A kind of whitening moisturizing cream and preparation method thereof

A technology of whitening, moisturizing and rotating speed is applied in the field of whitening, moisturizing and repairing cream and its production, which can solve the problems of human organ lesions and skin pigmentation, and achieve the effects of simple process, good product cost and control of product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

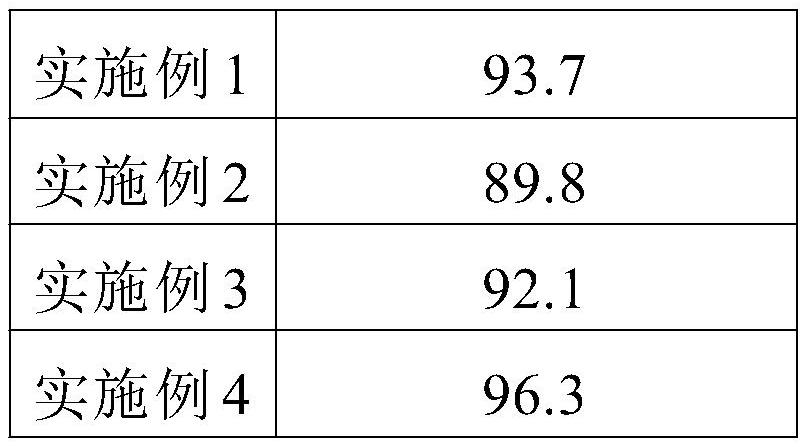

Examples

Embodiment 1

[0044] Whitening, moisturizing and repairing cream, prepared from the following raw materials in parts by weight: 3.5 parts of glycerin, 1.5 parts of 1,3-butanediol, 2 parts of biosurfactant, 2.5 parts of natto extract, 45 parts of deionized water Coenzyme Q102, Licochalcone A 0.1, Vitamin 0.8, Lanolin 1.5, Ester Oil 2.5, Ceramide 0.9, Natural Vegetable Oil 1.5.

[0045] Described natural vegetable oil is camellia oil.

[0046] The preparation method of the natto extract is as follows: crush the natto through a 20-mesh sieve, then add it to an aqueous glycerin solution 20 times the weight of the natto, perform ultrasonic extraction for 40 minutes, and centrifuge at 6000 r / min for 20 minutes to obtain the supernatant Filter with a 300-mesh filter cloth, and concentrate the filtrate to 1 / 2 of the volume of the original filtrate at a temperature of 60° C. and a vacuum of 0.02 MPa to obtain a natto extract.

[0047] The mass fraction of glycerin in the glycerin aqueous solution i...

Embodiment 2

[0058] Whitening, moisturizing and repairing cream, prepared from the following raw materials in parts by weight: 3.5 parts of glycerin, 1.5 parts of 1,3-butanediol, 2 parts of biosurfactant, 2.5 parts of natto extract, 45 parts of deionized water Coenzyme Q102, Licochalcone A 0.1, Vitamin 0.8, Lanolin 1.5, Ester Oil 2.5, Ceramide 0.9, Natural Vegetable Oil 1.5.

[0059] Described natural vegetable oil is camellia oil.

[0060] The preparation method of the natto extract is as follows: crush the natto through a 20-mesh sieve, then add it to an aqueous glycerin solution 20 times the weight of the natto, perform ultrasonic extraction for 40 minutes, and centrifuge at 6000 r / min for 20 minutes to obtain the supernatant Filter with a 300-mesh filter cloth, and concentrate the filtrate to 1 / 2 of the volume of the original filtrate at a temperature of 60° C. and a vacuum of 0.02 MPa to obtain a natto extract.

[0061] The mass fraction of glycerin in the glycerin aqueous solution i...

Embodiment 3

[0072] Whitening, moisturizing and repairing cream, prepared from the following raw materials in parts by weight: 3.5 parts of glycerin, 1.5 parts of 1,3-butanediol, 2 parts of biosurfactant, 2.5 parts of natto extract, 45 parts of deionized water Coenzyme Q102, Licochalcone A 0.1, Vitamin 0.8, Lanolin 1.5, Ester Oil 2.5, Ceramide 0.9, Natural Vegetable Oil 1.5.

[0073] Described natural vegetable oil is camellia oil.

[0074] The preparation method of the natto extract is as follows: crush the natto through a 20-mesh sieve, then add it to an aqueous glycerin solution 20 times the weight of the natto, perform ultrasonic extraction for 40 minutes, and centrifuge at 6000 r / min for 20 minutes to obtain the supernatant Filter with a 300-mesh filter cloth, and concentrate the filtrate to 1 / 2 of the volume of the original filtrate at a temperature of 60° C. and a vacuum of 0.02 MPa to obtain a natto extract.

[0075] The mass fraction of glycerin in the glycerin aqueous solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com