Composite silicon powder embedding aluminum-rich nano particles as well as preparation method and application thereof

A nanoparticle and silicon powder technology, applied in the field of silicon powder, can solve problems such as affecting the cycle life of lithium batteries, and achieve the effects of promoting charge and mass transfer, relieving stress, and high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

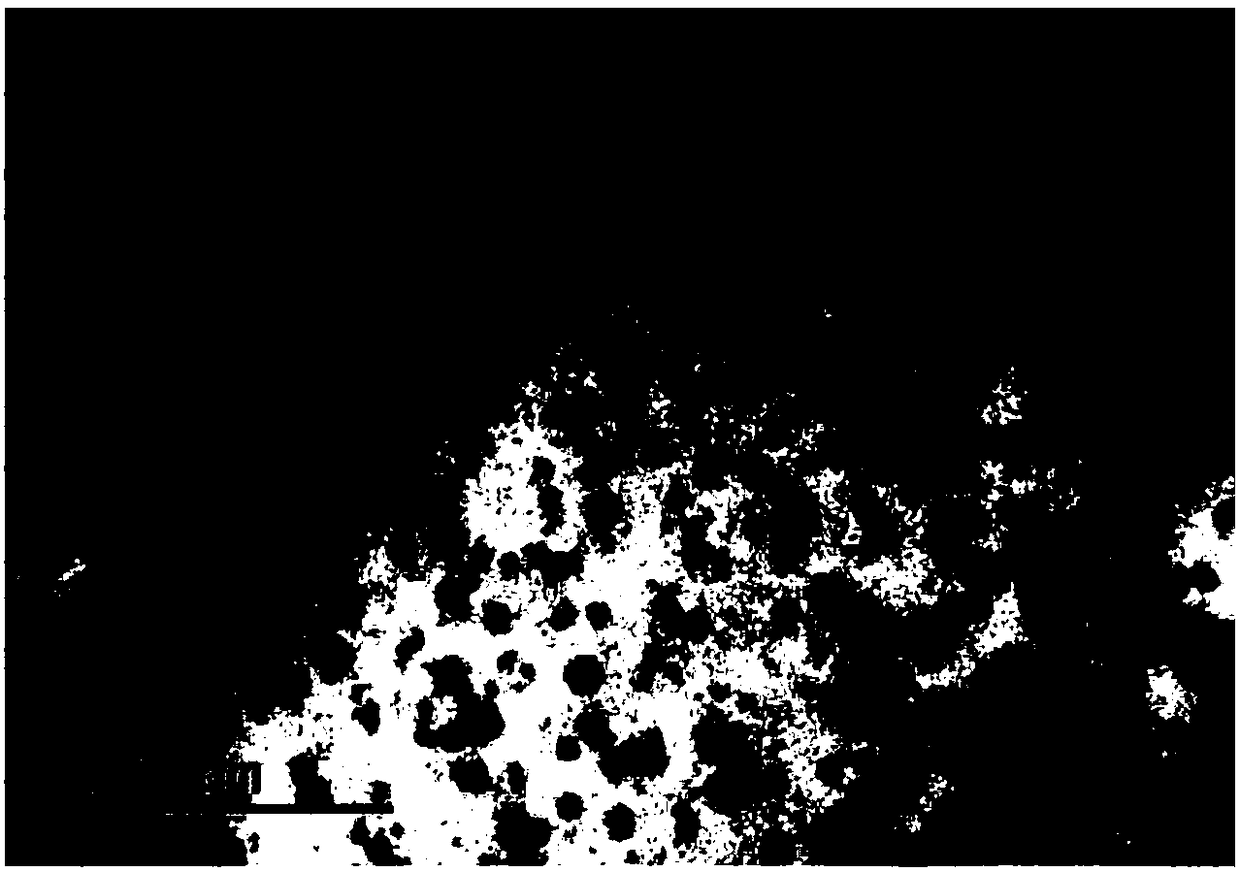

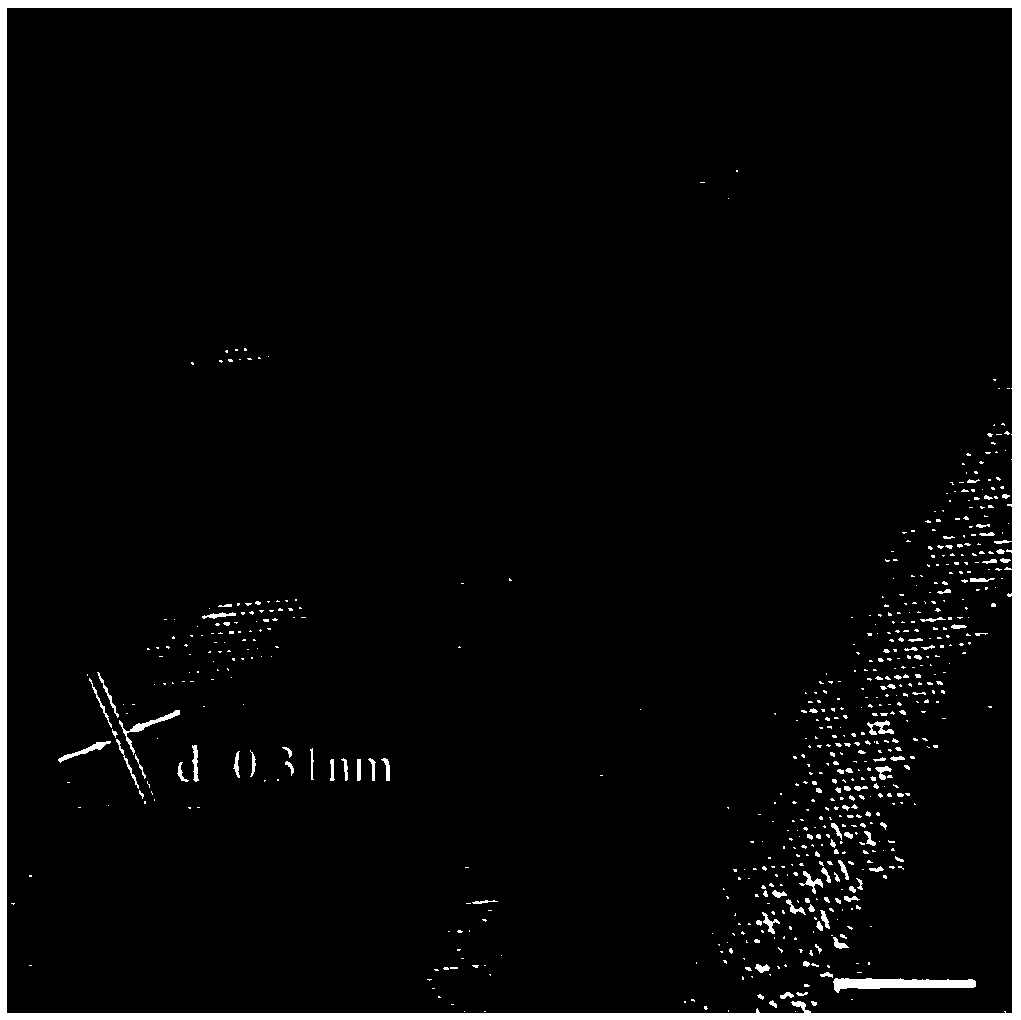

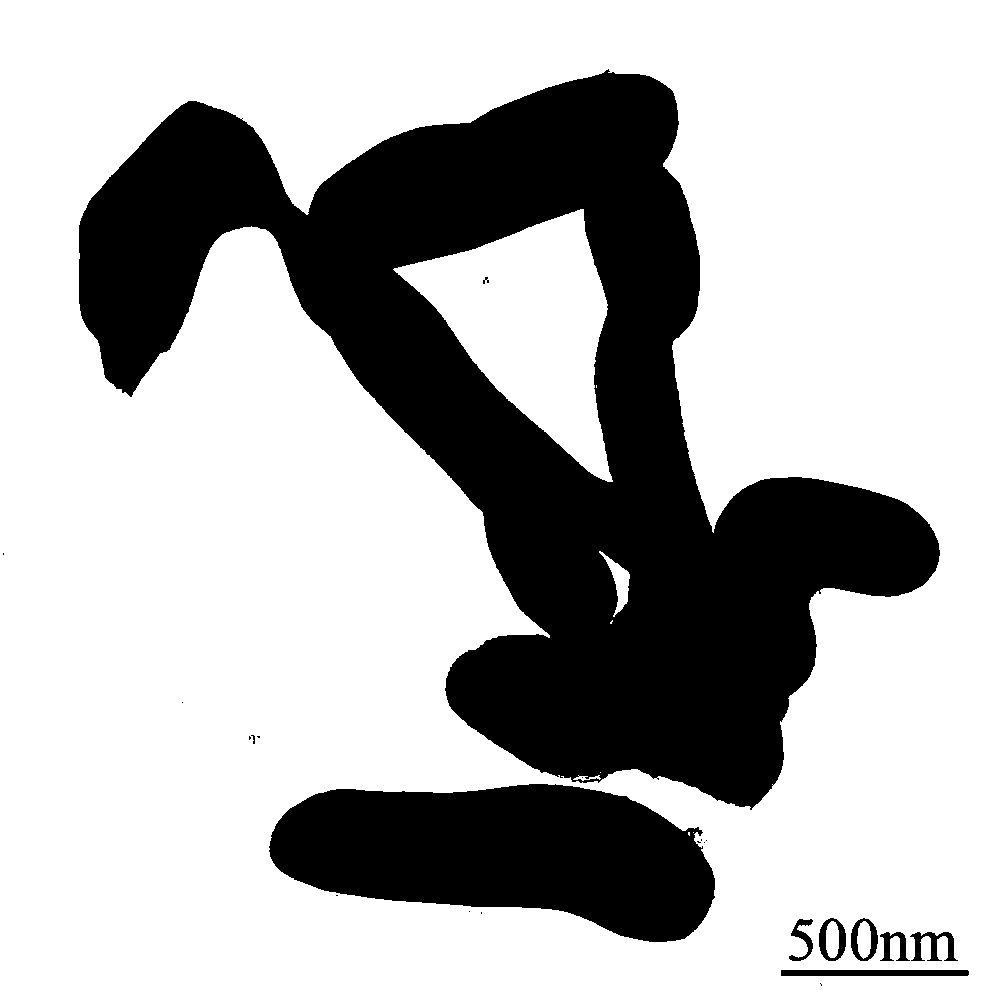

Image

Examples

preparation example Construction

[0036] A method for preparing composite silicon powder embedded with aluminum-rich nanoparticles of the present invention comprises the following steps:

[0037] 1) get industrial aluminum, industrial silicon and modifier, and set aside;

[0038] 2) Heat the industrial aluminum until it melts, add industrial silicon and a modifier, mix evenly, and keep it warm for 15-90 minutes at 570-850°C to obtain an aluminum-silicon alloy melt;

[0039] 3) cooling and molding the aluminum-silicon alloy melt obtained in step 2) at a cooling rate of 0.1-100° C. / s to obtain an aluminum-silicon alloy;

