Preparation method of N-methyl-p-anisidine

A technology of p-methoxyaniline and methyl, which is applied in the field of preparation of N-methyl-p-methoxyaniline (NMPA), can solve problems such as high-pressure hydrogen, achieve less by-products, economical and easy atom utilization, and Equipment requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

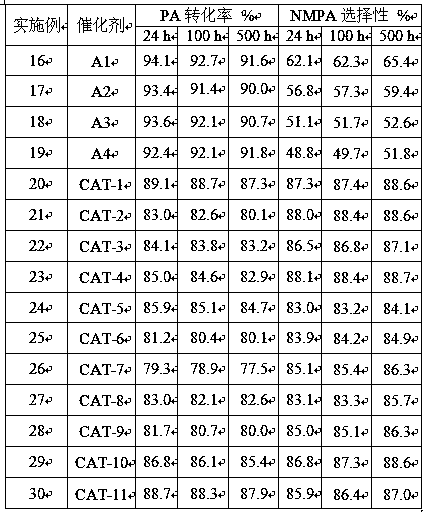

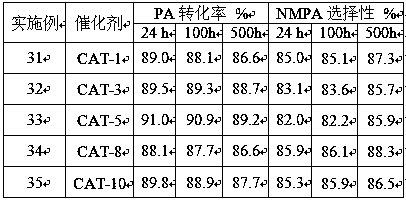

Examples

Embodiment 1

[0022] Weigh 1 mmol of copper nitrate trihydrate, 10 mmol of nickel nitrate hexahydrate, and 5 mmol of zinc nitrate hexahydrate into 100 mL of deionized water, stir and dissolve in a 250 mL round bottom flask, add 50 mL of 0.4 M sodium carbonate solution dropwise Stir well into the above solution, 50 o C aged for 3 h, centrifuged and washed with deionized water until neutral, and the precipitate was 100 o C drying 3 h, muffle furnace 400 o C roasting for 2 h, using a temperature-programmed reduction furnace, at a hydrogen flow rate of 10 mL / min, 10 o C / min heating up to 450 o C, at 450 o C for 2 h to obtain prefabricated catalyst A1.

Embodiment 2

[0024] Weigh 3 mmol of copper nitrate trihydrate, 6 mmol of nickel nitrate hexahydrate, and 10 mmol of zinc nitrate hexahydrate into 100 mL of deionized water, stir and dissolve in a 250 mL round bottom flask, add 60 mL of 1 M ammonia solution dropwise to the above Stir well in the solution, 50 o C aged for 3 h, centrifuged and washed with deionized water until neutral, and the precipitate was 100 o C drying 3 h, muffle furnace 400 o C roasting for 2h, using a temperature-programmed reduction furnace, at a hydrogen flow rate of 10 mL / min, 10 o C / min heating up to 450 o C, at 450 o C for 2 h to obtain prefabricated catalyst A2.

Embodiment 3

[0026]Weigh 10 mmol of copper nitrate trihydrate, 2 mmol of nickel nitrate hexahydrate, and 2 mmol of zinc nitrate hexahydrate into 100 mL of deionized water, stir and dissolve in a 250 mL round bottom flask, and add 45 mL of 0.8 M sodium hydroxide solution dropwise to the above solution Stir well in medium, 50 o C aged for 3h, centrifuged and washed with deionized water until neutral, and the precipitate was 100 o C drying 3 h, muffle furnace 400 o C roasting for 2 hours, using a temperature-programmed reduction furnace, at a hydrogen flow rate of 10 mL / min, 10 o C / min heating up to 450 o C, at 450 o C for 2 h to obtain prefabricated catalyst A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com