Preparation methods of three-dimensional flexible transparent electrode and modified inversion solar cell

A technology of solar cells and transparent electrodes, which is applied in the manufacturing/processing of organic semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of large square resistance of electrodes, difficult to meet the requirements of solar cells, etc., to increase the effective area and improve the contact area. , reduce the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

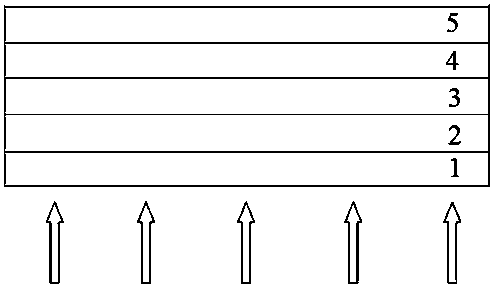

[0021] The invention provides a method for preparing a three-dimensional flexible transparent electrode. The three-dimensional flexible transparent electrode is formed on a PET substrate. The polyacrylate layer is subjected to plasma treatment; (2) The PET substrate after plasma treatment is subjected to magnetron sputtering treatment, and the lower layer of ZnO film, AgO x film and the upper ZnO film to form a three-dimensional flexible transparent electrode on the PET substrate.

[0022] Step (1) includes placing the PET substrate in a PECVD chamber, and performing Ar plasma bombardment on the thermally crosslinked polyacrylate layer, so that the thermally crosslinked polyacrylate layer forms protrusions; the bombarded radio frequency frequency is 13.56 MHz, and the Ar The working frequency is 200W, the working air pressure is 22.7Pa, and the bombardment time is 3min.

[0023] In step (1), the thickness of the PET substrate is 75 μm, and the thickness of the heat-crosslinke...

Embodiment 1

[0036] The preparation method of the three-dimensional flexible transparent electrode of this embodiment comprises the following steps:

[0037] (1) The thickness of the PET substrate is 75 μm, and there is an 8 μm thick thermally crosslinked polyacrylate layer on the PET substrate; the PET substrate is placed in a PECVD chamber, and the thermally crosslinked polyacrylate layer is bombarded with Ar plasma to make the heat The cross-linked polyacrylate layer forms protrusions, the bombardment radio frequency frequency is 13.56 MHz, the Ar operating frequency is 200W, the working pressure is 22.7Pa, and the bombardment time is 3min.

[0038] (2) Perform magnetron sputtering treatment on the PET substrate after plasma treatment, and form the lower layer ZnO film, AgO x film and the upper ZnO film to obtain a three-dimensional flexible transparent electrode; specifically: under radio frequency conditions, use 200W power, 0.4Pa working pressure, and 60sccm Ar flow rate to plate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com