[0040] 4) cutting the aluminum-silicon alloy obtained in step 3) into small pieces, placing it in an inorganic acid with a mass concentration of 5-10%, and chemically etching it for 100-120 hours to obtain the etched aluminum-silicon alloy;

[0041] 5) taking the corroded aluminum-silicon alloy obtained in step 4), soaking, stirring, and standing for 4-150h;

[0042] 6) Take the supernatant m...

Embodiment 1

[0048] A method for preparing composite silicon powder embedded with aluminum-rich nanoparticles of the present invention comprises the following steps:

[0049] 1) Weigh the raw materials according to the following weight percentages: 99.0% of industrial aluminum, 0.9% of industrial silicon, and 0.6% of modificator, for future use, wherein the modificator is Sb;

[0050] 2) Put industrial aluminum in an induction furnace, heat it to melt, add industrial silicon and modifier, mix evenly, and keep it warm for 15 minutes at 850°C to obtain an aluminum-silicon alloy melt;

[0051] 3) cooling and molding the aluminum-silicon alloy melt obtained in step 2) in a clay crucible with a diameter of 50 mm at a cooling rate of 0.1° C. / s to obtain an aluminum-silicon alloy;

[0052] 4) cutting the aluminum-silicon alloy obtained in step 3) into small pieces, placing it in dilute sulfuric acid with a mass concentration of 5%, and chemically etching it for 100 hours to obtain the etched alum...

Embodiment 2

[0057] A method for preparing composite silicon powder embedded with aluminum-rich nanoparticles of the present invention comprises the following steps:

[0058] 1) Weigh the raw materials according to the following weight percentages: 85.1% of industrial aluminum, 14.8% of industrial silicon, 0.1% of modificator, and set aside, wherein the modificator is Sr;

[0059] 2) Put the aluminum powder in a resistance furnace, heat it until it melts, add industrial silicon and a modifier, mix well, and keep it at 750°C for 90 minutes to obtain an aluminum-silicon alloy melt;

[0060] 3) cooling the aluminum-silicon alloy melt obtained in step 2) in a graphite crucible with a diameter of 5 mm at a cooling rate of 100° C. / s to obtain an aluminum-silicon alloy;

[0061] 4) cutting the aluminum-silicon alloy obtained in step 3) into small pieces, placing it in dilute hydrochloric acid with a mass concentration of 10%, and chemically etching it for 120 hours to obtain the etched aluminum-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com