 3: cooling and forming.

Embodiment 2

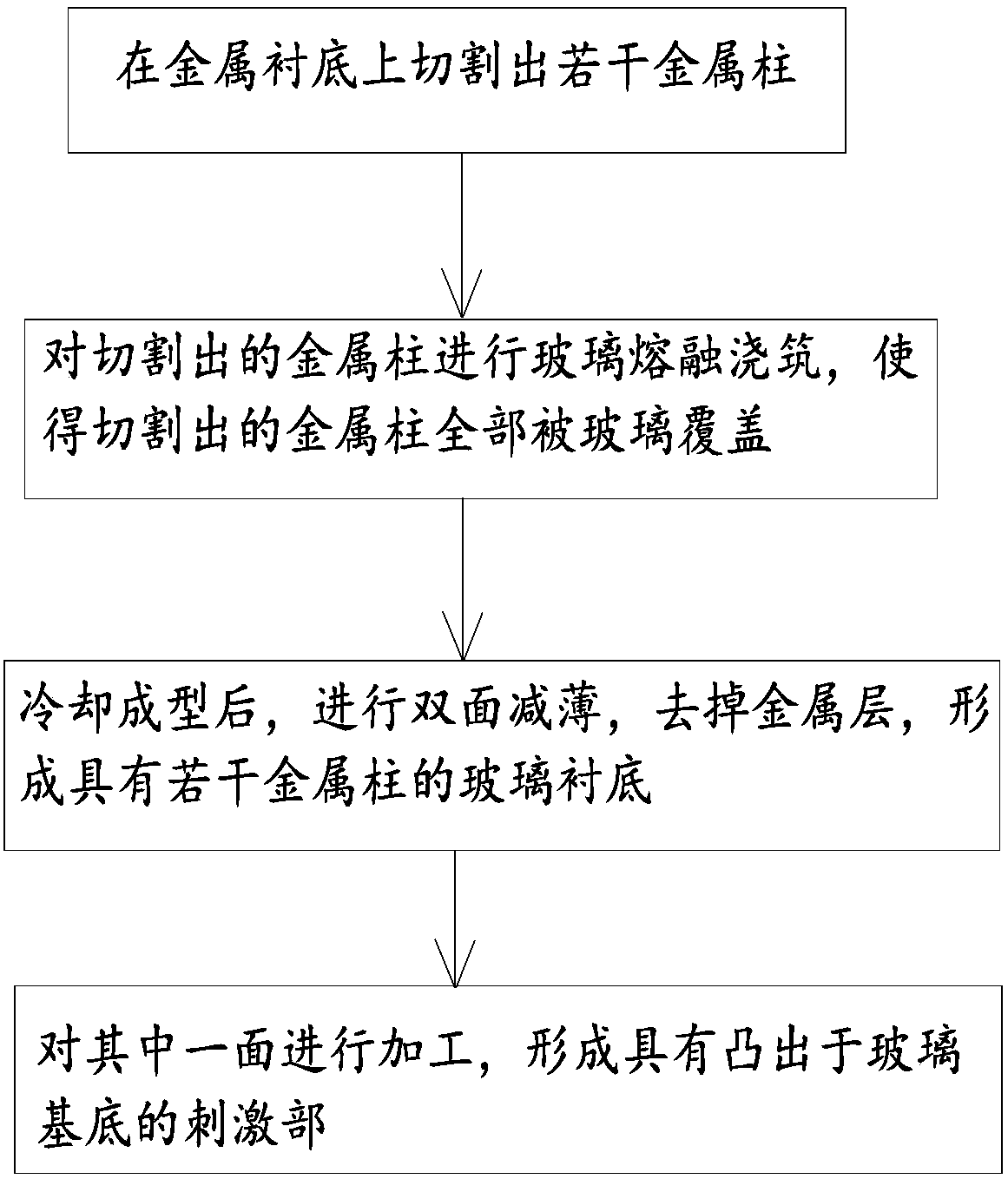

[0061] Step 1: Heating the glass to a molten state in a molten state;

[0062] Step 2: Pouring molten glass on one side of the metal column on the metal substrate, so that the liquid glass covers all the metal column;

[0063] Step 3: cooling and forming.

Embodiment 3

[0065] Step 1: Cut out the metal pillar on the metal substrate and fill it with glass frit;

[0066] Step 2: Heating the metal substrate and the glass powder on it so that the glass powder melts and precipitates on the metal substrate to form a layer of molten glass.

[0067] Step 3: cooling and forming.

[0068] After the above steps, it is generally necessary to further heat and squeeze the glass to reduce the gap between it and the metal column.

[0069] Since the neurostimulator needs to be implanted in the body, the biocompatibility requirements of the materials used are relatively high, so the metal substrate of the metal column and pad structure is generally made of titanium or platinum or iridium or tantalum or gold or other materials. Alloys and other biocompatible metal materials.

[0070] The thickness of the metal substrate is generally between 0.3mm-1.5mm, which can ensure the length of the metal column cut out, and at the same time, the processing efficiency wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com